An integral double-layer low-pressure inner cylinder of a steam turbine

An integrated steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as deformation and leakage of low-pressure inner cylinders, and achieve the effects of reduced thermal stress, innovative design, and reduced number of openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

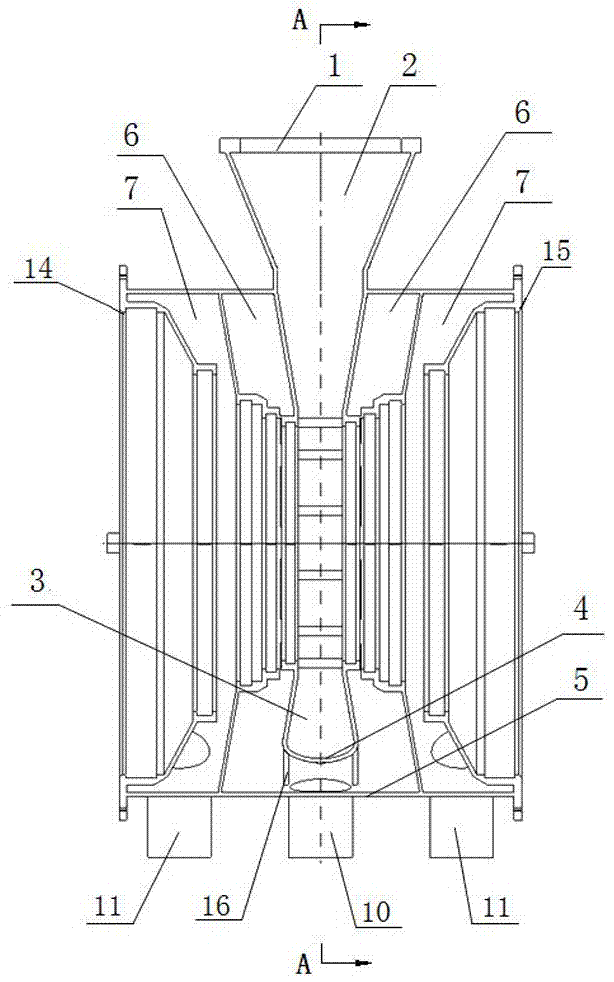

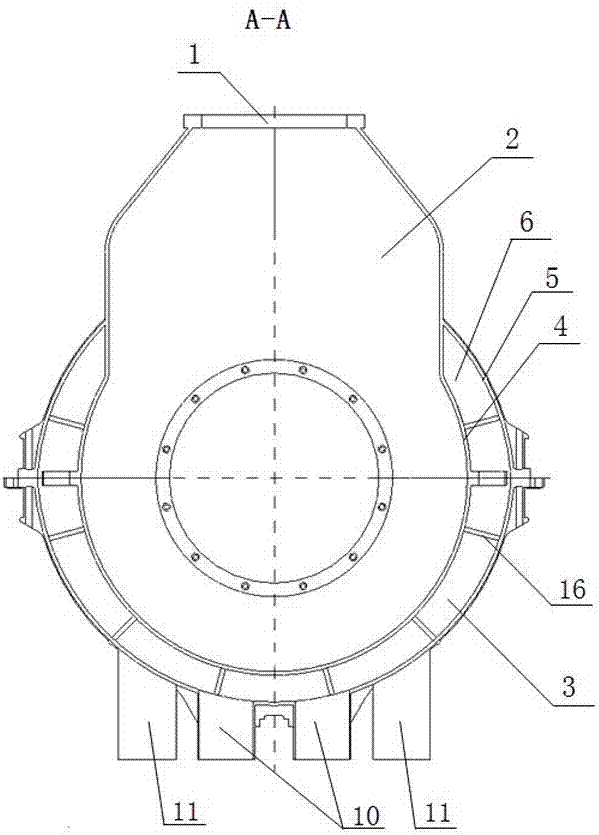

[0028] like figure 1 , figure 2 As shown, when the double-layer integral low-pressure inner cylinder is arranged according to the two-stage regenerative steam extraction, it is left and right symmetrical along the center line of the steam inlet chamber 2; The steam chamber 6; the left and right sections of the inner inner cylinder 4 and the partition cover are all disconnected at the low-pressure secondary heat extraction port 11, forming the left and right low-pressure secondary heat extraction chambers 7.

