Filter stick coating device, system and coating method

A technology of filter rods and power devices, which is applied in the field of filter rod gluing devices, and can solve problems such as inability to complete filter rod roll forming, filter rod opening bursting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

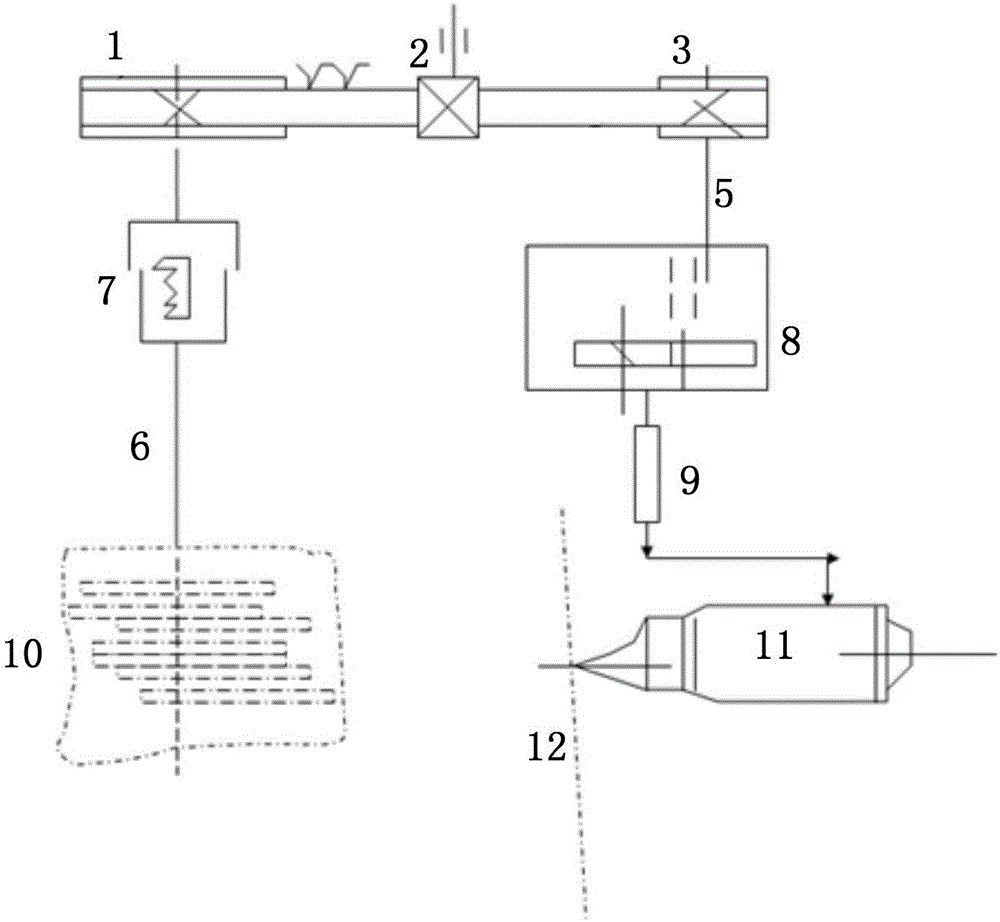

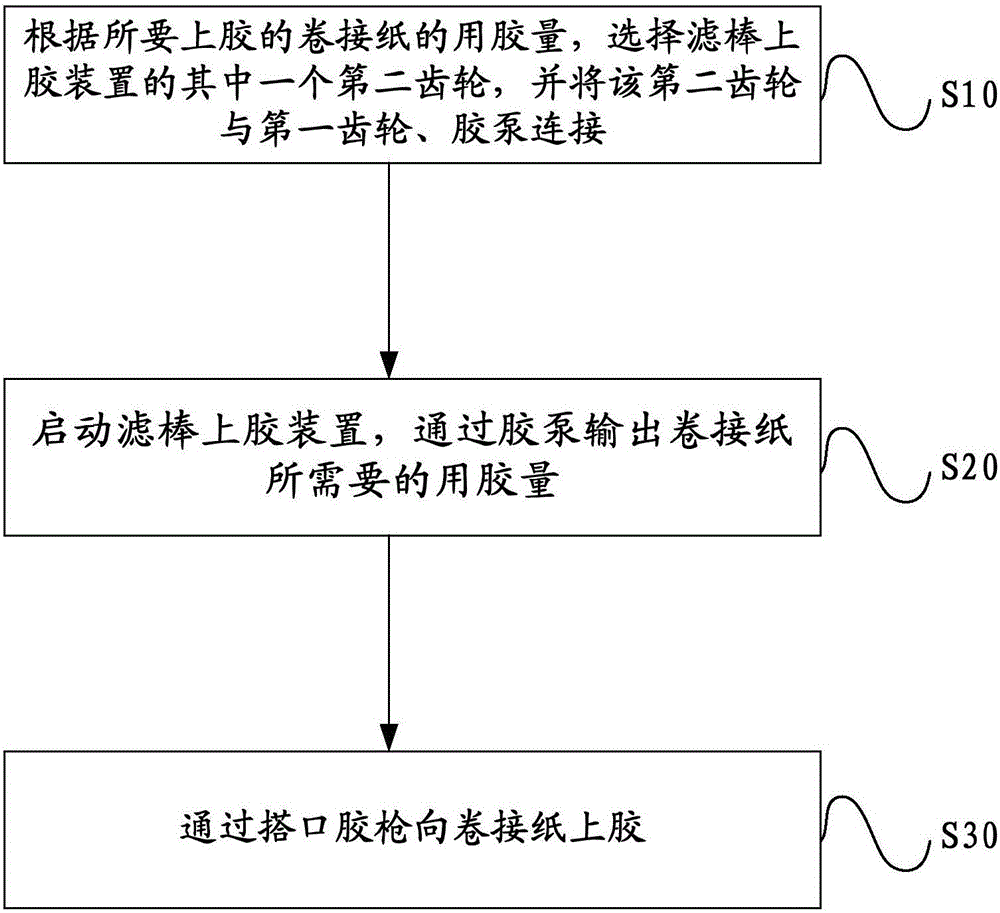

[0023] Combine below Figure 1 ~ Figure 2 The technical solution provided by the present invention is described in more detail.

[0024] An embodiment of the present invention provides a filter rod gluing device, including a glue pump 8 and a transmission chain; the transmission chain includes a first gear 1 and a second gear 3, the first gear 1 is driven by a power unit, and the number of the second gear 3 There are at least two, and the number of teeth of each second gear 3 is different. One of the second gears 3 meshes with the first gear 1 and the second gear 3 is drivingly connected with the glue pump 8 .

[0025] The second gear 3 can mesh with the first gear 1 directly or through a synchronous belt 4 . The middle part of the second gear 3 is provided with a transmission shaft 5, through which the transmission shaft 5 is drivingly connected with the rubber pump 8.

[0026] The number of teeth of each second gear 3 is different. When the power device outputs the same po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com