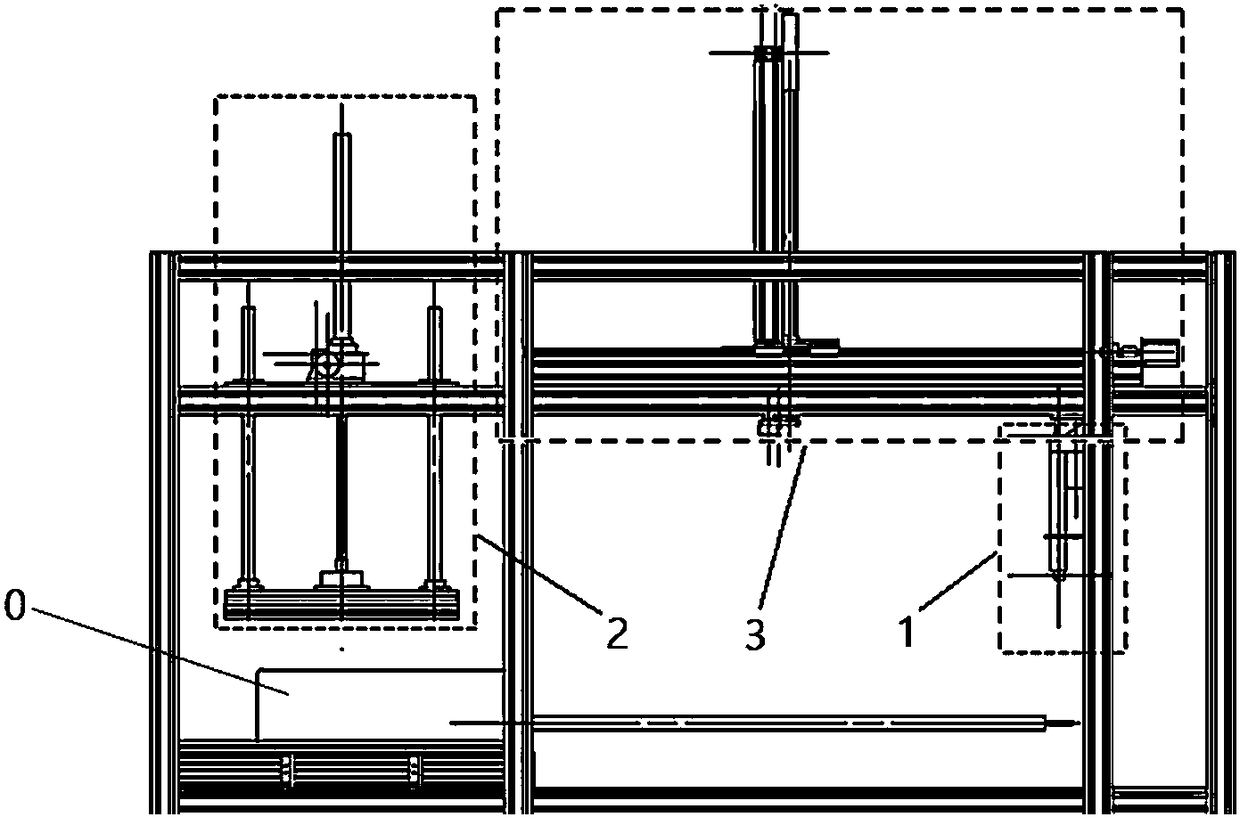

Automatic testing method and system for radial mechanical properties of draft beer barrel spear seat

A test method and technology of mechanical properties, applied in the field of automatic test method and system of radial mechanical properties of beer barrel spear seat, to achieve the effect of reliable measurement method, avoiding loading error and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

