Multifunctional high-efficient peeling machine

A peeling machine and multi-functional technology, which is applied in the field of peanut, melon seed peeling processing machinery and garlic, can solve the problems of peeling affected by the dry humidity of the product, complex equipment structure, and low work efficiency, and achieve a wide range of peeling objects and low energy consumption , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The concrete implementation of the present invention is illustrated below in conjunction with accompanying drawing:

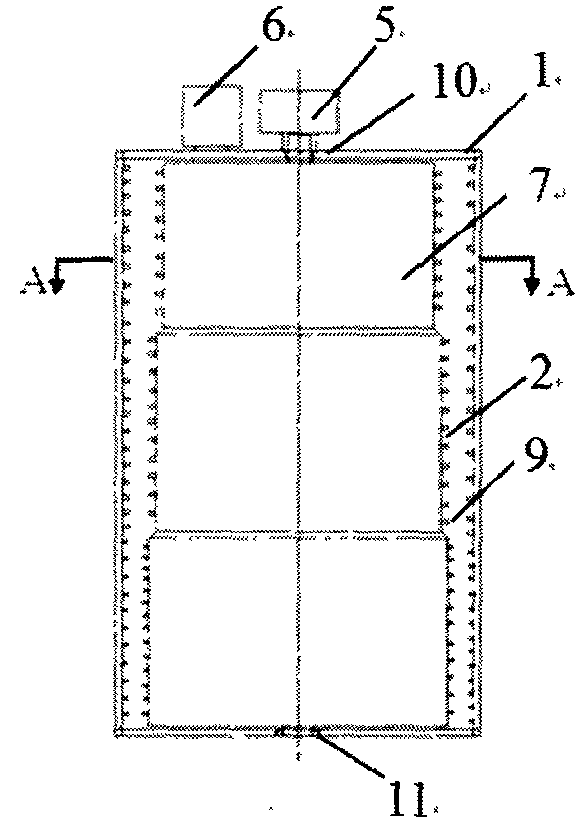

[0022] A multifunctional high-efficiency peeling machine includes a housing 1, a peeling rotor 2, a control device 6, a driving device 5, a material inlet 3, and a material outlet 4.

[0023] The control device 6 and the driving device 5 are installed on the top of the equipment, the control device 6 adopts single-chip centralized control, and the driving device 5 and the peeling rotor 2 are connected by keys.

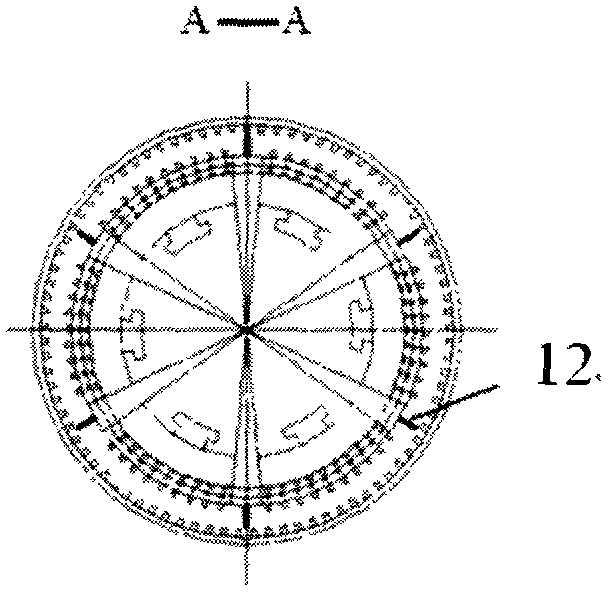

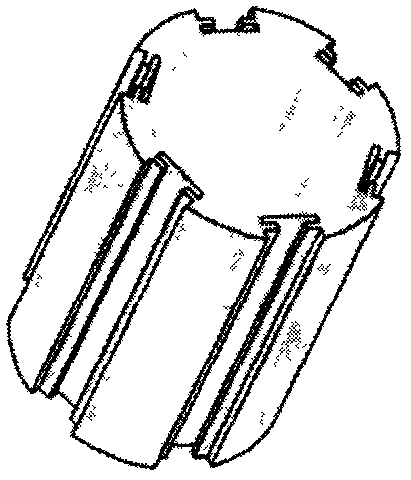

[0024] The peeling finger 9 is installed on the peeling blade 8 and the inner wall of the cylinder through special tooling, the peeling blade 8 is installed on the rotor shaft 7 through a T-shaped structure, and a partition 12 is installed between two peeling blades 8, so that each peeling blade 8 Each has its own independent dynamic working sector, and each independent dynamic working chamber is divided into three cavities of different sizes in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com