White-light scanning interferometry measurement method and system

A technology of white light scanning and interferometry, applied in measuring devices, optical devices, instruments, etc., can solve problems such as large errors, and achieve wide application and strong anti-noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

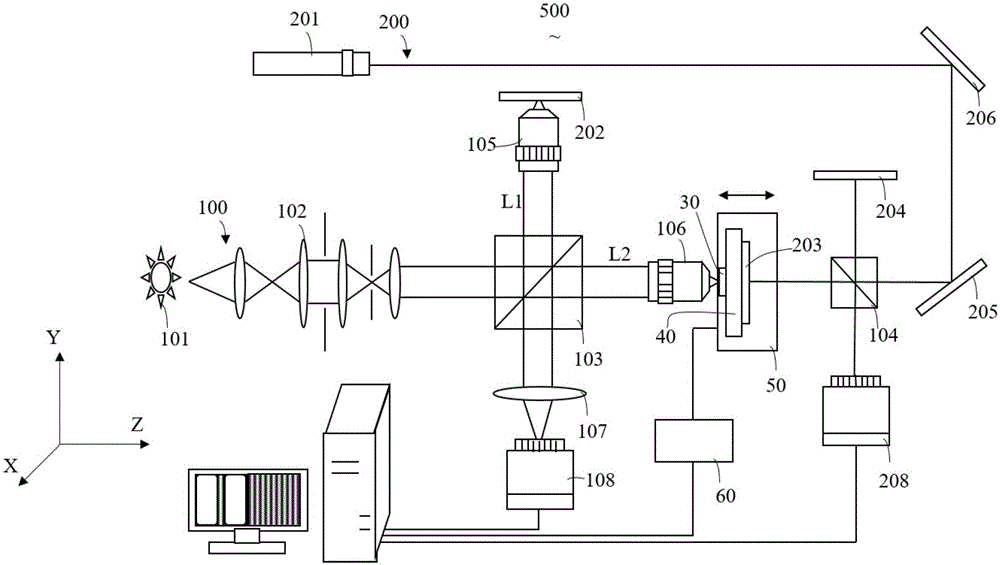

[0015] Such as figure 1 As shown, the white light scanning interferometry system 500 provided by the first embodiment of the present invention includes a white light scanning module 100, a calibration module 200, a fixed plate 40 for fixing the object to be measured 30, a piezoelectric ceramic micro-displacement platform 50, and a piezoelectric ceramic micro-displacement platform 50. Electroceramic controller 60.

[0016] Wherein said white light scanning module 100 comprises: a white light source 101, a Koehler illumination system 102, a first beam splitter 103 and a second beam splitter 104, a first microscope objective lens 105 and a second microscope An objective lens 106 , an imaging lens 107 , and a first monochromatic black and white image sensor 108 .

[0017] Wherein the calibration module 200 includes a laser 201; a first plane mirror 202, a second plane mirror 203, a third plane mirror 204, a fourth plane mirror 205, a fifth plane mirror 206, a second single color...

no. 2 example

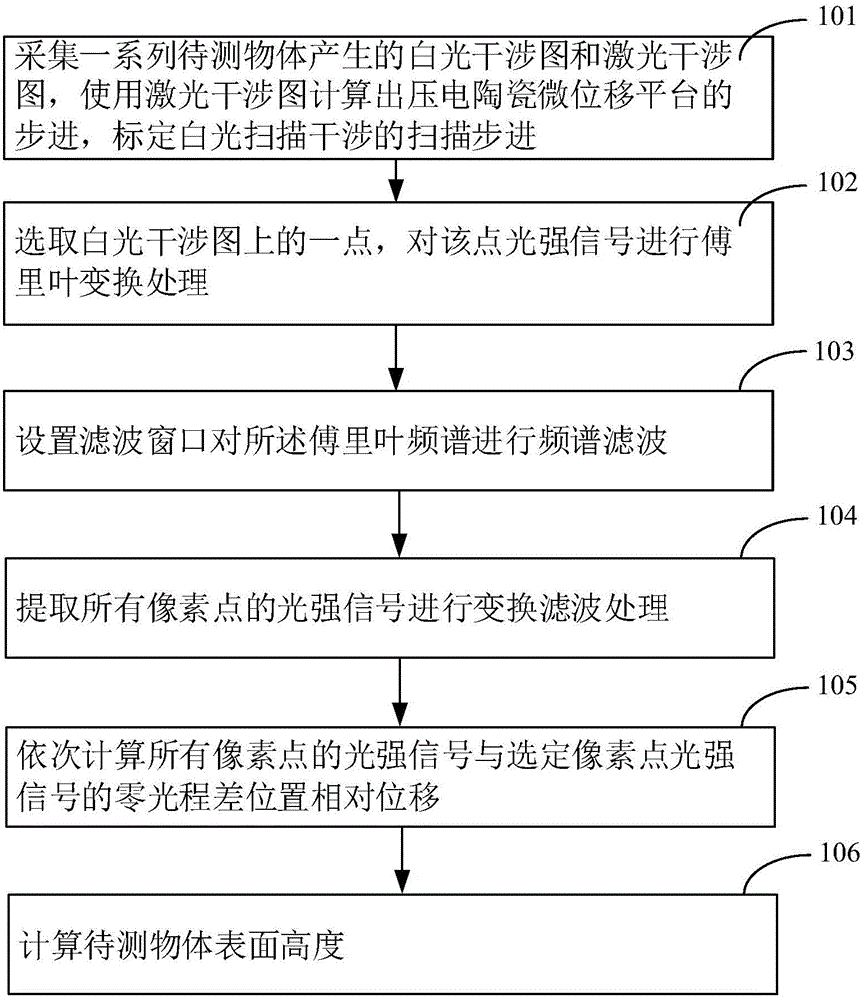

[0034] Please refer to figure 2 , the white light scanning interferometry method based on generalized correlation time delay estimation will be further described in conjunction with the accompanying drawings and embodiments in conjunction with this embodiment. In this method, the white light scanning interferometry system 500 described in the first embodiment is used to perform The measurement includes the following steps S101-S106.

[0035] Step S101, collect a series of white light interferograms and laser interferograms generated by the object to be measured, use the laser interferogram to calculate the step of the piezoelectric ceramic micro-displacement platform 50, and calibrate the scanning step of the white light scanning interference:

[0036] During specific measurement, a computer is used to drive the first monochrome black-and-white image sensor 108 and the second monochrome black-and-white image sensor 208 to simultaneously collect a series of white light interfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com