Intelligent type high voltage transformer

A high-voltage transformer and intelligent technology, applied in the field of high-voltage power, can solve problems such as the application and promotion of high-voltage transformers, achieve excellent anti-loosening effects, reduce vibration, and ensure stable and reliable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

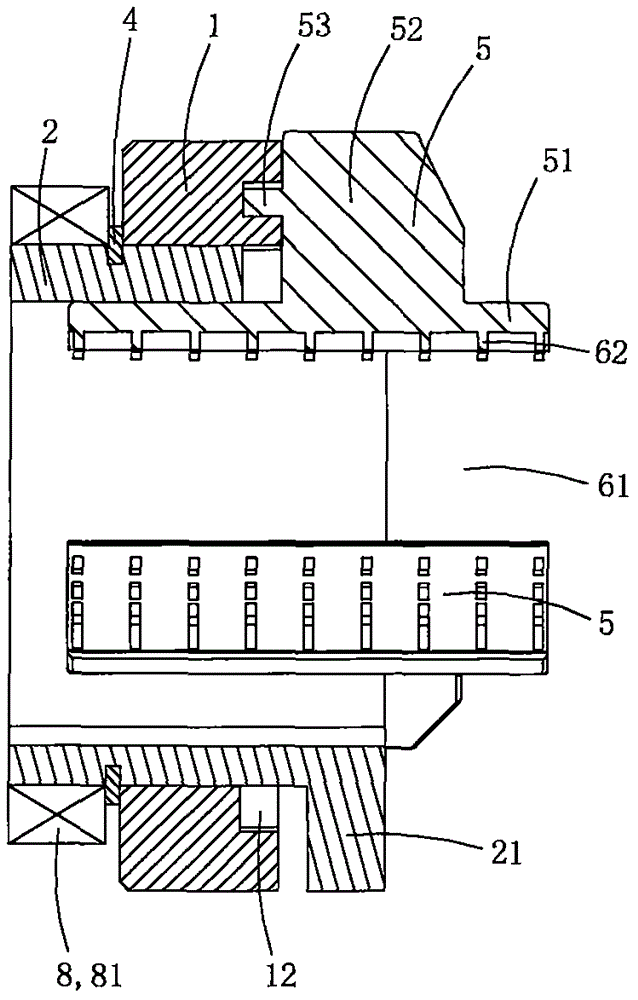

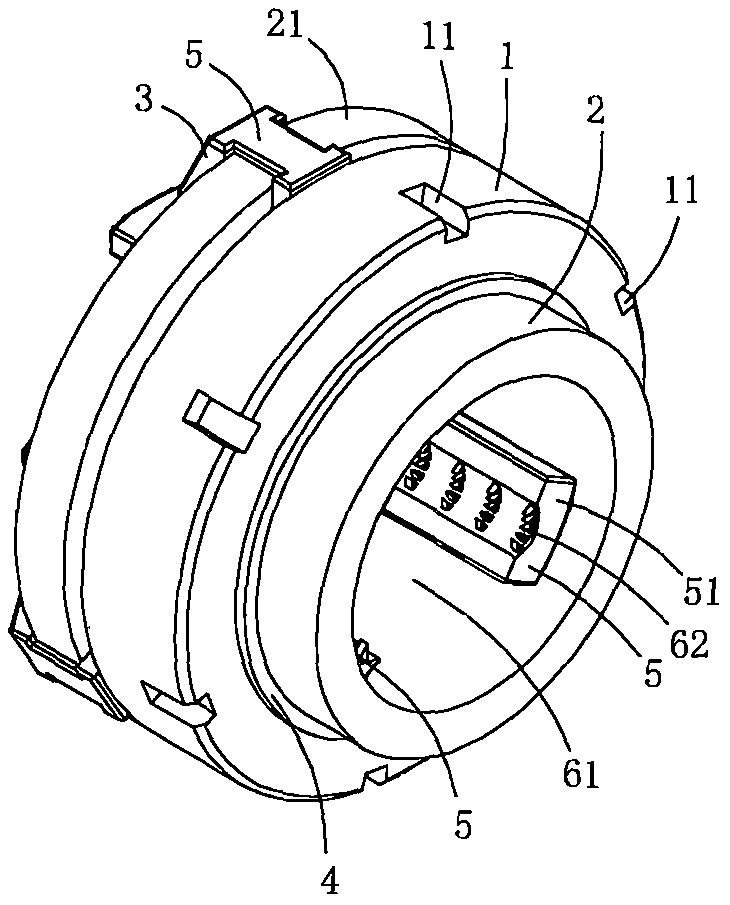

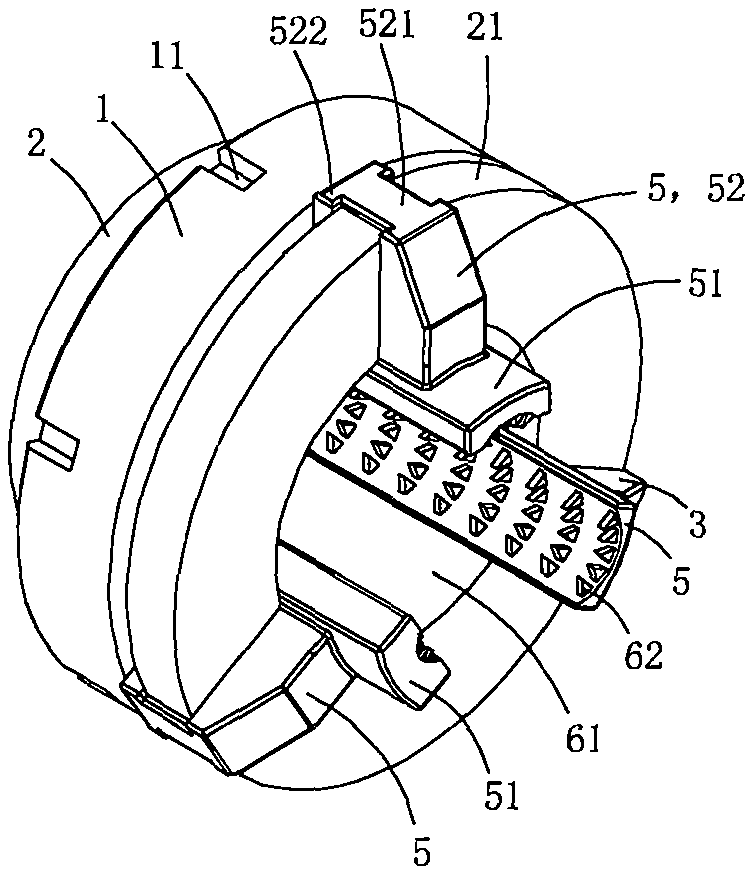

[0018] This embodiment is a high voltage transformer, see Figure 1 to Figure 9 As shown, it includes a pressure ring 1 , a core tube 2 , a set of pressure claw assemblies 3 , a voltage transformer 8 and an axial retaining ring 4 .

[0019] The outer peripheral wall of the core tube 2 is provided with an outwardly convex stopper 21 and a concave annular groove 22, and three radial guide holes 23 are evenly distributed along the circumferential direction on the core tube wall; in this embodiment, each radial direction The guide hole runs through the wall of the core tube in the radial direction of the core tube. The axial retaining ring is arranged in the annular groove of the core tube.

[0020] Each radial guide hole 23 includes a guide slide hole 231 and an anti-slip hole 232 arranged in sequence along the axial direction of the core tube; The guide sliding holes are connected; the radial cross-sectional shape of each radial guide hole is T-shaped; each radial guide hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com