Bolt-fastened grinding wheel

A grinding wheel and fastening technology, applied in the direction of bonding grinding wheels, abrasives, metal processing equipment, etc., can solve the problems of grinding wheel chipping, affecting the service life of grinding wheel and grinding effect, etc., to eliminate chipping, ideal grinding effect, The effect of grinding process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

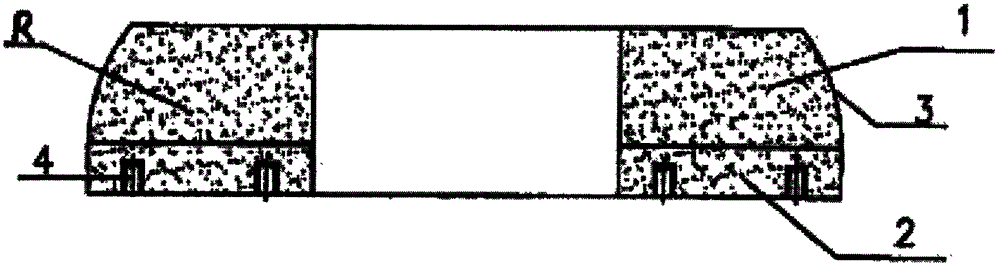

[0010] Referring to the accompanying drawings, the bolt-fastened flat grinding wheel is code-named 36-600×80×305WA / F46N6V-35m / s, and its working part 1 is a vitrified bonded grinding wheel with a thickness of 60mm; the mounting part 2 is embedded with a metal nut 4 Resin bond grinding wheel, thickness 20mm. The peripheral portion of the outer end surface of the working part 1 is an arc-shaped profile 3 with an arc radius R=180mm.

[0011] The above descriptions are only preferred embodiments of the present invention, and all equivalent changes and modifications made according to the scope of the patent application of the present invention shall fall within the scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com