Method for measuring characteristics of sliding bearing film

A technology for sliding bearings and oil film characteristics, which is applied in the field of measurement of oil film characteristics of sliding bearings, can solve the problems of solving oil film characteristics, the difficulty of sliding bearing oil film characteristic parameters, and the impossibility of direct measurement, so as to save measurement costs and improve efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

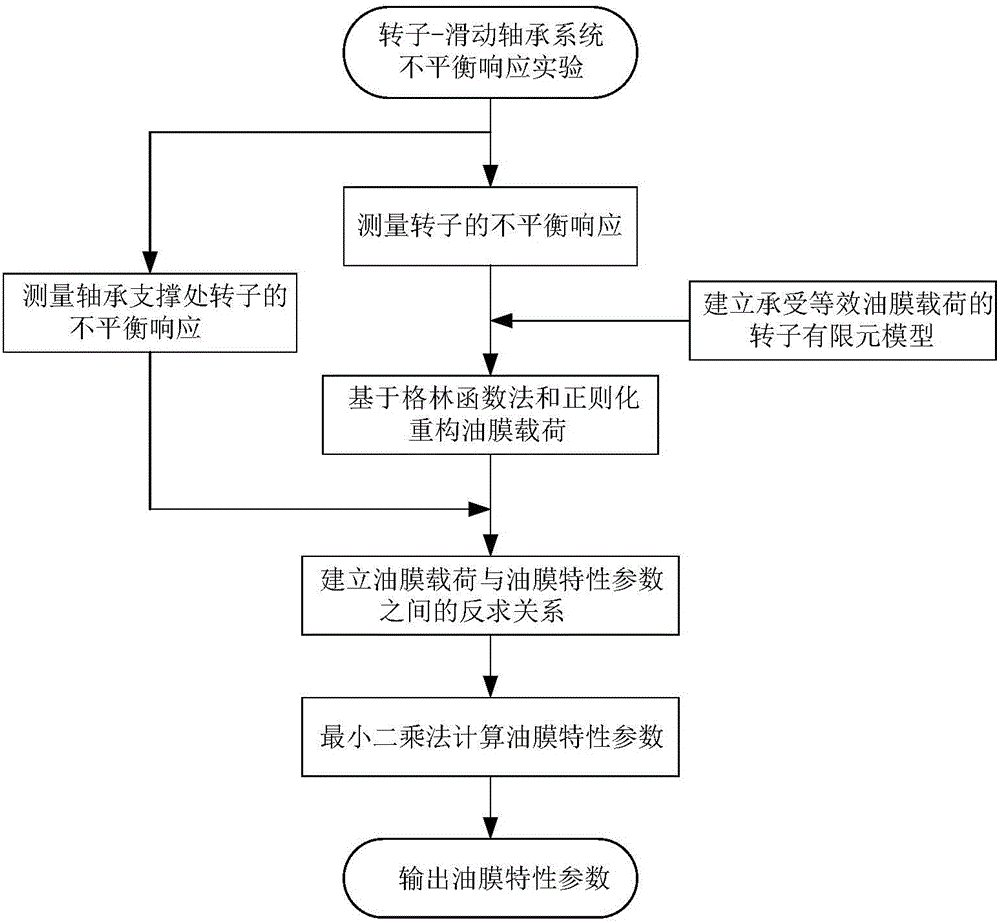

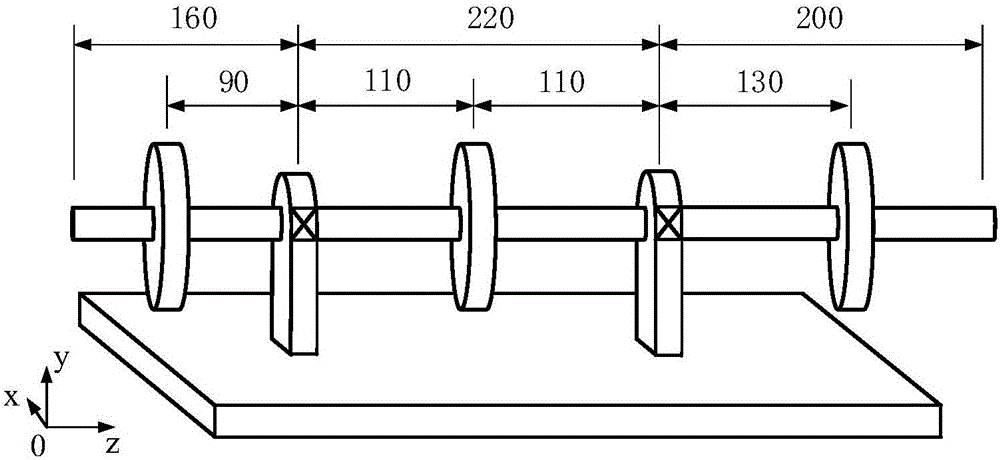

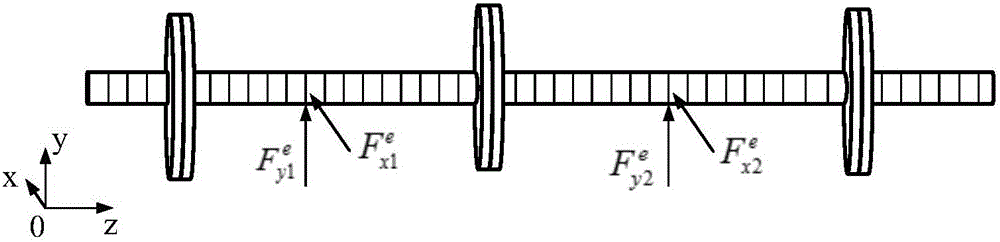

[0036] Attached below figure 1 -5. Taking the identification of the characteristic parameters of the oil film of the sliding bearing by using the response of the rotor unbalance experiment as an example, the specific implementation manner of the present invention will be described in detail.

[0037] During the high-speed operation of the rotor, the characteristic parameters of the oil film of the sliding bearing are usually difficult to obtain through experiments or the cost of obtaining is too high, while the measurement of the unbalance response of the rotor is relatively easy. Therefore, through the finite element modeling of the rotor, the support effect of the oil film of the sliding bearing on the rotor can be approximately equivalent to two radial equivalent load constraints. Then the inverse relationship between the equivalent oil film load and the oil film characteristic parameters is established, and the stiffness and damping characteristic parameters of the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com