A multi-purpose split pulse dust collecting trolley

A split-type, dust-collecting technology, used in multi-axis trolleys, trolleys, motor vehicles, etc., can solve the problems of inconvenient movement, complex structure, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

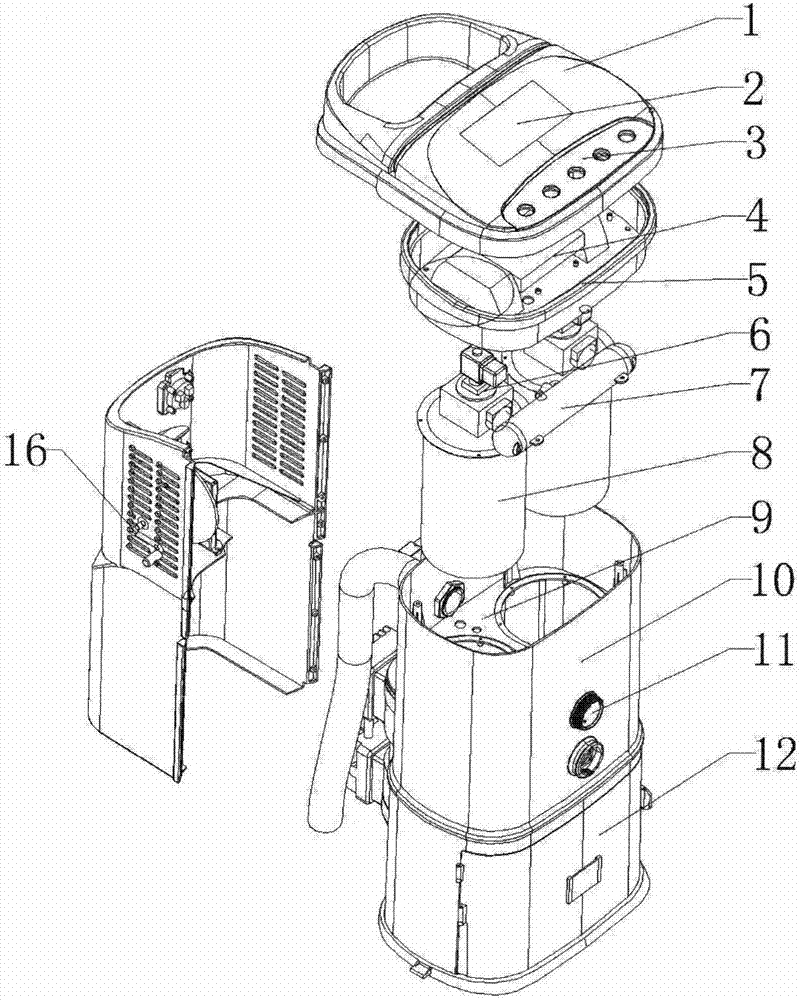

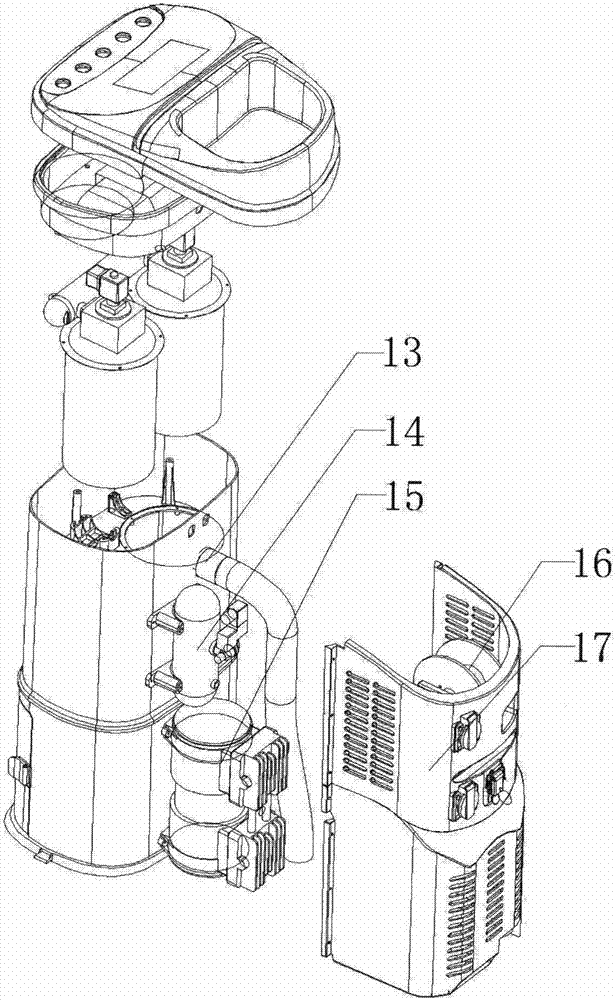

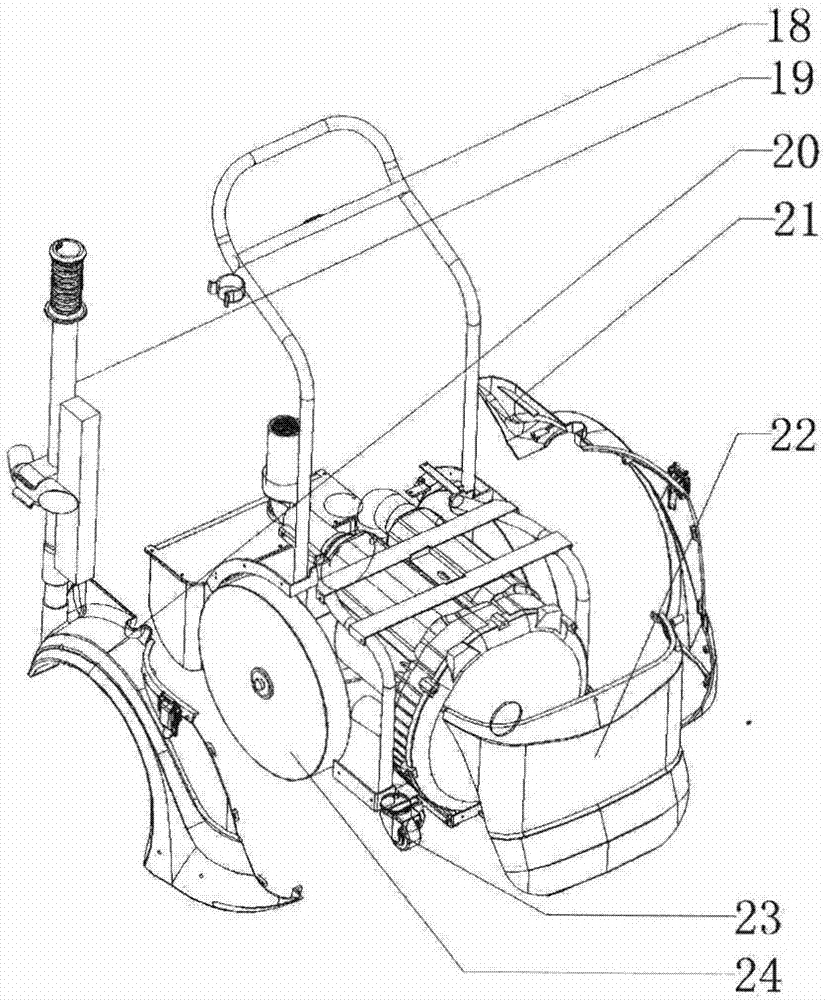

[0041] Such as Figure 1-7 As shown, a multi-purpose split pulse dust collection trolley that can move at any time has a load-bearing cart platform 18, which carries a dust collection bucket. The bottom of the dust collection trolley carrying platform is provided with multiple a universal roller. The cart platform 18 rear end of carrying forms the cart handle.

[0042] exist figure 1 Among them, the rear end of the cart platform carried is provided with large casters 24, and the front end is provided with steerable small universal wheels 23. The upper part of the dust collection barrel has a bung, and a loam cake 1 is closed on the bung. The upper surface of the loam cake 1 is provided with a key switch 3, a timer and a display screen 2 for opening the machine and controlling each component. The timer and display screen 2 are used for timing, full-load call display and other function display when the machine is working. A space or a groove is also provided on the upper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com