Covering cap structure for aircraft maintenance

A technology for aircraft and flaps, which is applied to aircraft parts, aircraft accessories, fuselages, etc. It can solve the problems of increasing the gap between the flap and the flap and reducing the speed, so as to achieve convenient use and maintenance, realize error-proof design, and prevent loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

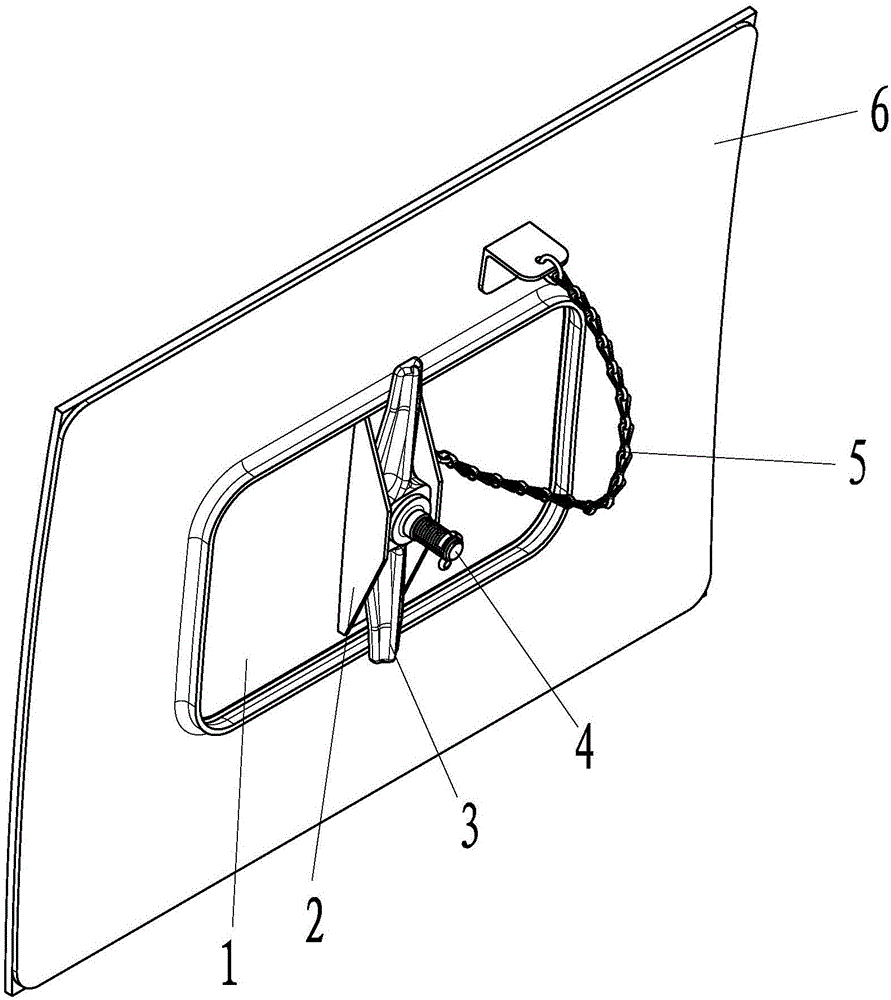

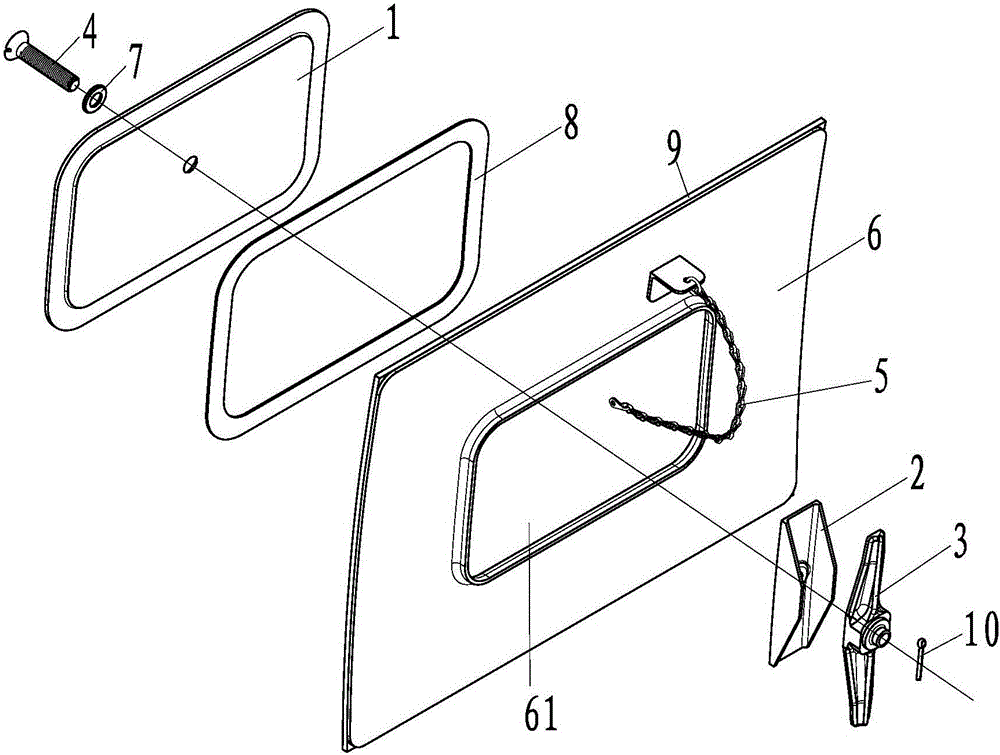

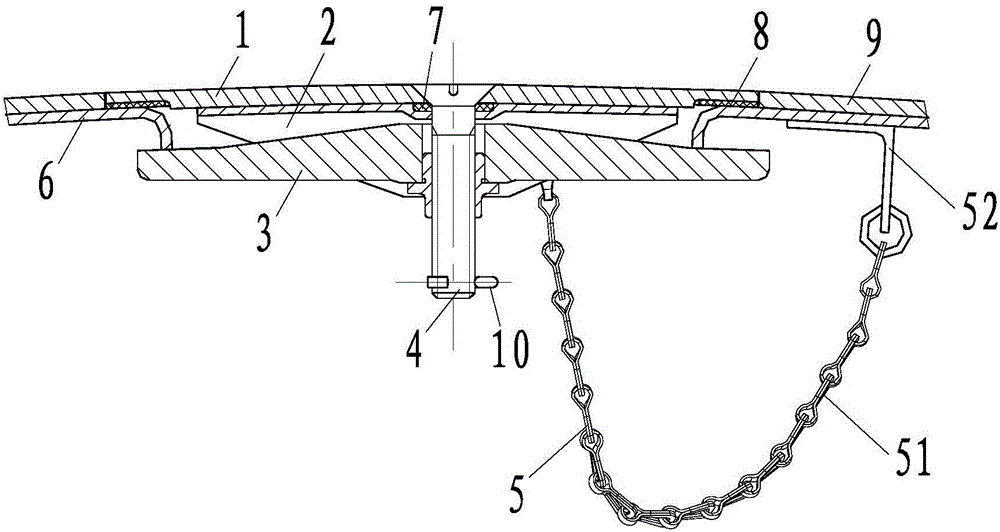

[0016] As shown in the figure, the aircraft maintenance cover structure with electromagnetic protection function of the present invention includes an aircraft skin 9, a reinforced opening frame 6, a cover plate 1, a limit stopper 2, a dead bolt assembly 3 and a lock shaft 4, the The front of the cover plate 1 matches the skin of the theoretical shape of the aircraft. There is a countersunk lock hole 11 in the middle of the cover plate 1. There is a sunken L-shaped groove 12 on the back edge of the cover plate 1. In addition, a conductive rubber strip 8 is connected to the L-shaped groove. 12 matching, the limit stopper 2 is a groove-shaped part, riveted on the reverse side of the cover plate 1, the two sides of the limit stopper have limit flanges 21, and the center of the limit stopper 2 has a sunken hole 22. There is a conductive rubber ring 7 to match the sunken hole 22. The deadbolt assembly 3 is composed of a deadbolt 31 and a threaded bushing 32. There is a connecting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com