Energy collecting device of nonlinear spring

An energy harvesting and nonlinear technology, applied to bridge parts, building components, bridges, etc., can solve the problem that the nonlinear spring does not have a linear frequency, and achieve the effects of flexible layout, good energy transmission, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

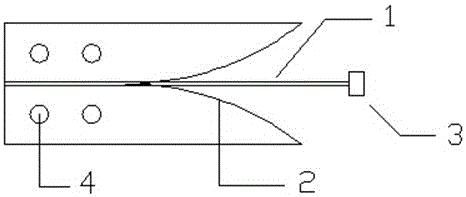

[0016] Embodiment 1: as figure 1 Shown is an implementation example of a nonlinear spring energy harvesting device of the present invention, which mainly includes a cantilever beam 1 , a contact surface 2 , a mass block 3 and a fixing bolt 4 .

[0017] The energy harvesting device is fixed on the structural member by fixing bolts 4, the cantilever beam 1 is a steel strip, the end of the cantilever beam 1 is fixed with a mass block 3, and the root of the cantilever beam 1 is fixed with the upper and lower contact surfaces at a distance to avoid friction slide. The rest of the length of the cantilever beam 1 is separated from the upper and lower contact surfaces. When the end mass oscillates up and down, bending deformation can be generated between the upper and lower contact surfaces, and at the same time, it is in contact with the upper and lower surfaces. The contact surface 2 is symmetrically arranged up and down, and the curvature of the surface changes gradually along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com