Imitation suede fabric and preparing process therefor

A preparation process and technology of suede, applied in dry cleaning fiber products, fabric surface trimming, weaving and other directions, can solve the problems of polluting the environment and affecting the effect of fabrics, and achieve the effect of good effect, low cost and full cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content, features and effects of the present invention, the following examples are given to describe the present invention in detail.

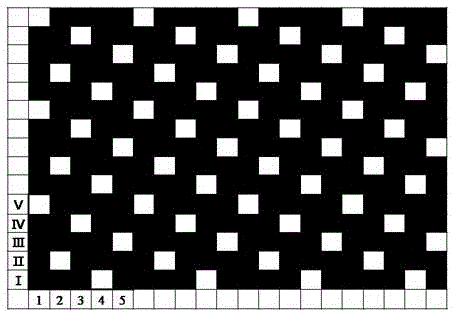

[0027] refer to figure 1 , a suede-like fabric, including warp yarns and weft yarns, the suede-like fabric fabric is made of warp yarns and weft yarns that are up and down and interlaced, and the warp yarns and weft yarns are interwoven into five satin weaves. The minimum five satin weave units of the velvet fabric are interwoven with five warp yarns and five weft yarns, and the five warp yarns of the five minimum satin weave units are all four-up and one-down structures at positions superimposed on each weft yarn, so The five weft yarns of the above-mentioned minimum change unit have a structure of one up and four down at the position superimposed on each warp yarn, wherein the superposition position of the warp yarn on the top is the warp knitting point;

[0028] The warp yarns of the first row of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com