Fully automatic bag packaging flexible production line

A flexible production line, fully automatic bag-type technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of lack of data storage, collection, correction functions, inability to adapt to social development requirements, and single product packaging specifications. Quick response to customer needs, strong flexibility and economy, the effect of agile production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

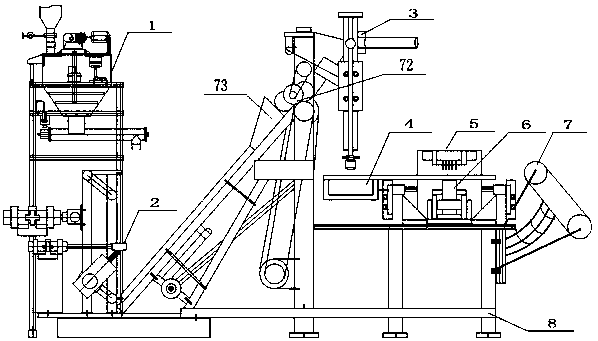

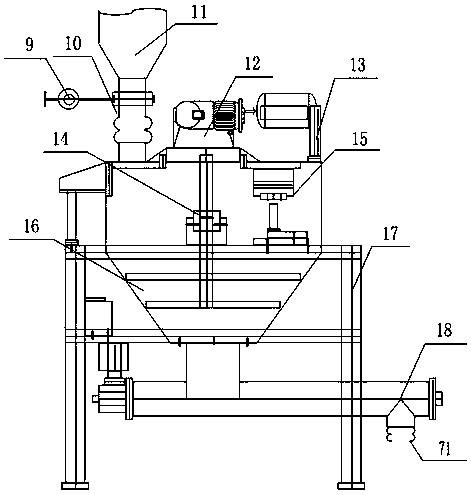

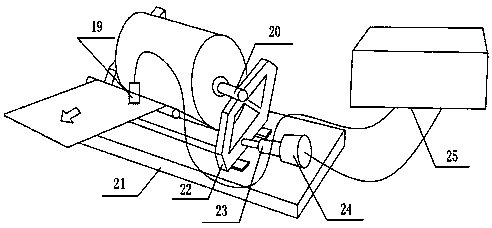

[0039] A fully automatic bag-type packaging flexible production line, including a frame 8, a packaging material unwinding device 7, a sealing and cutting device 6, an inkjet coding device 5, a bag storage table 4, a bag picking and feeding device 3, a picking device The bag device 2 and the quantitative unloading device 1, the packaging material unwinding device 7, the sealing and cutting device 6 and the bag storage table 4 are arranged in sequence, and the sealing and cutting device 6 is equipped with an inkjet printer on the top. A code device 5, the top of the bag storage platform 4 is provided with a bag-taking and bag-feeding device 3, the bag-taking and bag-feeding device 3 is connected to the bag-picking device 2 through the bag conveyor 72, and the top of the bag-picking device 2 is provided with a quantitative unloading device 1;

[0040] The bag-taking devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com