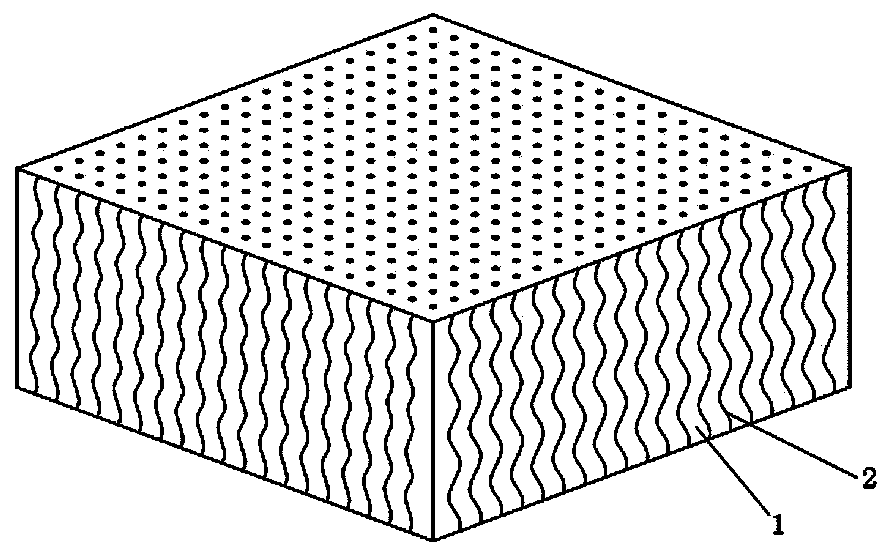

Sponge type directionally-conductive rubber and preparation method thereof

A conductive rubber and sponge technology, applied in the field of conductive rubber, can solve the problems of long-term use of equipment, inability to meet lightweight requirements, unbalanced compression ratio, etc., to avoid the reduction of electrical properties, reduce density, and improve mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

