Water treatment equipment for adjusting aeration intensity based on water inlet load

A technology of water treatment equipment and aeration intensity, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, multi-stage water treatment, etc., can solve the problem of uneven temperature of wastewater, small hydraulic scouring effect, biofilm Blockage and other problems, to achieve the effect of promoting the oxidation reaction process, increasing the aeration rate, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

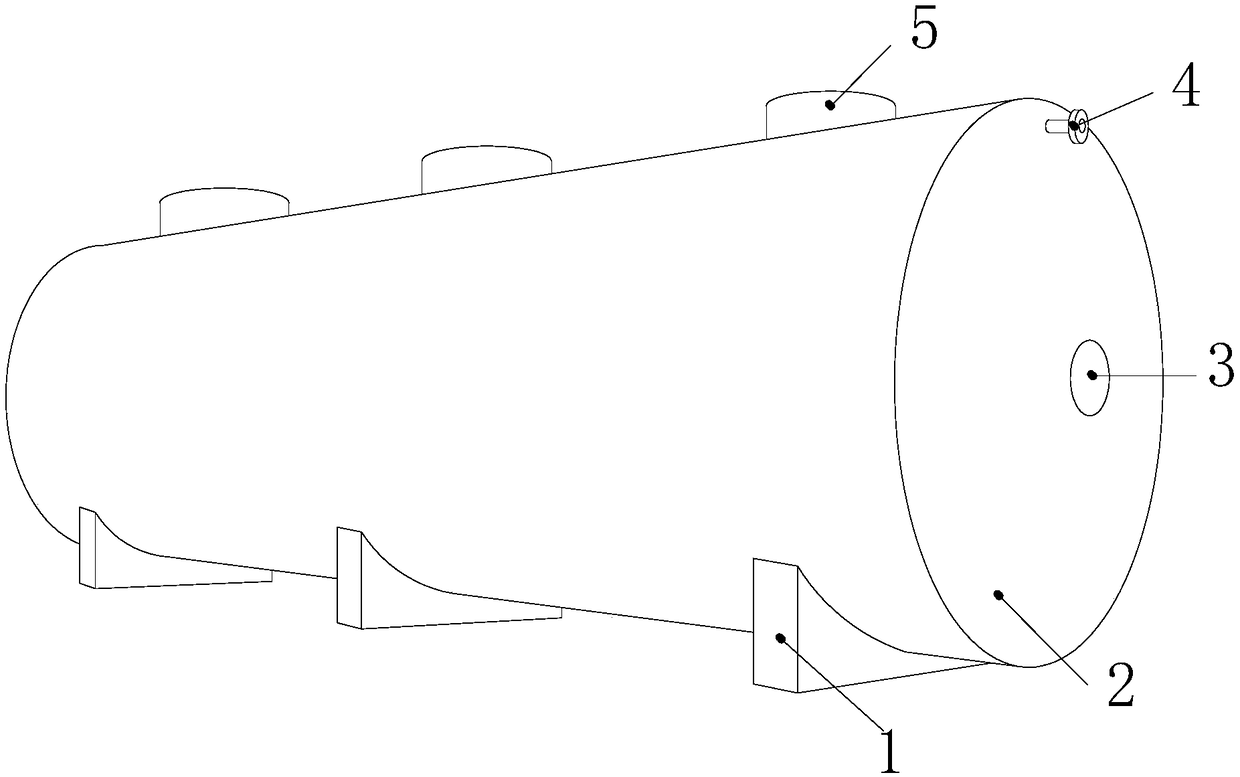

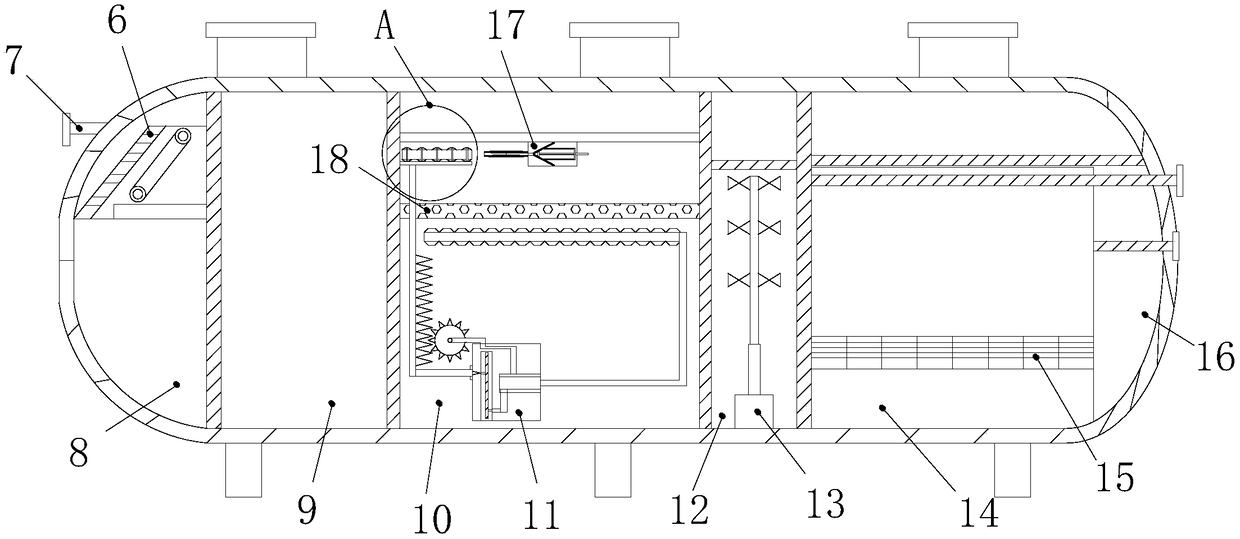

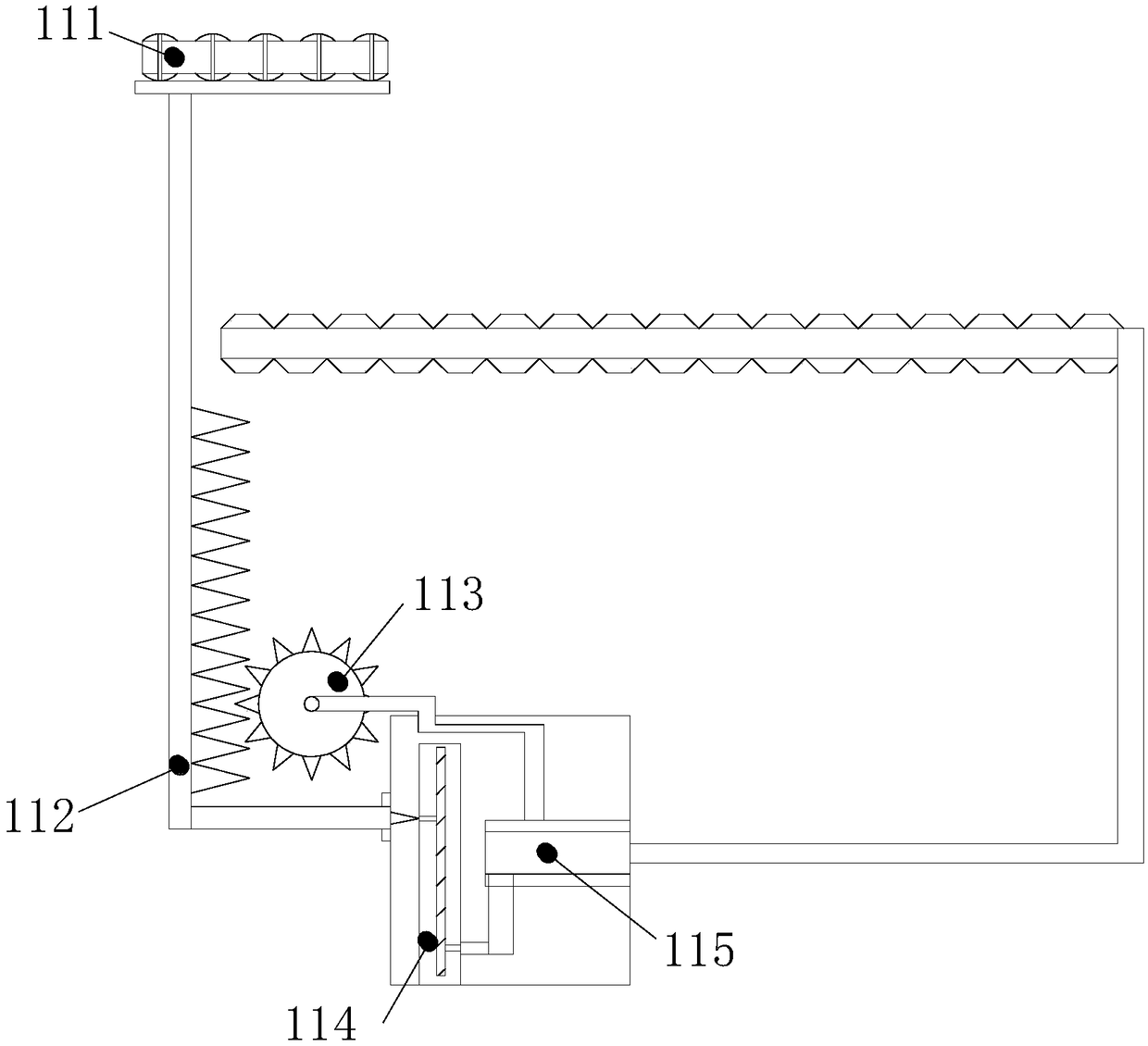

[0038] see Figure 1-Figure 6 , the present invention provides a kind of water treatment equipment for adjusting the intensity of aeration based on the influent load: its structure includes a support column foot 1, a treatment box 2, a tap water outlet 3, a backwash pipe 4, a maintenance pipe 5, and a mechanical grille 6 , raw water inlet 7, pretreatment chamber 8, first contact oxidation chamber 9, second contact oxidation chamber 10, self-regulating aeration device 11, mixing reaction chamber 12, agitator 13, precipitation chamber 14, attachment partition 15, water outlet Cavity 16, water temperature sensing device 17, biofilm plate 18, the support column foot 1 is provided with three and vertical nails are connected below the processing box bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com