Copper bar cutting equipment

A technology of cutting equipment and copper rods, applied in the field of copper rod cutting equipment, can solve the problems of high labor intensity of operators, uneven length of copper rods, and large use limitations, so as to improve cutting efficiency, avoid uneven cutting length, The effect of reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

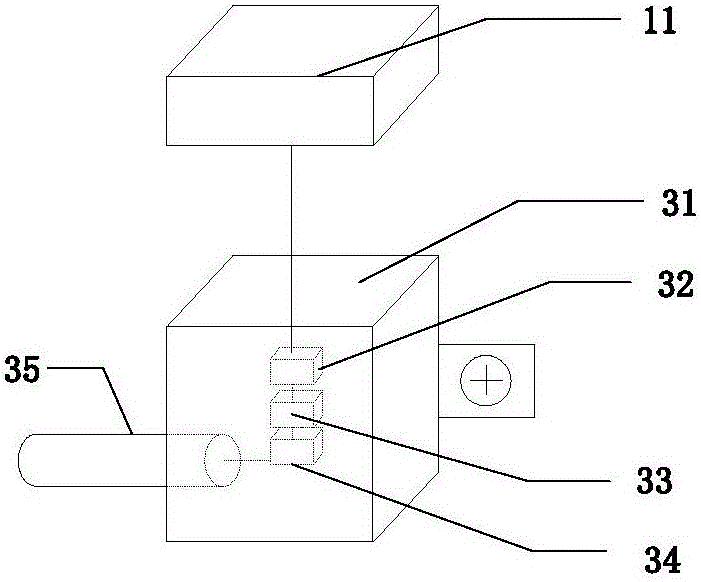

[0028] Specific implementation: the operator inserts the plug 94 into the socket, the plug 94 transmits the electric energy to the charger 93 in the shell 91 through the power cord, and the charger 93 transmits the electric energy to the storage battery 92, thereby charging the storage battery 92, and the storage battery 92 is fully charged. After electrification, pull out plug 94, because the present invention has added accumulator 92, charger 93 and plug 94, this design has changed the problem that original copper rod cutting equipment energy consumption is high, has saved electric energy, has reduced energy consumption, provides enterprise Reduced production costs.

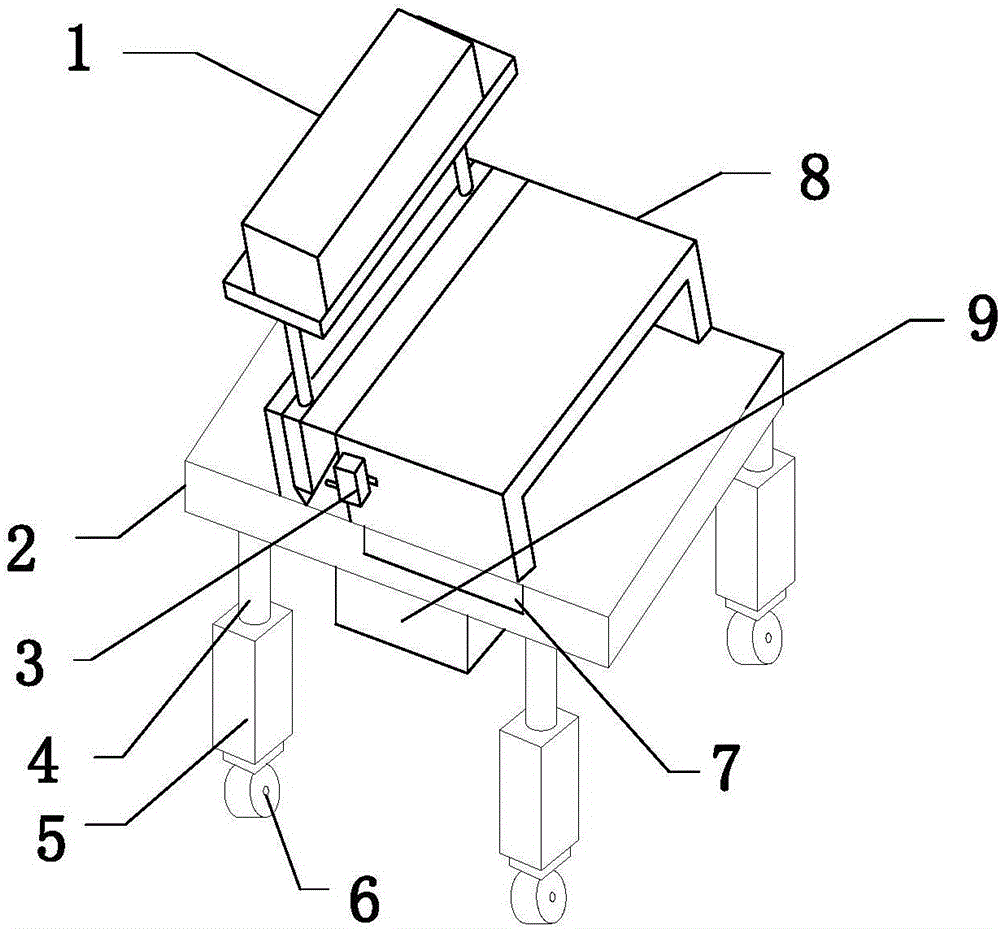

[0029]The operator promotes the workbench 2 according to the work site, and the workbench 2 drives the pulley 63 on the base 5 to rotate on the central axis 64. After the present invention moves to the work site, the operator presses the brake pad 65 on the pulley 63 to move The present invention is fixed, beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com