[0029] The upper half of the double-layer integral low-pressure inner cylinder includes the upper half of the inner cylinder 4 including the steam inlet 1, the upper half of the left partition sleeve 14, the upper half of the right partition sleeve 15, the upper half of the outer and inner cylinder 5, and the upper half of the horizontal flange etc., the steam inlet 1 and the upper half of the inner and inner cylinder 4 are integrally cast, and the partition sleeve is c...

Embodiment 2

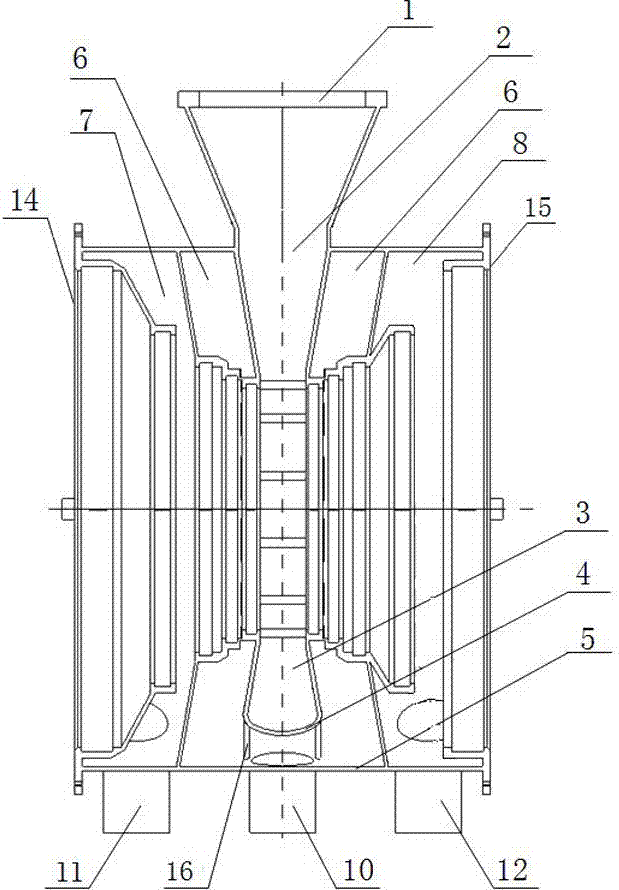

[0034] like image 3 , Figure 4 As shown, when the double-layer integral low-pressure inner cylinder needs to arrange three-stage regenerative steam extraction, it is asymmetrical along the center line of the inlet steam, and the left and right sides of the inner inner cylinder 4 itself form a low-pressure-extraction heat extraction cavity Chamber 6; the left section of the inner inner cylinder 4 and the left partition sleeve 14 are disconnected at the low-pressure secondary heat extraction port 11, and the right section of the inner inner cylinder 4 and the right partition sleeve 15 are at the 12 low-pressure three-regeneration heat extraction port Disconnected to form the low-pressure second and third extraction heat extraction chambers 7 and 8 respectively.

[0035] The upper half of the double-layer integral low-pressure inner cylinder includes the upper half of the inner cylinder 4 including the steam inlet 1, the upper half of the left partition sleeve 14, the upper ha...

Embodiment 3

[0040] like Figure 5 , Image 6 As shown, when the double-layer integral low-pressure inner cylinder needs to be arranged with four-stage regenerative steam extraction, it is asymmetrical along the steam inlet centerline, and the inner inner cylinder 4 is provided with low-pressure first and second regenerative steam extraction chambers along the steam inlet centerline The chamber partition plate 17 forms the low-pressure primary and secondary heat extraction chambers 6 and 7 respectively on the left and right sides of the inner cylinder 4 itself; The heat extraction port 12 is disconnected, and the right section of the inner cylinder 4 and the right partition sleeve 15 are disconnected at the low-pressure four-return heat extraction port 13 to form low-pressure three- and four-return heat extraction chambers 8 and 9 respectively. .

[0041] The upper half of the double-layer integral low-pressure inner cylinder includes the upper half of the inner cylinder 4 of the steam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com