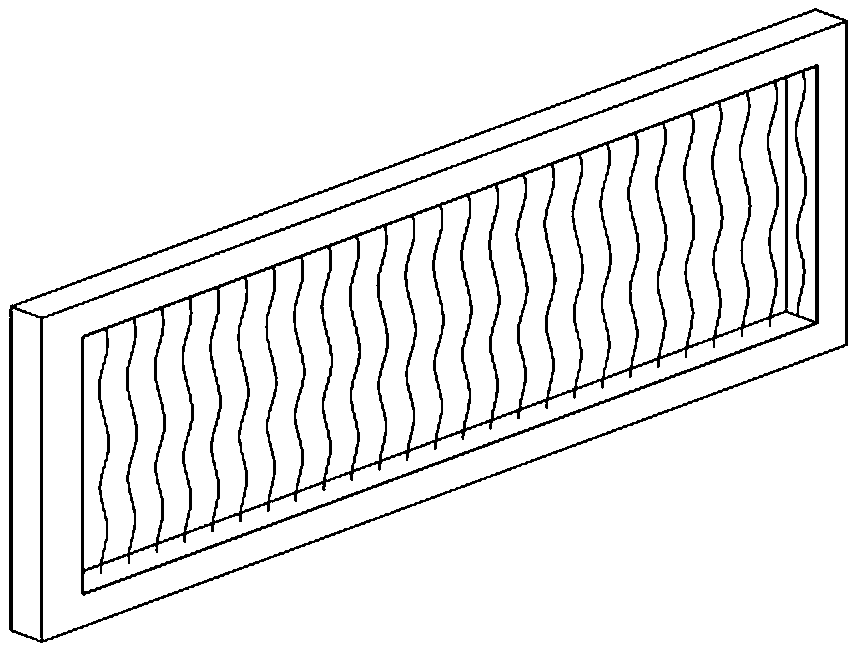

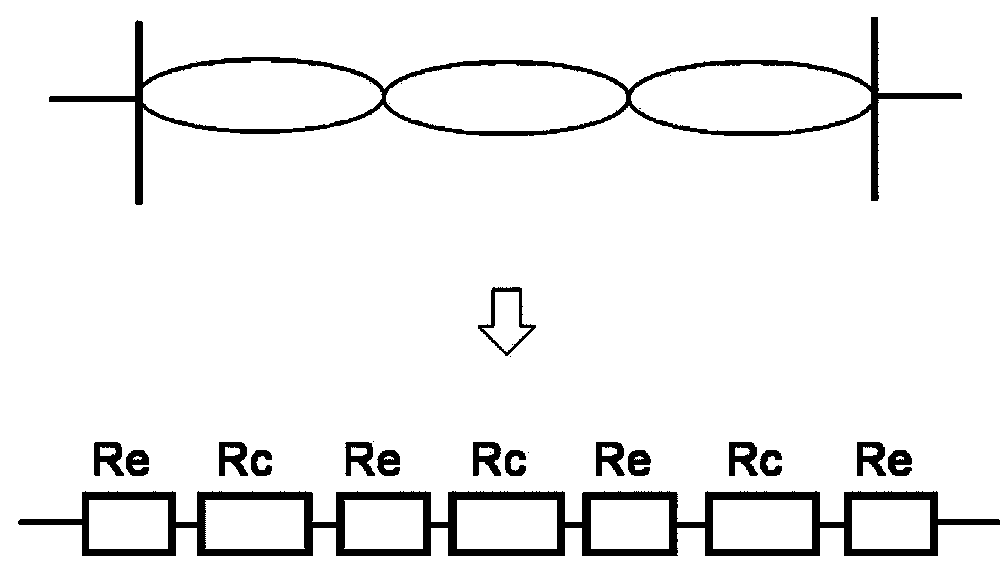

[0036] (1) Wire arrangement: fix the wavy Monel wires on the frame at equal distances, the diameter of the Monel wires is 0.12mm, the distance between the metal wires is 1mm, and the thickness of the fixed frame is 1mm.

[0037] (2) Pretreatment: Use the spraying process to evenly spray the prepared coupling agent solution on the surface of the Monel silk, the spray gun pressure is 0.2MPa, and the spraying time is 30s. After the spraying is completed, put the Monel silk into the oven and set the temperature at 125°C. Dry for 2 hours, the coupling agent is silane coupling agent kh560, and the concentration of the configuration solution is 5%.

[0038] (3) Frame fixing: The pretreated Monel wire frames are tightly stacked in the mold along the same direction, the stacking length is 0.8m, and the gaps are sealed with a sealant after sealing.

[0039] (4) Pouring molding: Inject silicone rubber into the mold with a glue injection machine. After pouring, vulcanize at room temperatu...

Embodiment 2

[0042] (1) Arranging wires: fix the wavy tinned phosphor bronze wires on the frame at equal distances, the diameter of the tinned phosphor bronze wires is 0.1mm, the distance between the wires is 1mm, and the thickness of the fixed frame is 1mm.

[0043] (2) Pretreatment: Spray the prepared coupling agent solution evenly on the surface of tin-plated phosphor bronze wire by spraying process, the spray gun pressure is 0.2MPa, and the spraying time is 30s. After spraying, put the tin-plated phosphor bronze wire into the oven to set The temperature is 130°C, and it is dried for 3 hours. The coupling agent is silane coupling agent kh560, and the concentration of the configuration solution is 5%.

[0044] (3) Frame fixing: The pretreated tin-plated phosphor bronze wire frames are tightly stacked in the mold along the same direction, the stacking length is 1m, and the gaps are sealed with a sealant after sealing.

[0045] (4) Pouring molding: Inject silicone rubber into the mold with...

Embodiment 3

[0048] (1) Wire arrangement: fix the wavy aluminum alloy wires on the frame at equal distances, the diameter of the aluminum alloy wires is 0.15mm, the distance between the aluminum alloy wires is 1mm, and the thickness of the fixed frame is 1mm.

[0049] (2) Pretreatment: Spray the prepared coupling agent solution evenly on the surface of the aluminum alloy wire by spraying process, the spray gun pressure is 0.2MPa, and the spraying time is 30s. Dry for 4 hours, the silane coupling agent kh560 is used as the coupling agent, and the concentration of the configuration solution is 5%.

[0050] (3) Frame fixing: The pretreated aluminum alloy wire frames are tightly stacked in the mold along the same direction, the stacking length is 1m, and the gaps are sealed with a sealant after sealing.

[0051] (4) Pouring molding: Inject silicone rubber into the mold with a glue injection machine. After pouring, vulcanize at room temperature for 48 hours. The silicone rubber is Hangzhou Zhij...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com