A railway vehicle bottom equipment rubber supporting base support reaction force acquiring method

A technology for off-board equipment and railway vehicles, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as long solution time, shortage, and many dynamic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

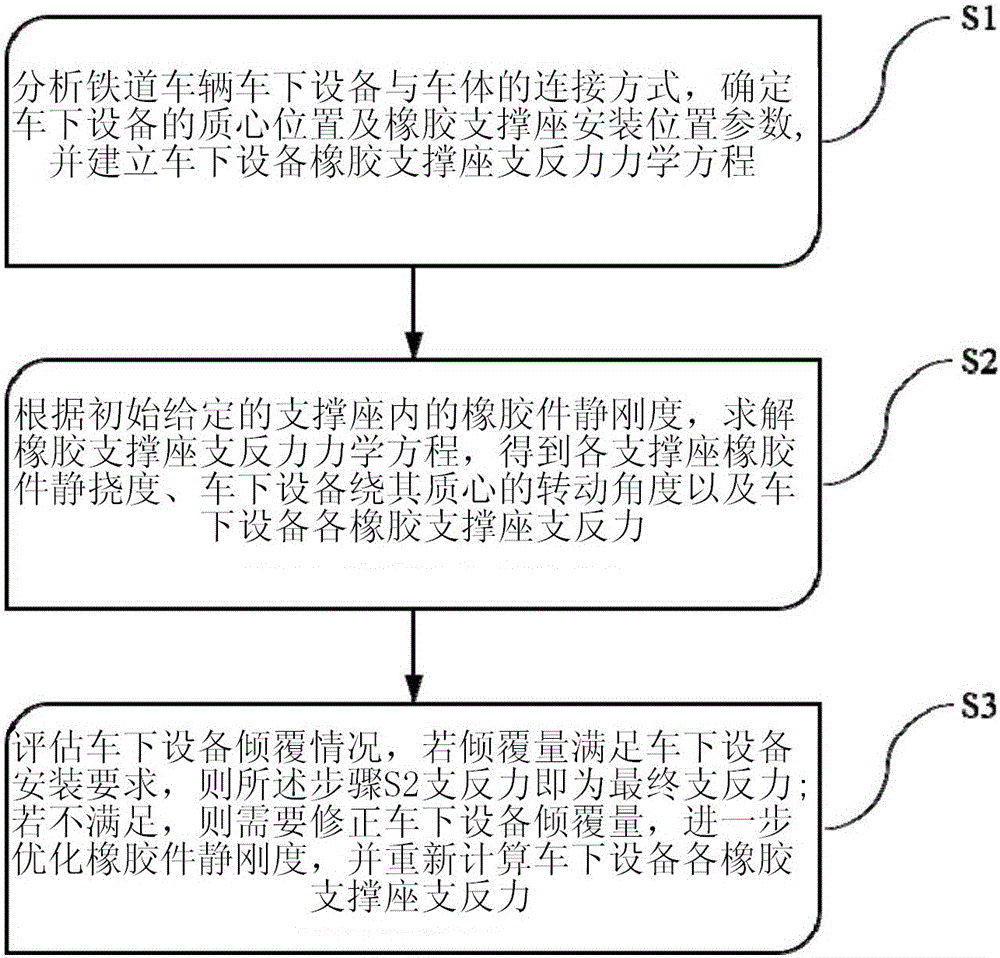

[0050] Such as figure 1 As shown, a method for obtaining the reaction force of the rubber support seat of the equipment under the railway vehicle, the specific implementation steps are as follows:

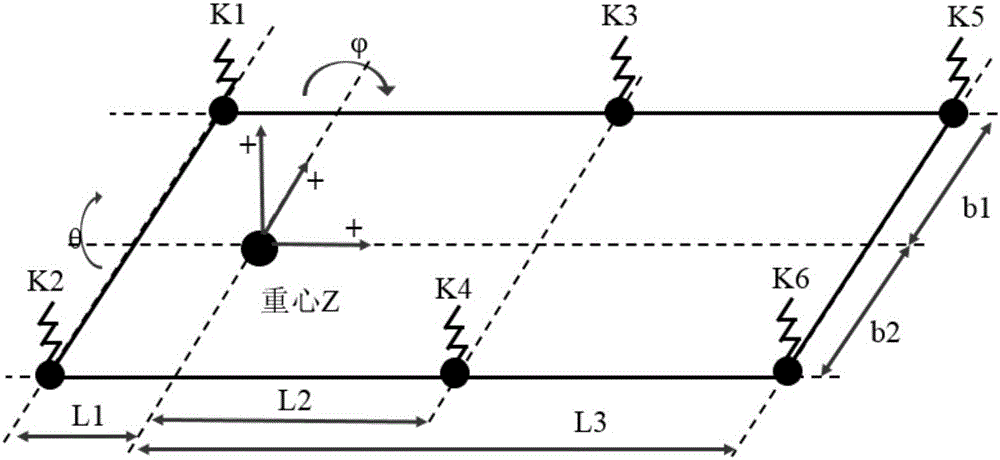

[0051] S1: Determine the position of the center of mass of the under-vehicle equipment and the installation position parameters of the rubber support seat, and establish the mechanical equation of the reaction force of the rubber support seat of the under-vehicle equipment.

[0052] S2: According to the static stiffness of the rubber parts in the initially given support seat, solve the mechanical equation of the reaction force of the rubber support seat, and obtain the static deflection of the rubber parts of each support seat, the rotation angle of the equipment under the vehicle around its center of mass, and the rubber components of the equipment under the vehicle. The support seat supports the reaction force.

[0053]S3: Evaluate the overturning of the under-vehicle equipment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com