Treatment method of oily sludge

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve secondary pollution and other problems, and achieve secondary pollution prevention and mineral element content High and reduce the effect of recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

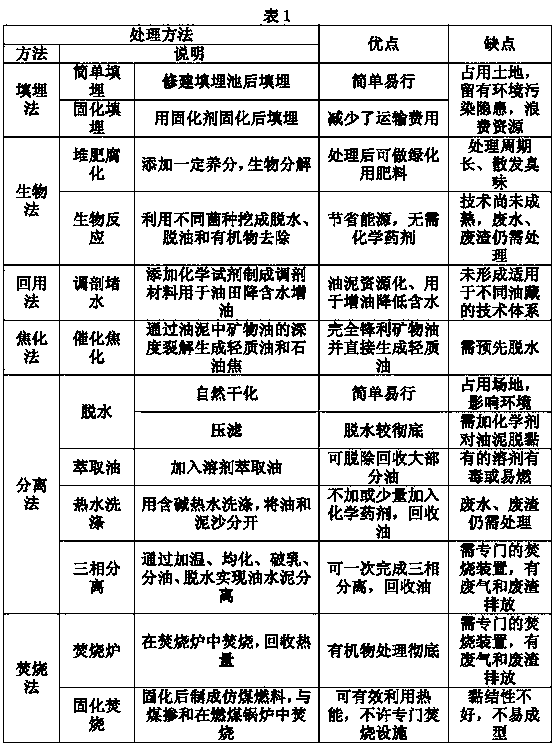

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: The treatment method of the oily sludge is carried out according to the following steps: the first step is to fluidize the oily sludge to obtain a mixed fluid; the second step is to heat and condense the mixed fluid in order to obtain Oil-water mixture and oil sludge, while heating the mixed fluid, stir the mixed fluid, wherein, the stirring speed is 1.5 rpm to 10 rpm, the heating temperature is 50°C to 500°C, and the condensation temperature is 10°C to 32°C; in the third step, the sludge is heated at a high temperature to obtain furnace ash, and the temperature of the high temperature heating is 600°C to 1000°C. According to the treatment method for oily sludge described in this example, the oily sludge A is treated, the oil content of the oily sludge A is 8% to 35% (volume percentage), and the water content is 30% to 40% (volume percentage ), the solid content rate is 30% to 45% (volume percentage), and the recovery rate of the oil-water mixture obtained...

Embodiment 2

[0015] Embodiment 2: The treatment method of the oily sludge is carried out according to the following steps: the first step is to fluidize the oily sludge to obtain a mixed fluid; the second step is to heat and condense the mixed fluid in order to obtain Oil-water mixture and oil sludge, while heating the mixed fluid, stir the mixed fluid, wherein the stirring speed is 1.5 rpm or 10 rpm, the heating temperature is 50°C or 500°C, and the condensation temperature is 10°C or 32°C; in the third step, the sludge is heated at a high temperature to obtain furnace ash, and the temperature of the high-temperature heating is 600°C or 1000°C.

Embodiment 3

[0016] Embodiment 3: The treatment method of the oily sludge is carried out according to the following steps: the first step is to fluidize the oily sludge to obtain a mixed fluid; the second step is to heat and condense the mixed fluid in order to obtain Oil-water mixture and oil sludge, while heating the mixed fluid, stir the mixed fluid, wherein, the stirring speed is 1.5 rpm, the heating temperature is 50°C, and the condensation temperature is 10°C; the third step is to Furnace ash is obtained from oil sludge after high-temperature heating, and the temperature of high-temperature heating is 600°C. According to the oily sludge treatment method described in this example, the oily sludge B is treated. The oily sludge B has an oil content of 16% (volume percentage), a water content of 30% (volume percentage), and a solid content of 34% (volume percentage), the recovery rate of the oil-water mixture obtained after the oily sludge B is treated by the oily sludge treatment method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com