Heating segmented temperature control tunnel type drying channel of burner

A technology of segmented temperature control and burner, which is applied in heating devices, lighting and heating equipment, drying and other directions, can solve the problems of increasing production costs, high power, and high power consumption of production plants, and achieves reduction of production costs, The effect of solving the problem of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

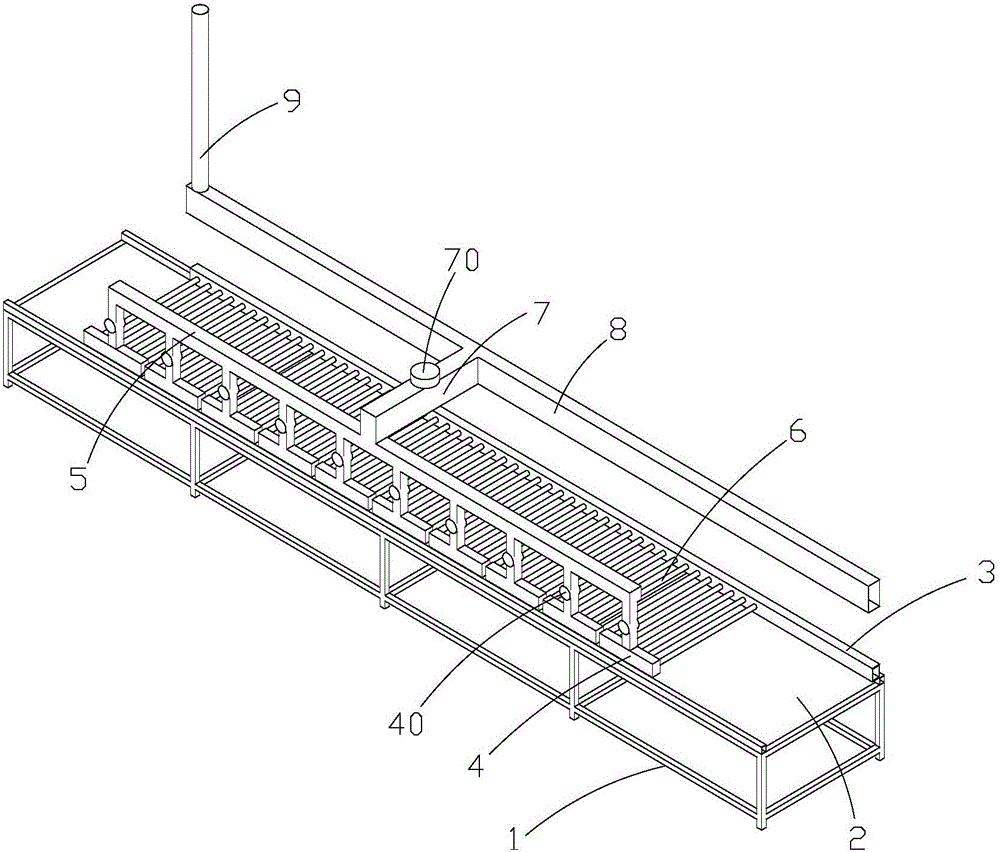

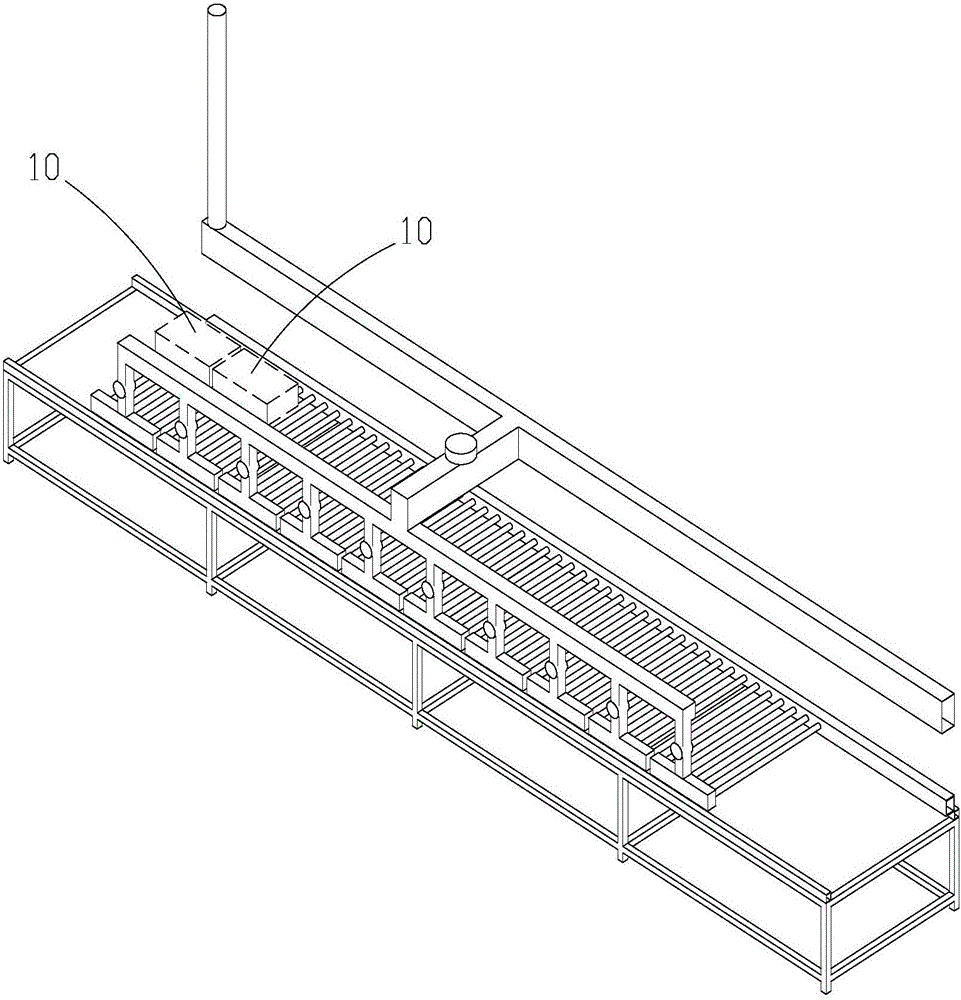

[0023] Such as figure 1 As shown, a burner heating segmental temperature-controlled tunnel-type drying tunnel, which includes a drying tunnel support frame 1, and a conveyor belt 2 for transporting color crystal glass is provided on the drying tunnel support frame 1. In the described A hot air pipe 3 is arranged on one side of the drying tunnel support frame 1, and several inverted "T"-shaped pipes 4 are arranged on the other side, and the top ends of the several inverted "T"-shaped pipes 4 are connected by a first connecting pipe 5. , and communicated, on the side below each group of inverted "T" tubes 4, several cooling air pipes 6 are connected to the hot air pipes 3, and on the first connecting pipe 5, the second connection The pipe 7 is connected