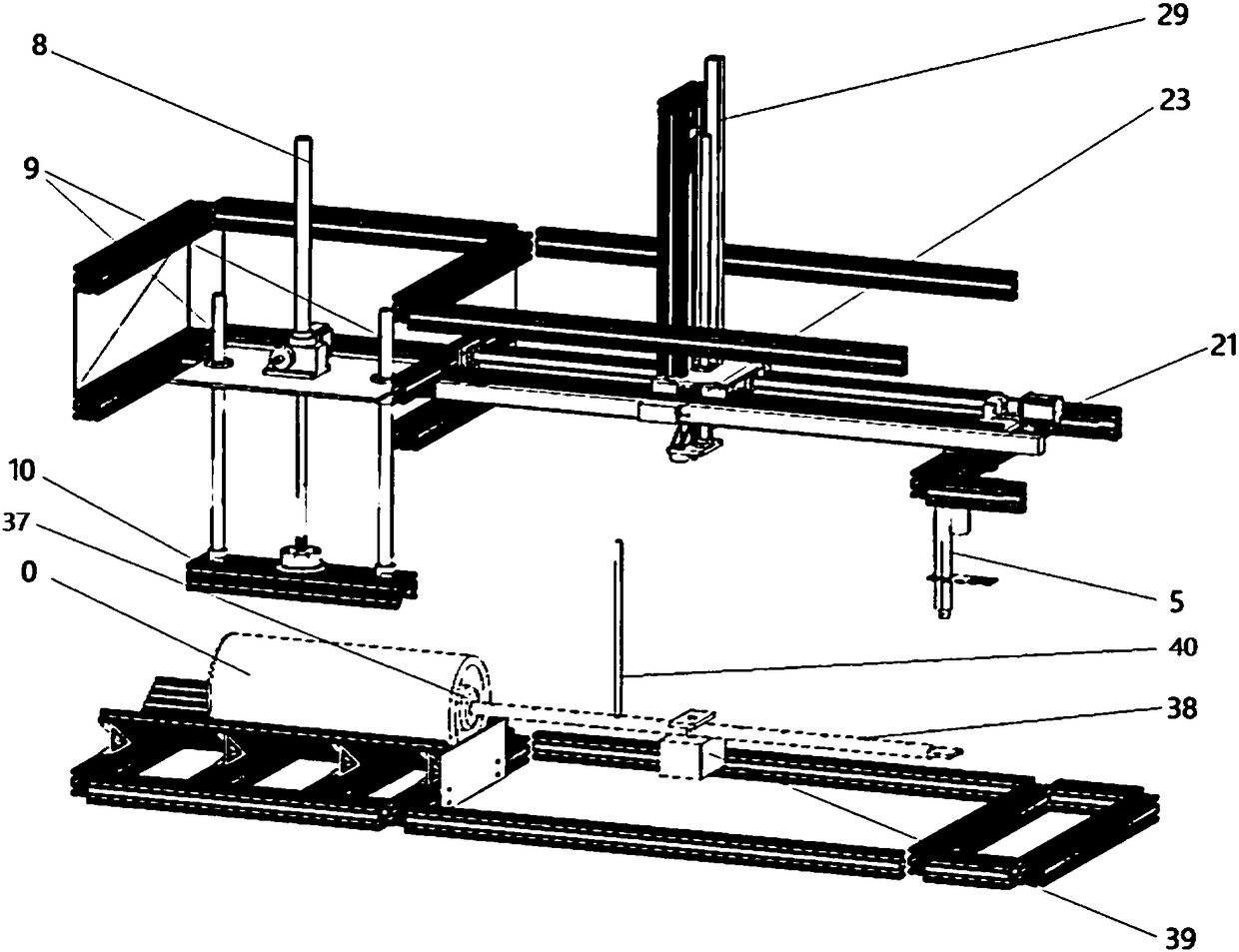

[0064] like Figure 10 As shown, the process of utilizing the device in Embodiment 1 to carry out dynamic load automatic loading is as follows:

[0065] S1, the clamping of the barrel. The calculation unit sends a signal to the driving device to control the driving motor of the V-shaped clamping and fixing mechanism of the draft beer keg to realize the clamping of the keg. At the same time, the spoke-type force sensor at the bottom of the V-shaped clamping and fixing mechanism transmits the detected pressure value to the computing unit in real time through the multi-function data acquisition card. When the clamping force reaches the set pressure threshold, the clamping stops and continues.

