A kind of self-flowing air separation grain cleaning device

A self-flow and air separation technology, applied in chemical instruments and methods, separation of solids from solids by air flow, separation of solids, etc., can solve the problem of insufficient flying effect, inconvenient operation and use, and low separation efficiency. and other problems, to achieve the effect of simple structure, convenient movement and operation, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

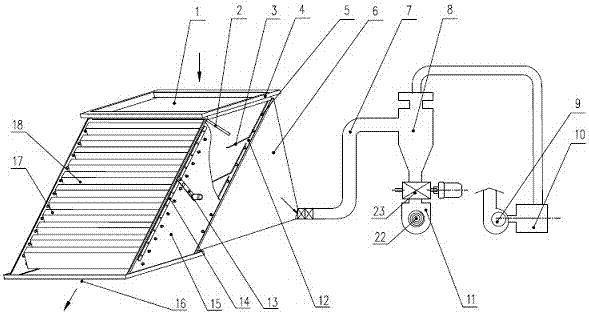

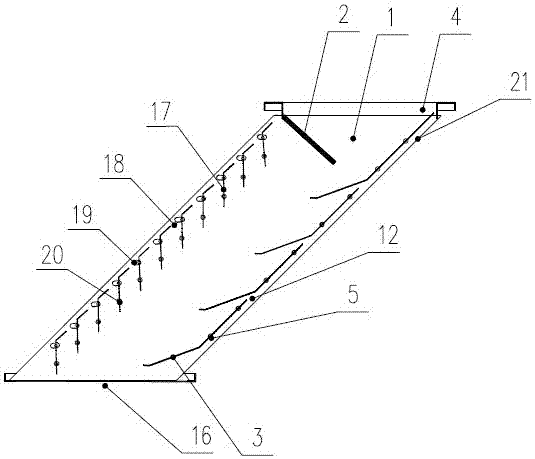

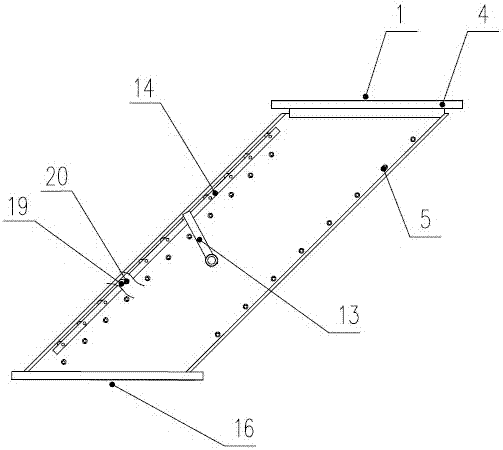

[0022] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0023] The embodiment of the present invention includes two parts: a screen box and a suction and dust removal device.

[0024] The sieve box is a parallelogram rhombic cubic box structure, the upper end of the box body 4 is the grain inlet 1, the lower end is the grain outlet 16, the front side is a louver type air inlet structure, and the rear side is a bent plate structure , the left and right sides are side plates 15 that can support blades 17 and bent plates 3 .

[0025] The bent plate structure is formed by arranging three horizontally striped bent plates in steps. The cross section of the bending plate 3 is “J” shape, the left and right ends of each J-shaped bending plate 3 are respectively fixed on the side plate 15 of the box by the screw nut 5, and the front end of the J-shaped bending plate 3 hooks forward The horizontal lines are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com