Noncircular part deburring robot based on force compensation

A deburring and robot technology, applied in the direction of machine tools, grinding racks, grinding workpiece supports, etc. suitable for grinding workpiece edges, can solve the problem of no cutting force, achieve uniform deburring cutting, and ensure deburring quality , to avoid the effect of not reflecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

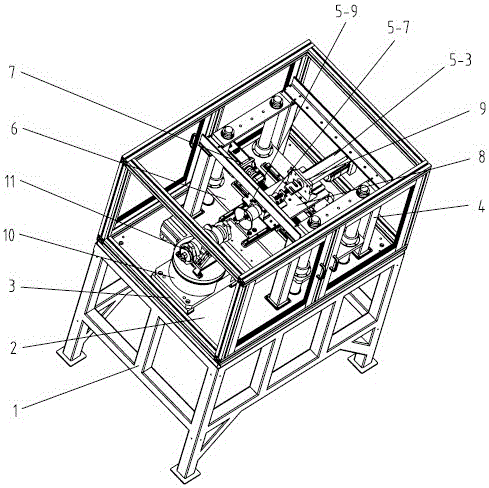

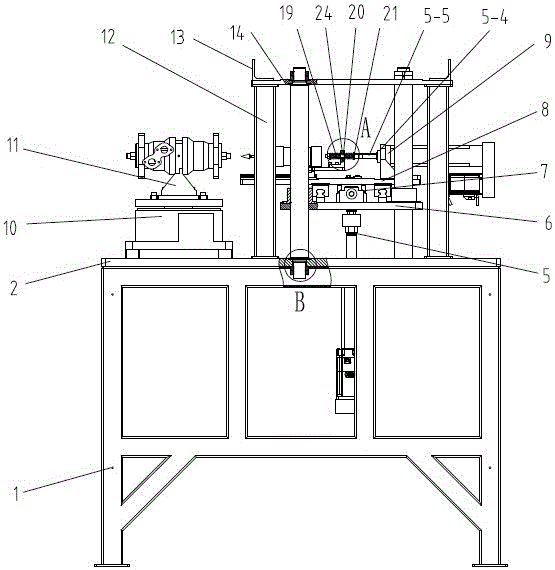

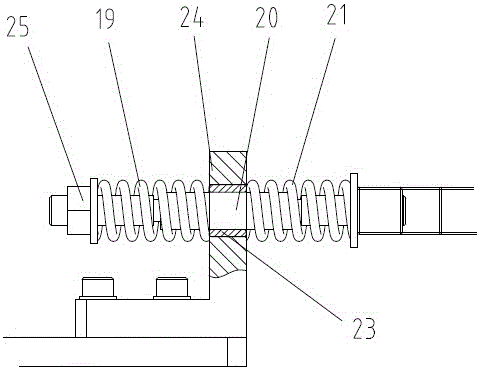

[0022] The basic composition of the non-circular part deburring robot based on force compensation of the present invention can be found in figure 1 , figure 2 , the base plate 2 in the middle of the frame 1 is equipped with four guide columns through the fixed guide frame 4, and the base plate 2 of the frame 1 is also equipped with a symmetrical tooling 11 located on the side of the fixed guide frame 4 as a workpiece clamping tool, and a Y-axis The vertically moving mounting plate 6 driven by the servo motion device 5, the guide column passes through the vertically moving mounting plate 6, and forms a vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com