Oolong tea polyphenol and extraction method thereof

An extraction method and technology of tea polyphenols, applied in the field of oolong tea polyphenols and its extraction, to achieve the effects of high extraction efficiency, stable properties, and efficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

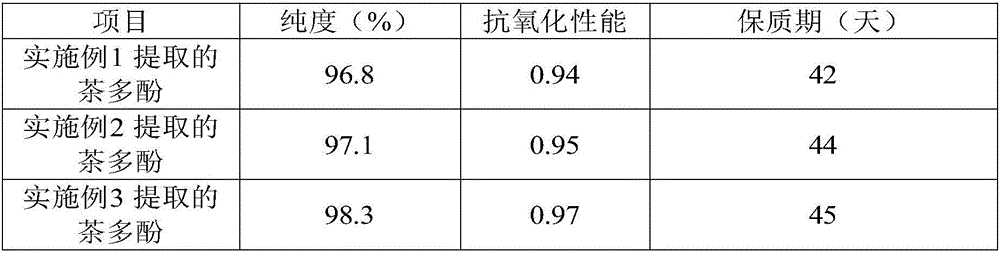

Examples

Embodiment 1

[0036] A kind of extraction method of oolong tea tea polyphenol

[0037] Include the following steps:

[0038] Step S1, disinfection: soak and wash the oolong tea leaves in clear water for 2 hours, remove them and dry them in the sun, and use 1% acetic acid mist to fumigate the oolong tea leaves for 20 minutes;

[0039] Step S2, sterilization: use a 300W ultraviolet lamp to sterilize the sterilized oolong tea leaves for 5 minutes;

[0040] Step S3, enzymatic hydrolysis: put the sterilized oolong tea leaves into an aqueous cellulase solution with a mass fraction of 5%, adjust the pH value of the solution to 4.5 using a sodium dihydrogen phosphate / citric acid buffer solution with a pH of 3.5, and perform enzymatic hydrolysis 3h, after the enzymatic hydrolysis is completed, raise the temperature to 96°C for 25min to inactivate the enzyme, then collect the oolong tea enzymatic hydrolyzate for later use;

[0041] Step S4, preparation of tea polyphenols crude extract: use 0.1% dil...

Embodiment 2

[0045] A kind of extraction method of oolong tea tea polyphenol

[0046] Include the following steps:

[0047] Step S1, disinfection: soak and wash the oolong tea leaves in clear water for 3 hours, remove them and dry them in the sun, and use 10% acetic acid mist to fumigate the oolong tea leaves for 60 minutes;

[0048] Step S2, sterilization: use a 500W ultraviolet lamp to sterilize the sterilized oolong tea leaves for 10 minutes;

[0049] Step S3, enzymatic hydrolysis: put the sterilized oolong tea leaves into a cellulase aqueous solution with a mass fraction of 20%, adjust the pH value of the solution to 6.2 with a sodium dihydrogen phosphate / citric acid buffer solution with a pH of 3.7, and perform enzymatic hydrolysis 8h, after the enzymatic hydrolysis is completed, raise the temperature to 96°C for 25min to inactivate the enzyme, and then collect the oolong tea enzymatic hydrolyzate for later use;

[0050] Step S4, preparation of tea polyphenols crude extract: use 0.5...

Embodiment 3

[0054] A kind of extraction method of oolong tea tea polyphenol

[0055] Include the following steps:

[0056] Step S1, disinfection: soak and wash the oolong tea leaves in clear water for 2.5 hours, remove them and dry them in the sun, and use 5.5% acetic acid mist to fumigate the oolong tea leaves for 40 minutes;

[0057] Step S2, sterilization: use a 400W ultraviolet lamp to sterilize the sterilized oolong tea leaves for 7.5 minutes;

[0058] Step S3, enzymatic hydrolysis: put the sterilized oolong tea leaves into a cellulase aqueous solution with a mass fraction of 12.5%, adjust the pH value of the solution to 5.4 with a sodium dihydrogen phosphate / citric acid buffer solution with a pH of 3.6, and perform enzymatic hydrolysis After 5.5 hours, after the enzymatic hydrolysis is completed, heat up to 96°C for 25 minutes to inactivate the enzyme, and then collect the oolong tea enzymatic hydrolysis solution for later use;

[0059] Step S4, preparation of tea polyphenols crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com