Electronic component device production method and electronic component sealing sheet

A technology for electronic components and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electronic equipment, etc., can solve problems such as inability to position and align, and achieve the effect of suppressing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

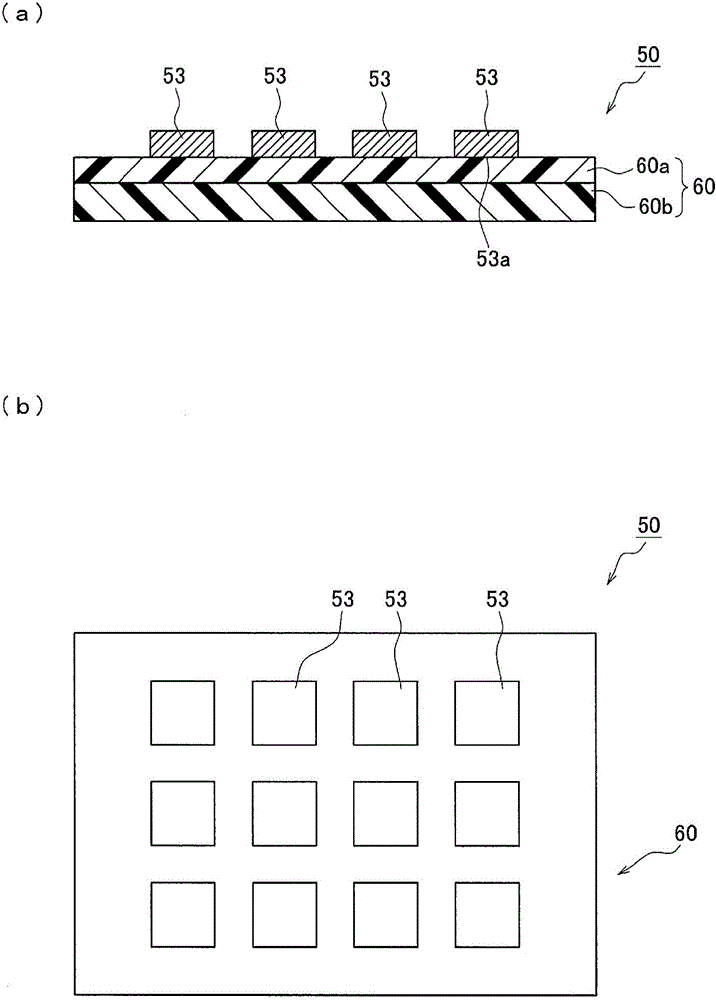

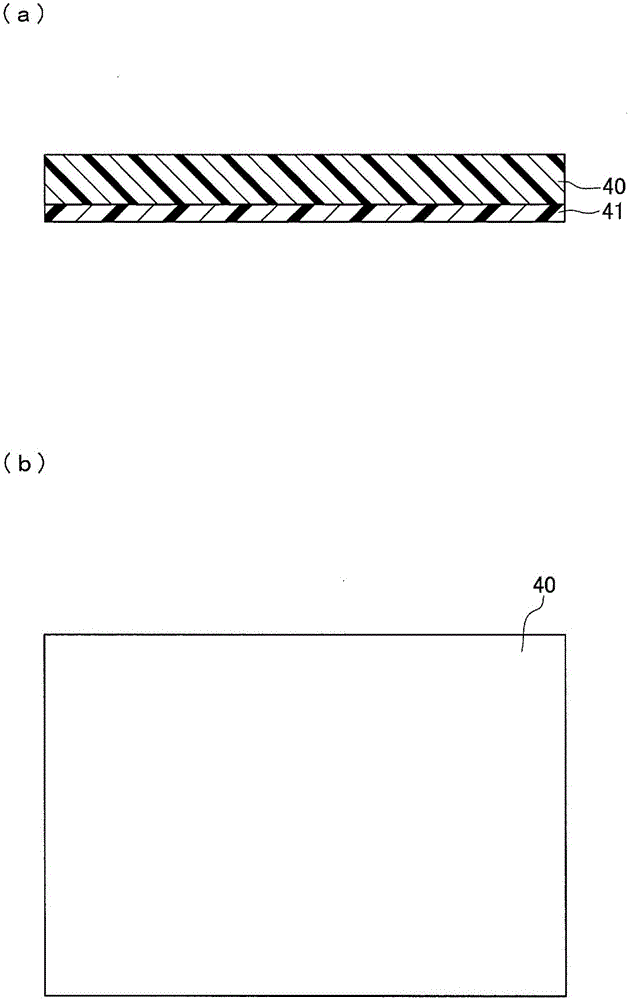

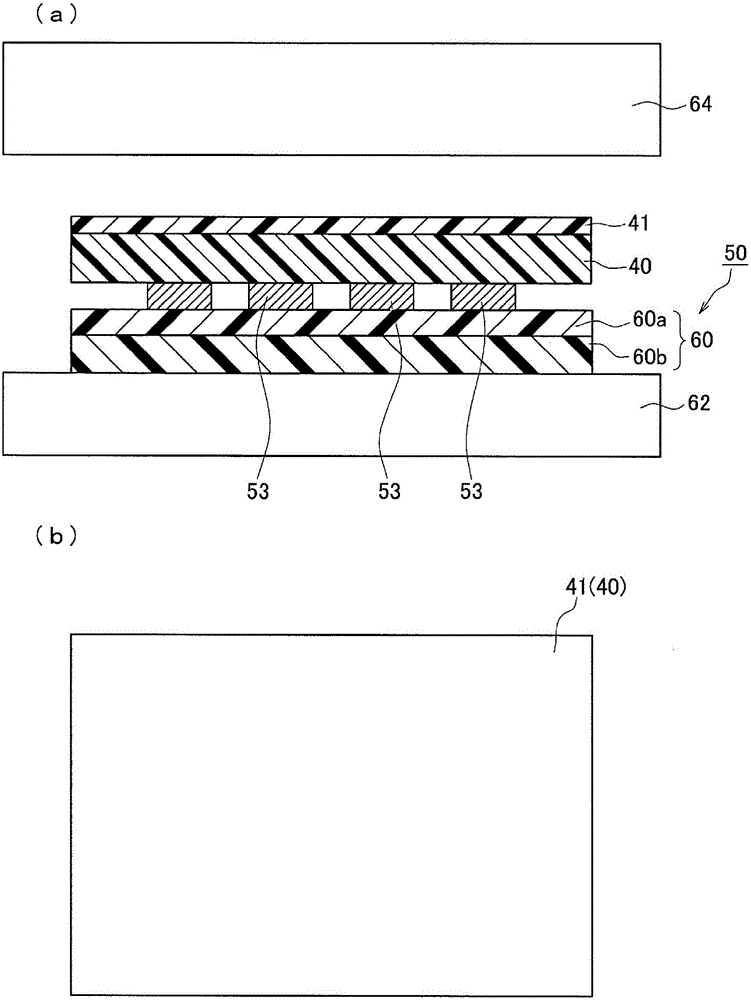

[0218] According to the compounding ratio described in Table 1, compound the ingredients, and use a roll mill to heat the mixture under reduced pressure (0.01kg / cm2) at 60-120°C for 10 minutes. 2 ) were melt-kneaded to prepare a kneaded product. Next, the obtained kneaded product was arranged so as to be sandwiched between two 50 μm protective films (manufactured by Mitsubishi Plastics Corporation: trade name "MRF"), and the kneaded product was formed into a sheet by a flat press method to produce A sheet for sealing with a thickness of 200 μm.

Embodiment 4

[0220] According to the compounding ratio described in Table 1, the epoxy resin, phenolic resin, thermoplastic resin and inorganic filler were added into the organic solvent MEK (methyl ethyl ketone) in a manner that the solid content concentration was 95%, and stirred. Stirring was performed at 800 rpm for 5 minutes using a planetary mixer (manufactured by Thinky Co., Ltd.). Thereafter, according to the compounding ratio described in Table 1, carbon black and a curing accelerator were further compounded, and MEK was added so that the solid content concentration became 90%, and further stirred at 800 rpm for 3 minutes to obtain a coating liquid.

[0221] Thereafter, the coating solution was coated on a silicone release-treated polyethylene terephthalate film having a thickness of 50 μm, and dried at 120° C. for 3 minutes to prepare a resin sheet with a thickness of 100 μm. Furthermore, the produced resin sheet was bonded together at 90 degreeC with the roll laminator, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com