High pressure manifold device for carbon dioxide dry fracturing

A high-pressure manifold and carbon dioxide technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of labor-intensive operators, complex connection process of construction pipelines, and large damage to high-pressure pipe valves. Achieve the effect of reducing labor intensity, meeting the operation requirements and normal construction requirements on site, and reducing the risk of construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

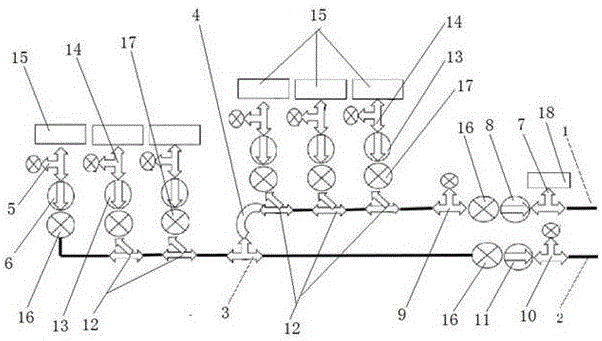

[0024] In order to solve the existing problems in the existing carbon dioxide dry fracturing operation, such as complex construction pipeline connection process, large damage to high-pressure pipe valve parts, and labor-intensive operators, this embodiment provides the following figure 1 A carbon dioxide dry fracturing high-pressure manifold device shown in the figure includes a main line 1 and a main line 2, one end of the main line 1 and one end of the main line 2 are respectively connected to the Christmas tree, A T-shaped tee 3 is connected in series in the middle section of the main line 2 of the II route. The T-shaped tee 3 is connected to the other end of the main line 1 of the I route through a double-female oil short-circuit 4, and the other end of the main line 2 of the II route is connected in series. Check valve one 6, check valve one 6 is connected with main press car 15 through T-type tee one 5;

[0025] The main line 1 of road I is connected in series with T-typ...

Embodiment 2

[0033] On the basis of Example 1, the T-shaped tee 27 adopts a 3*2*3-inch structure. In order to monitor the real-time pressure of the high-pressure pipeline in the fracturing construction, the 2-inch buckle of the T-shaped tee 27 is connected with Pressure sensor 19.

Embodiment 3

[0035] On the basis of Example 1, between the check valve two 8 and the T-type tee three 9, between the check valve one 6 and the manifold tee 12 on the main line 2 of the II road, between the check valve three A 3-inch cock-16 is respectively connected in series between the manifold tee 12 on the main line 2 of the 11 and II road. A 3-inch cock two 17 is connected in series between the inclined pipe port of each manifold tee 12 and the check valve four 13. Each pipeline is isolated with a 3-inch cock and depressurized with a 2-inch cock, which solves the risk of pipeline puncture or carbon dioxide freezing and gasification in some pipelines;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com