A magnetic shock separation centrifugal water treatment reactor

A reactor and separation technology, which is applied in the field of magnetic shock separation centrifugal water treatment reactors, can solve problems such as reducing water head and blocking the potential gap of sewage treatment grids, and achieves the effect of preventing blockage and improving decomposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

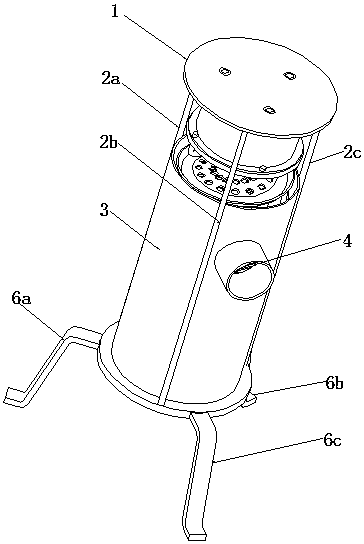

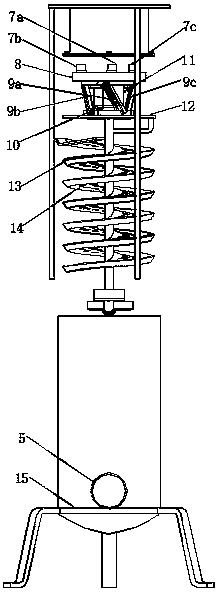

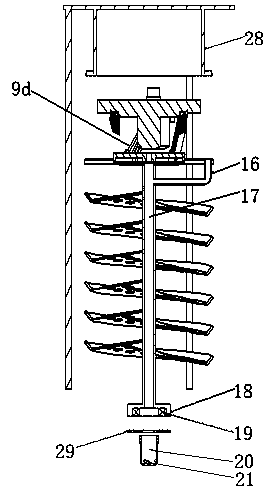

[0022] Below in conjunction with accompanying drawing, the present invention is described in detail below.

[0023] attached figure 2 It is a diagram showing the centrifugal aeration mechanism of the first embodiment of the present invention. After the compressed air is passed through the air inlet pipe 16, after passing through the central column 17 and the central rotating shaft 20, the first Laval nozzle 23, the second Laval nozzle 25 and the third Laval nozzle 27, the central shaft 20 rotates around the center under the reaction force of the water flow, and the sewage in the reactor 3 is stirred to make it generate a vortex, and the ejected gas becomes bubbles and is discharged upward from the bottom of the reactor; The air pipe 16 is installed on the end surface of the vibrating plate 12 and is connected with the compressed air outside. The central column 17 is a hollow tube, one end is connected with the vibrating plate 12, and the other end is equipped with a bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com