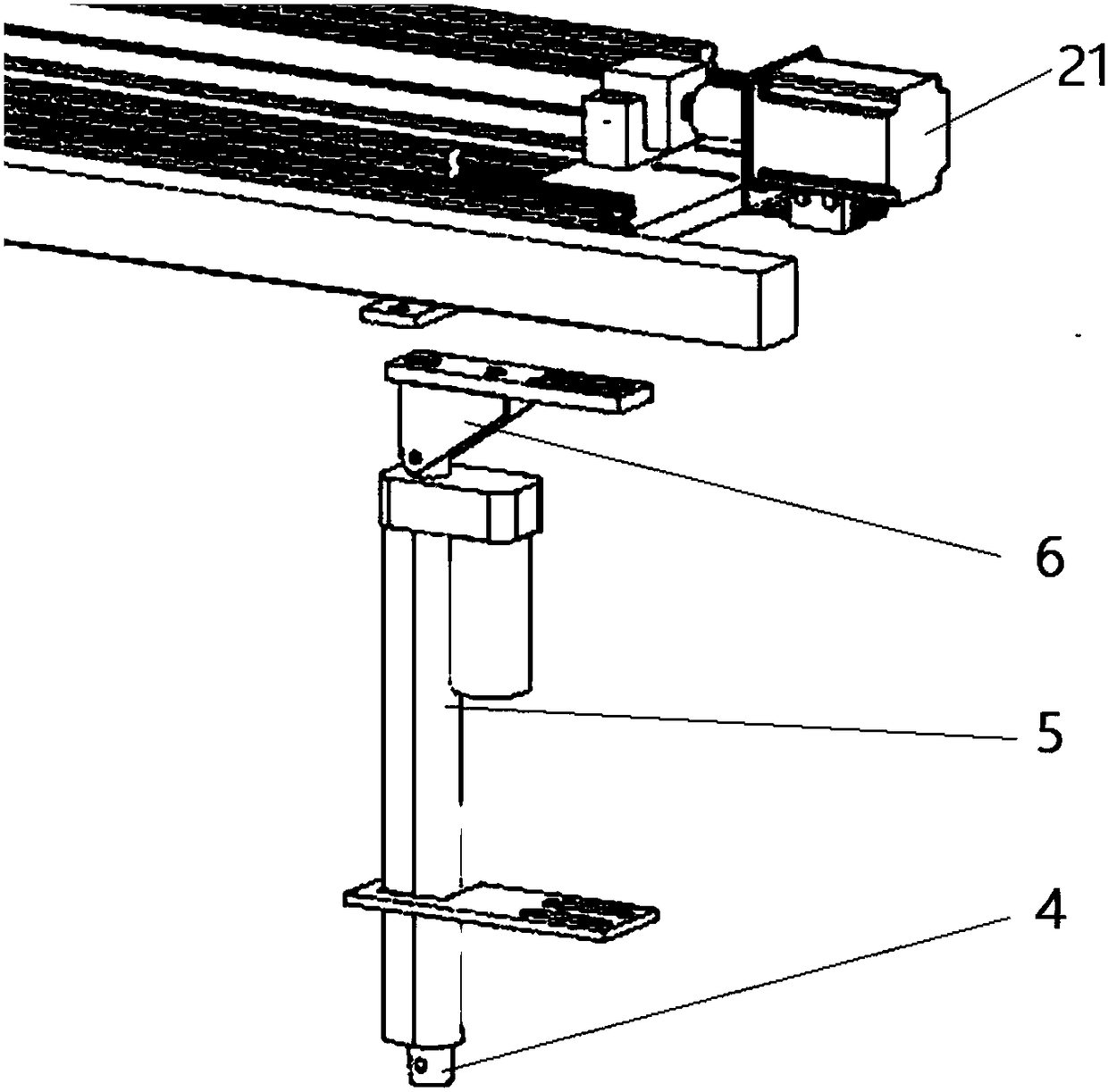

[0066] S2. Determine the loading position of the dynamic load. According to the actual measurement requirements, adjust the installation position of the dynamic load loading guide rod on the radial loading beam.

[0067] S3. Adsorption of weights. The calculation unit controls the late...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com