Method and system applicable to harmless treatment and sustainable utilization of oil and gas field drilling waste

A technology for the harmless treatment of drilling waste, applied in the field of environmental engineering, can solve the problems of secondary pollution, high economic cost, substandard treatment technology, etc., to reduce treatment costs, solve environmental pollution problems, and achieve sustainable utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

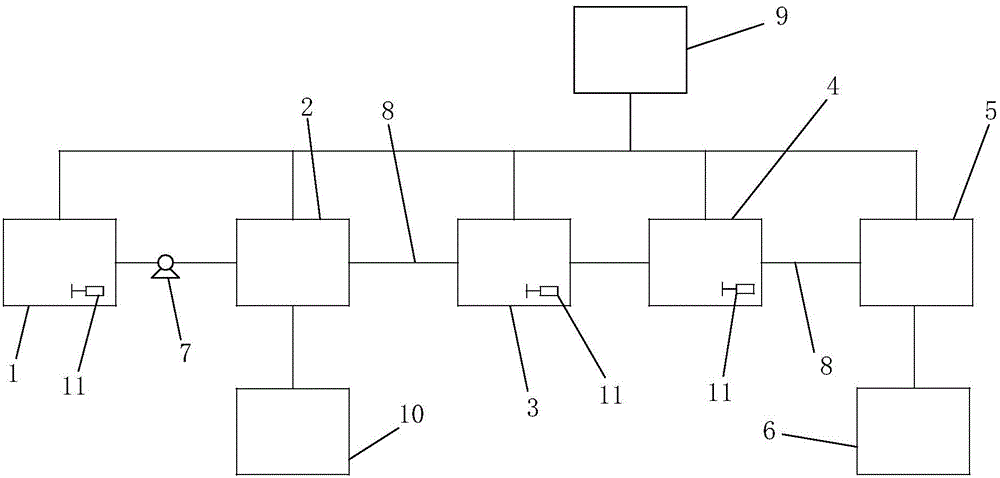

Method used

Image

Examples

Embodiment

[0042] Treat the fracturing flowback fluid produced in a certain area with the method of the present invention, with a designed treatment capacity of 80m³ / d, and operate continuously for 16 hours a day for 2 months;

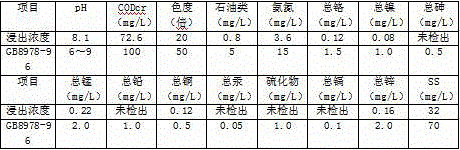

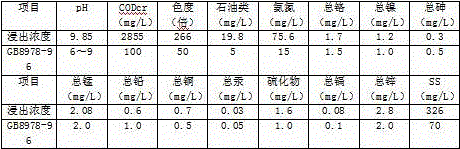

[0043] 1. Drilling waste feed index

[0044] Table 1 Drilling waste feed index

[0045]

[0046] 2. Process operating parameters

[0047] Drilling waste enters the pretreatment device, separation device, harmless treatment device, coagulation treatment device, forming device and maintenance device in sequence;

[0048] Pretreatment: Add 20g / kg of oxidative breaker, 10g / kg of one or more of fatty acid, aliphatic amides or ester dispersants, and 20g / kg of polymer dehydrating agent in sequence under stirring conditions , and fully stirred evenly, and reacted for 20 minutes.

[0049] Separation treatment: The pretreated drilling waste is subjected to solid-liquid separation.

[0050] Harmless treatment: Send the separated solid phase into the harmless treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com