with the hot air return pipe 8, and one end of the hot air pipe 3 is closed, and the other end is connected with the burner or the biomass pellet burner, and the heat source is provided by the burner or the biomass pellet burner....

Embodiment 2

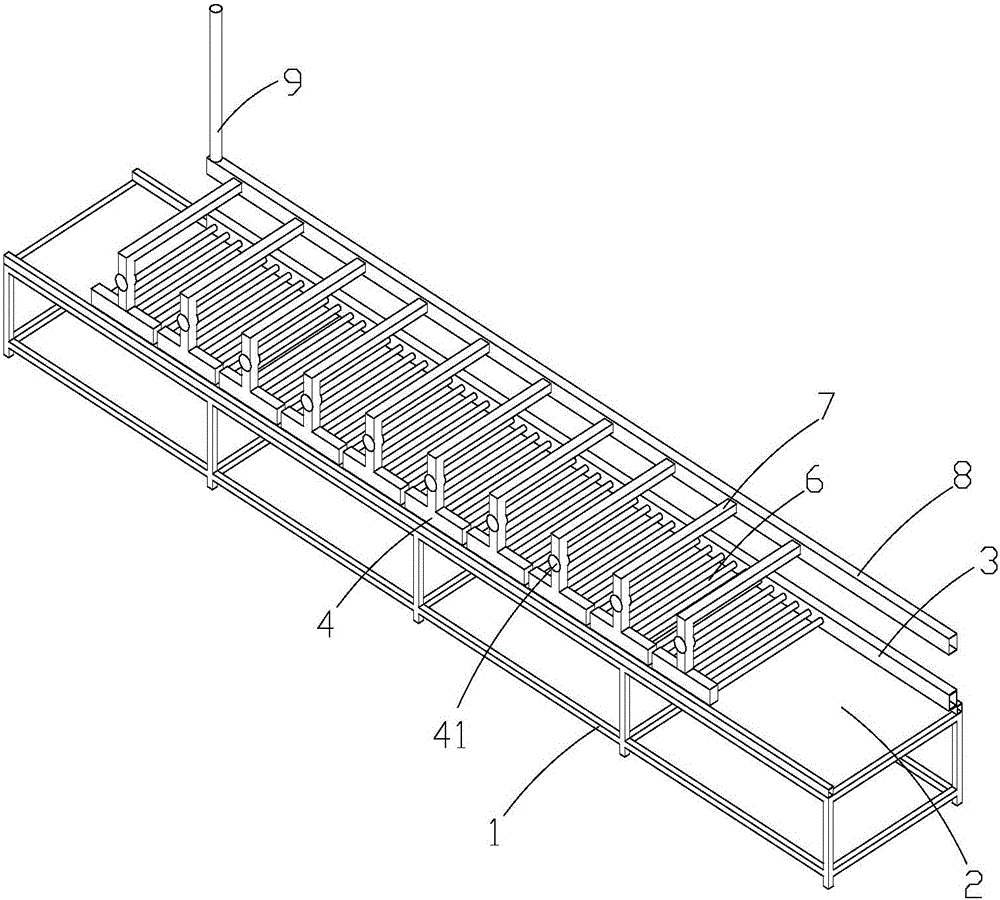

[0026] Such as figure 2 As shown, the top of each inverted “T” pipe 4 is connected to the heat return pipe through the second connecting pipe 7 , and each inverted “T” pipe 4 is provided with a temperature-controlled fan 41 .

[0027] Such as Figure 1-3 As shown, the present invention provides a heat source through a burner or a biological particle burner. In the case of providing a heat source, the present invention has two temperature control modes, and these two temperature control modes are as follows:

[0028] When the temperature control valve 40 controls the temperature: the heat source of the burner or the bio-particle burner will be evenly distributed on each heat dissipation air pipe 6, and the hot gas generated by the burner or the bio-particle burner will pass through the hot air pipe 3 to dissipate heat. Air pipe 6, inverted "T" pipe 4, first connecting pipe 5, second connecting pipe 7 and heat return air pipe 8 are then discharged from heat exhaust pipe 9, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com