Linear heat fire detector

A fire detector and line-type technology, applied in the field of fire detectors, can solve the problems of delayed alarm and fire fighting and rescue timing, lower cost performance of engineering applications, and limited protection radius, so as to improve early fire response capability and alarm accuracy, expand The effect of reducing the cost of product application sites and engineering equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0035] In view of the shortcomings of the current linear temperature-sensitive fire detectors, several relay units can be integrated on the temperature-sensitive cables of the online temperature-sensitive fire detectors to form a low-cost and strong anti-electromagnetic interference and The multi-combination linear heat-sensing fire detector with early fire response ability can solve some existing problems.

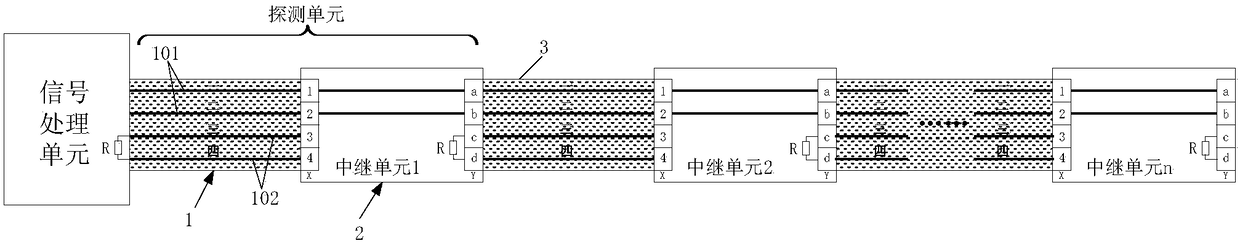

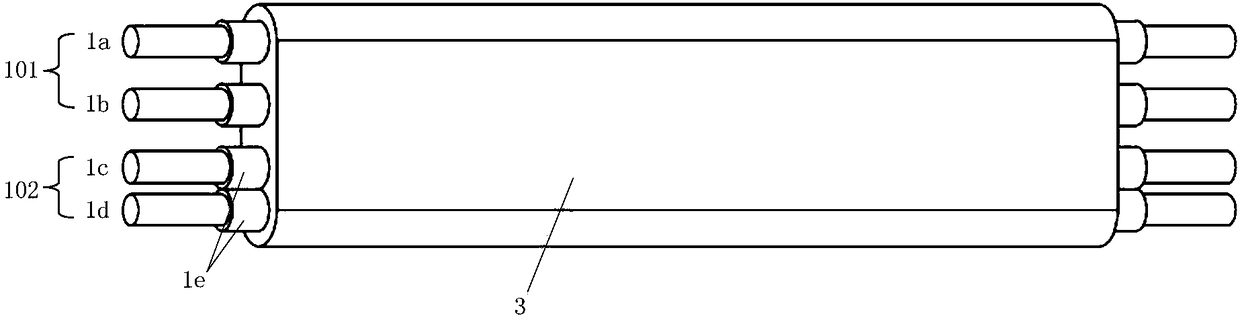

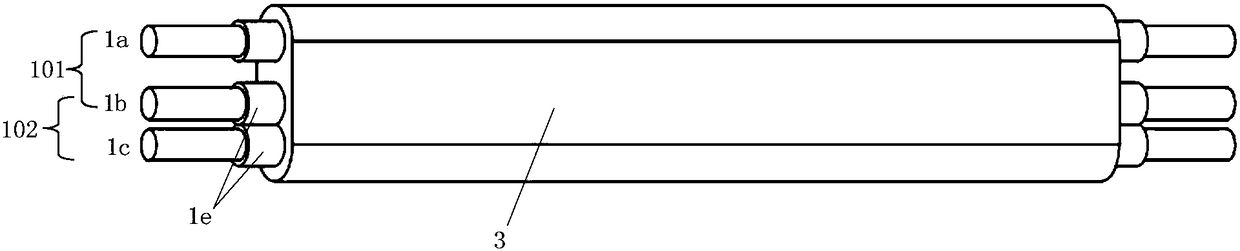

[0036] Such as figure 1 As shown, the linear temperature-sensitive fire detector provided by the present invention includes a signal processing unit and sensitive components connected with the signal processing unit; figure 1 In , the components on the right side of the signal processing unit are all sensitive components;

[0037] Sensitive components are usually composed of multi-level detection units cascaded; in the shortest case, sensitive components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com