Balanced injection and recovery method of thickened oil thermal recovery horizontal well

A technology for thermal recovery of heavy oil and horizontal wells, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of affecting the productivity of horizontal wells, complicated construction procedures, and uneven production of horizontal well sections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Step 1: Before the completion of the horizontal well, design the horizontal well section in sections according to the permeability and oil saturation distribution of the horizontal section;

[0021] Step 2: Combine the steam injection, production, and wellbore flow in the horizontal section designed in step 1, and design the flow intensity of the horizontal section;

[0022] Step 3: Design the sand-retaining precision of the sand control screen according to the distribution of formation sand particle size;

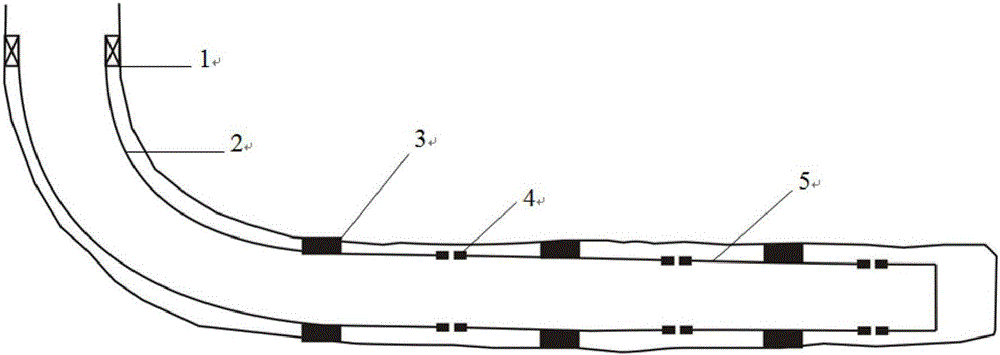

[0023] Step 4: According to the design results of steps 1 to 3, design and run the completion string 8; The flow regulating sand control screen 5 with the flow control device 4 is assembled; the high temperature resistant open hole external packer 3 is an expansion seal, the suspension packer 1 is a suspension seal, and the completion string 8 The whole is suspended seal;

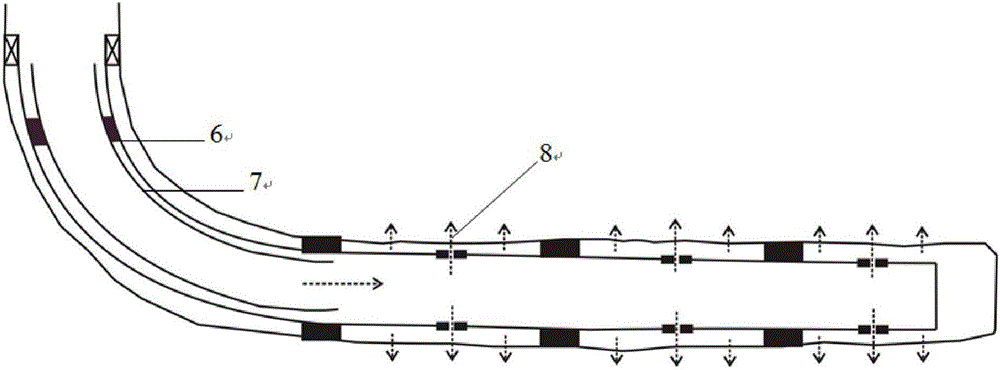

[0024] Step 5: Design and run the integrated injection-production string 7, inject steam in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com