Polar plate processing method of accumulator

A processing method and storage battery technology, applied in the direction of lead-acid battery electrodes, electrode manufacturing, electrode carrier/collector, etc., can solve problems such as lead leakage, virtual welding, battery short circuit, etc., to improve product qualification rate, shorten process flow, The effect of extending the service life

Inactive Publication Date: 2008-10-29

ZHEJIANG ZHENLONG BATTERY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the low cutting accuracy of the saw blade, the lug lengths of the pole plates obtained by cutting are inconsistent; the grinding process of the wire brush is manually controlled, and the degree of force is different for each operation, so the grinding degree of each pole plate is not the same, resulting in Uneven tab thickness

When the plate is welded, it is easy to cause the plates to fall off, virtual welding, lead leakage, etc., which will cause a short circuit of the battery.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

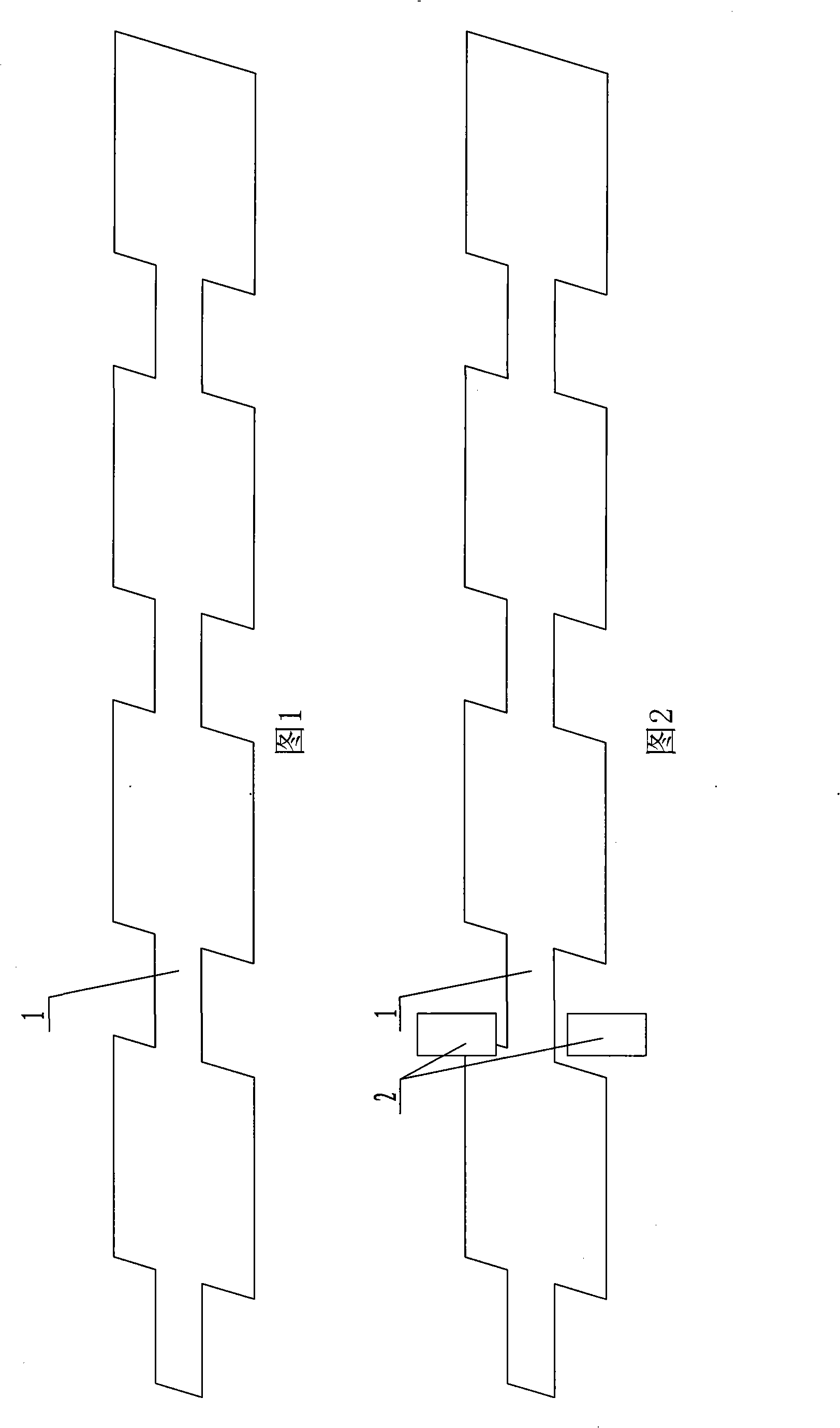

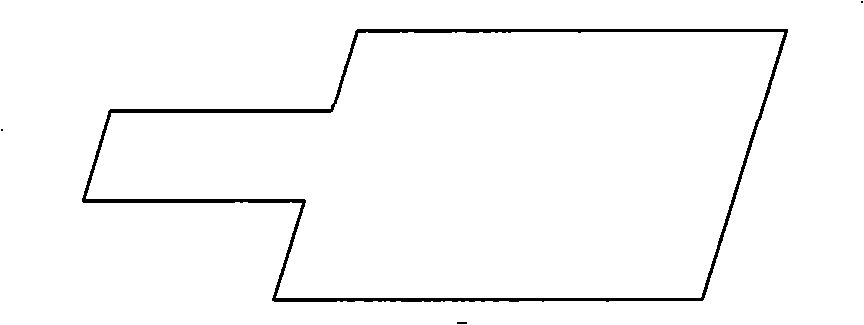

The invention discloses a processing method of the polar plate of a storage battery. Firstly, lead paste is coated on a grid; secondly, the grid coated with the lead paste is solidified and dried to form a multi-piece-link polar plate; thirdly, the multi-piece-link polar plate is cut and when cutting, each multi-piece-link polar plate is put into a milling machine independently; two opposite milling cutters at the vertical direction of the milling machine cut the multi-piece-link polar plate vertically to produce a single-piece polar plate and after cutting, the milling cutters are separated in a certain distance to brush the surface of the tab of the polar plate. The polar plate with tabs of the same length and the same thickness is produced by the milling machine with the working characteristic of high precision. The original cutting and brushing procedures are finished by the milling machine in one step, which shortens process flow, prevents the quality of the product from being affected by the processing operation of different precisions and improves the qualification rate of products. Besides, the appearances of chip shell, fault soldered joint, lead leakage, etc. occured during the original polar plate welding do not exist and the service life is prolonged.

Description

A kind of pole plate processing method of storage battery technical field The invention relates to a method for processing pole plates of storage batteries. Background technique In the production of battery plates, multiple plates are stacked and cut into individual pieces with a high-speed rotating saw blade, so multiple small pieces can be obtained in one cut, and then the surface of the tabs of the plates is brushed with a wire brush to remove the poles. The oxide layer on the surface of the ear. Due to the low cutting accuracy of the saw blade, the lug lengths of the pole plates obtained by cutting are inconsistent; the grinding process of the wire brush is manually controlled, and the degree of force is different for each operation, so the grinding degree of each pole plate is not the same, resulting in Tab thickness is uneven. When the plate is welded, it is easy to have plate drop, false welding, lead leakage and other phenomena, which will cause a short circuit o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/04H01M4/16H01M4/82

CPCY02E60/126Y02E60/10

Inventor 王定华刘为胜

Owner ZHEJIANG ZHENLONG BATTERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com