Detection panel and manufacturing method thereof, and photoelectric detection device

A manufacturing method and panel technology, applied in the direction of measuring devices, radiation control devices, circuits, etc., can solve the problems of reducing pixel sensitivity and loss, and achieve the effect of improving the sensitivity of the photoelectric effect and the level of pixel sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

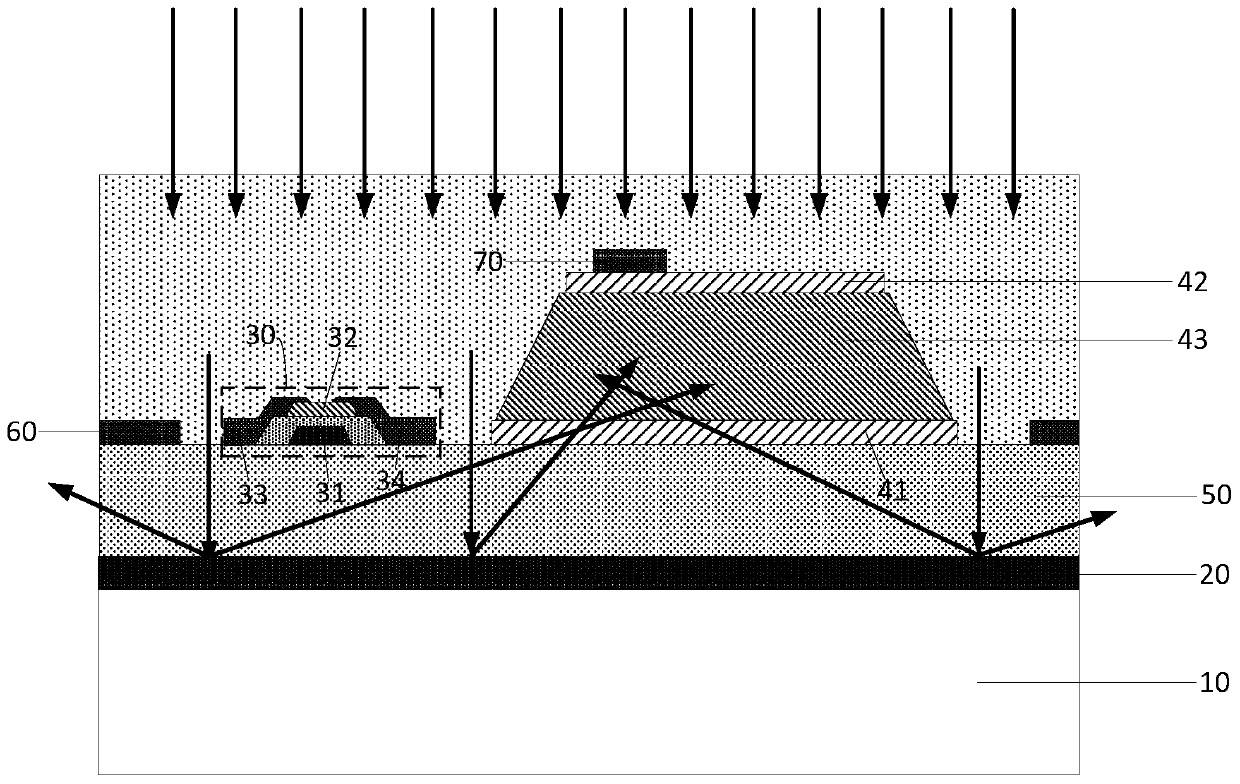

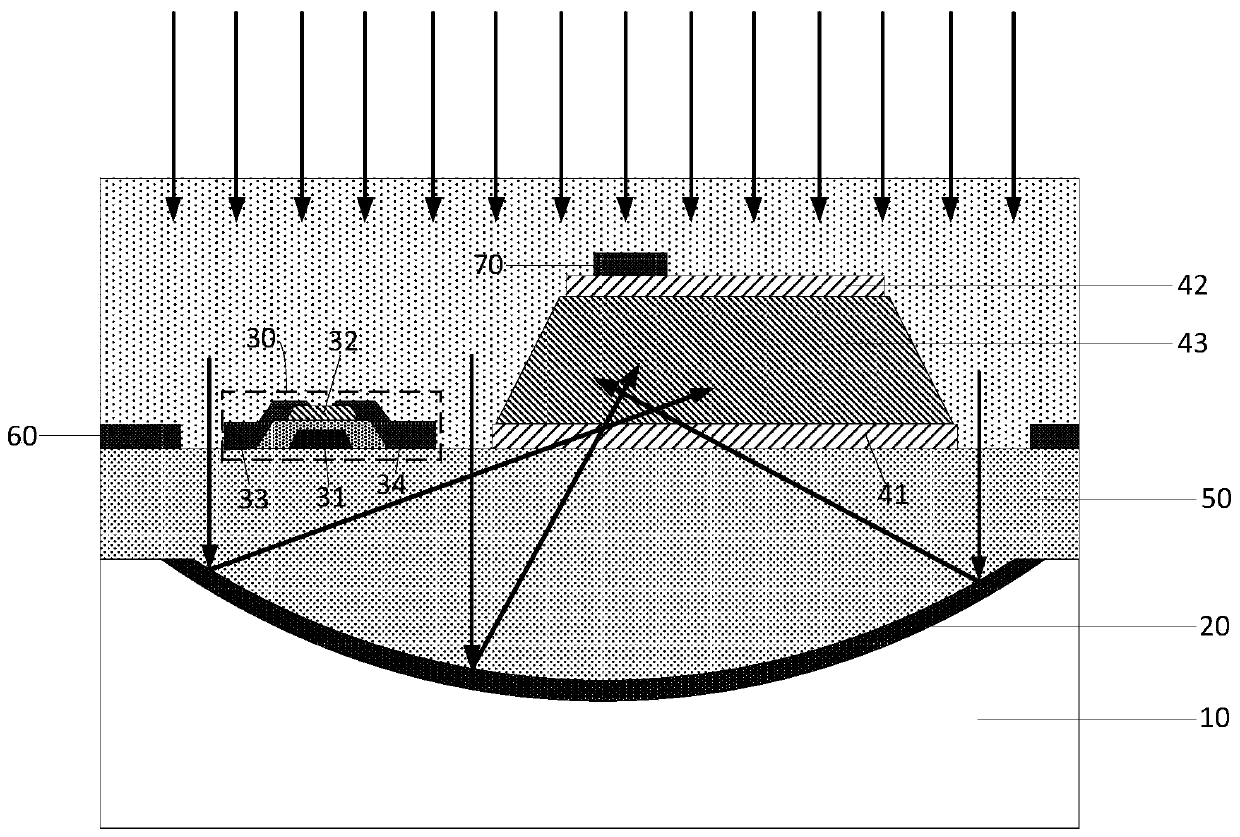

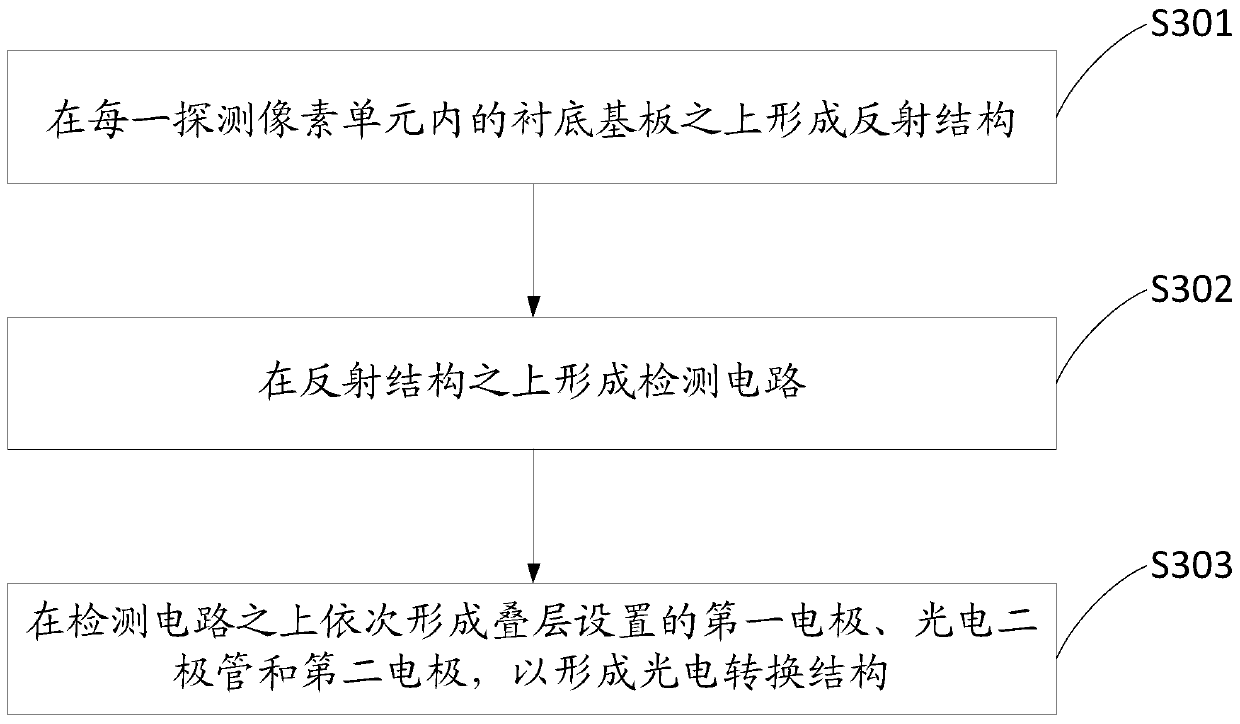

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the specific implementations of the detection panel, its manufacturing method and detection device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0034] The thickness and shape of each layer of film in the drawings do not reflect the real scale of the detection panel, and the purpose is only to illustrate the content of the present invention.

[0035] At present, improving the visible light utilization rate of FPXD pixels is an important technical direction to improve image signal-to-noise ratio and reduce X-ray radiation dose. The current trend of mainstream pixel design improvement mainly revolves around increasing the filling rate of photodiodes in pixels to further increase the photosensitive area. But in fact, under the premise that the filling rate of the photodiode in the pixel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com