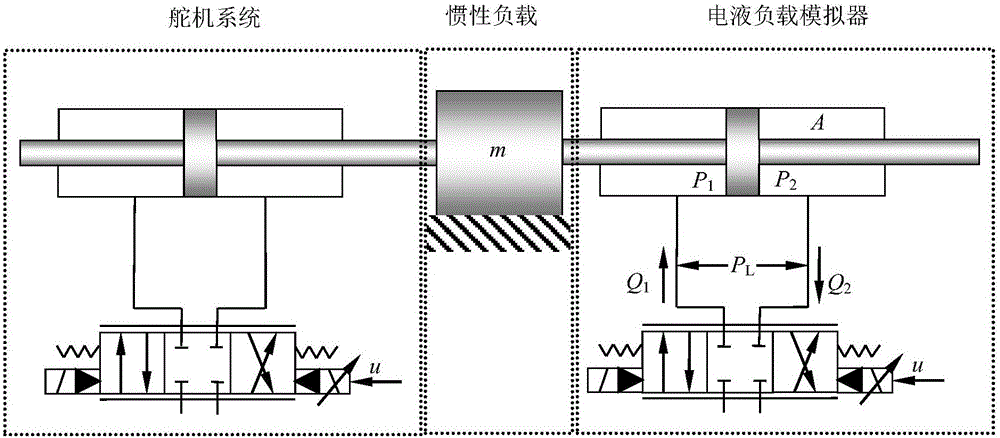

Method for self-adjustment error symbol integral robust control of electro-hydraulic torque servo system

A servo system and error symbol technology, which is applied in the field of self-adjusting error symbol integral robust control of electro-hydraulic torque servo system, and can solve the problems of controller discontinuity, model uncertainty, engineering limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

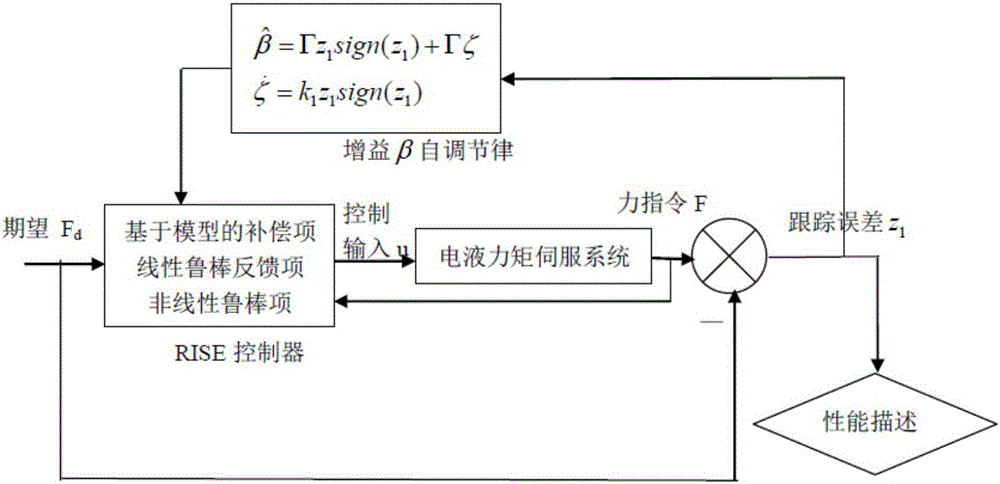

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

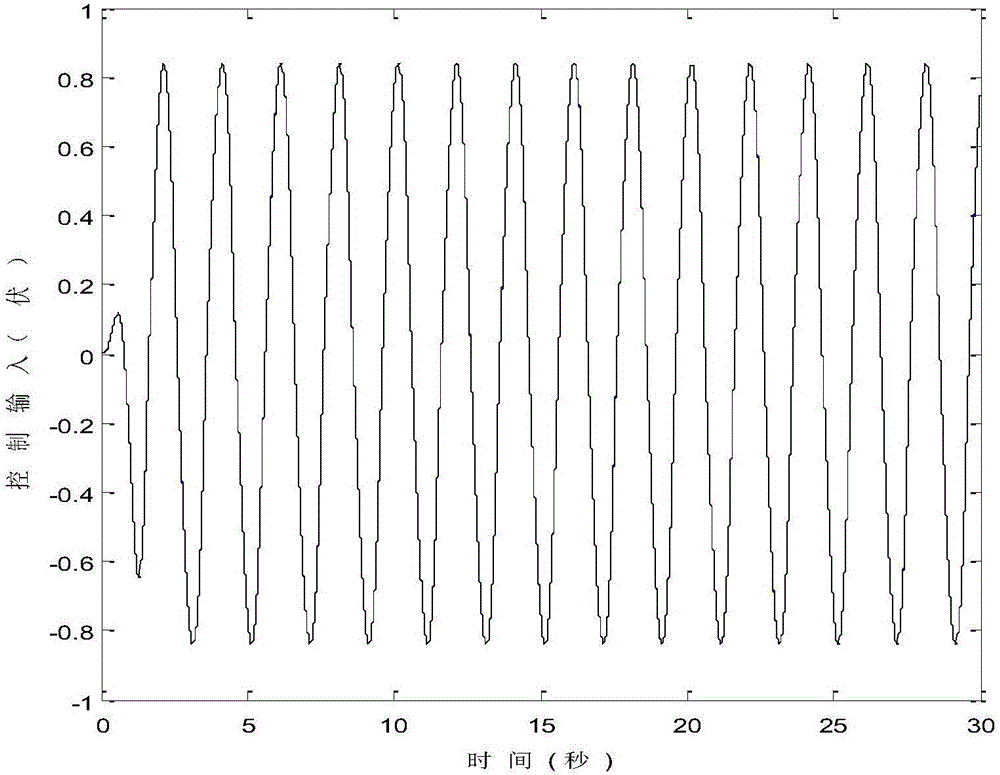

[0168]In order to assess the performance of the designed controller, the following parameters are taken in the simulation to model the electro-hydraulic torque servo system:

[0169] A=2×10 -4 m 3 / rad,V 01 =V 02 =1.7×10 -4 m 3 B=80N·m·s / rad,β e =2×10 8 Pa,C t =9×10 -12 m 5 / (N·s), P s =21×10 6 Pa, P r =0Pa, J=0.32kg·m 2 ,A f =80Nm,

[0170] The designed controller parameters are selected as: k 1 =900,k r =0.001, The self-regulating law gain Γ=5. The time-varying external disturbance of the system is selected as d=200sint, and the trajectory is The force command that the system expects to track is a curve

[0171] The effect of the control law:

[0172] image 3 It is a curve diagram of controller u changing with time in the embodiment, and the input voltage of the controller satisfies the input range of -10V~+10V, which is in line with practical application.

[0173] Figure 4 is the system disturbance as A plot of the estimated value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com