A device for preheating a recovered fiber material to be dispersed

A technology for recycling fibers and heating devices, which is applied in the directions of fiber raw materials, fiber raw material processing, paper recycling, etc., can solve problems such as expensive costs, and achieve the effects of easy maintenance, simple structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

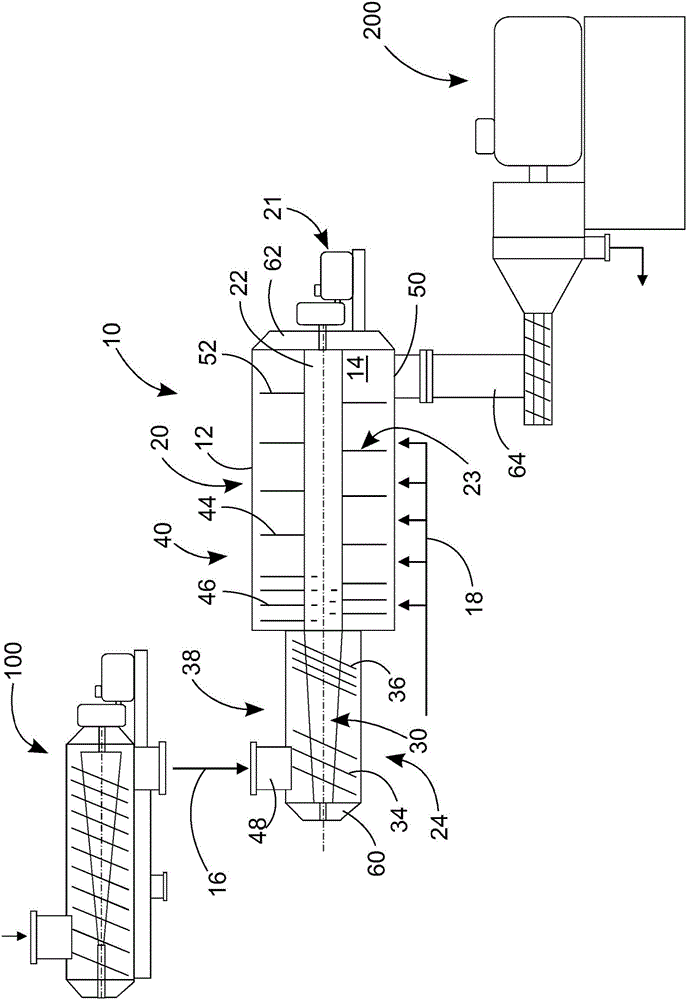

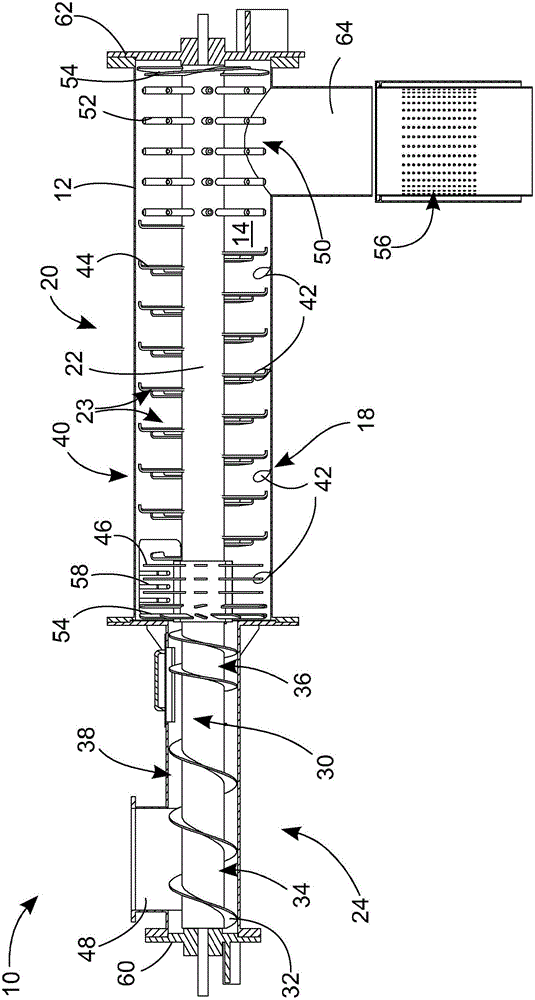

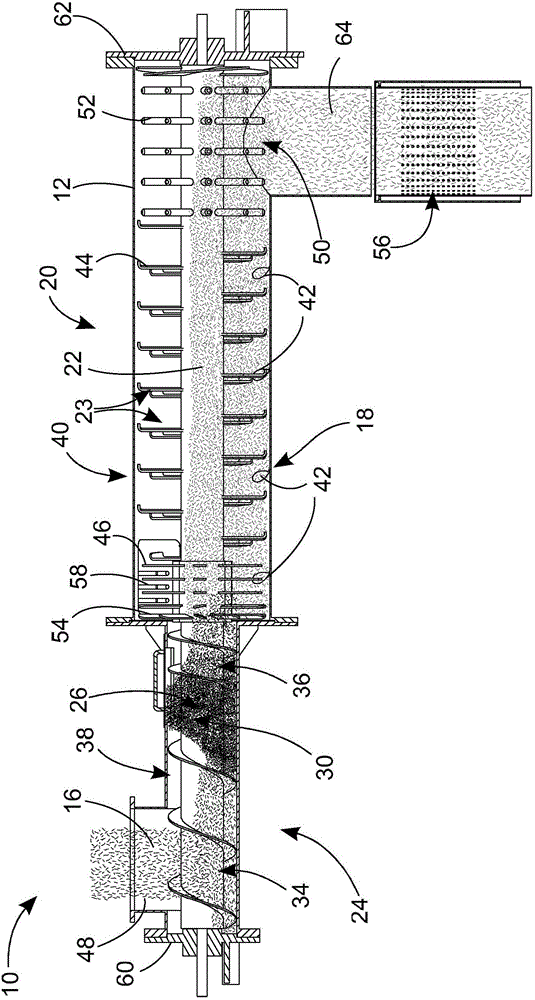

[0031] according to figure 1 The device according to the invention is part of the dispersing process and is placed between the concentrating screw 100 and the disperser 200 during the process. The task of the device 10 is to heat the recycled fiber material to be flowed to the disperser from a temperature of about 20° C. to a temperature of about 100° C. or even 120° C. in order to decompose impurities from the recycled fiber. When recycled fiber material is mentioned in this context, OCC and DIP recycled fibers are preferably meant. The device according to the invention may also be referred to as a preheating facility.

[0032] according to figure 1 , the device 10 is equipped with a frame 12, a heating device 18, a conveying screw 24 and a mixing device 20, within which the Figure 2b Volume 14 of recycled fibrous material. The mixing device 20 is provided in the longitudinal direction with the shaft 22 of the frame 12, with flanking elements 23 arranged on the shaft for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com