A kind of multi-frequency numerical control ultrasonic processing method, auxiliary device and processing drilling machine

An ultrasonic processing and auxiliary device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor surface quality and prone to edge chipping, and achieve the goal of solving edge chipping, improving processing efficiency and improving processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

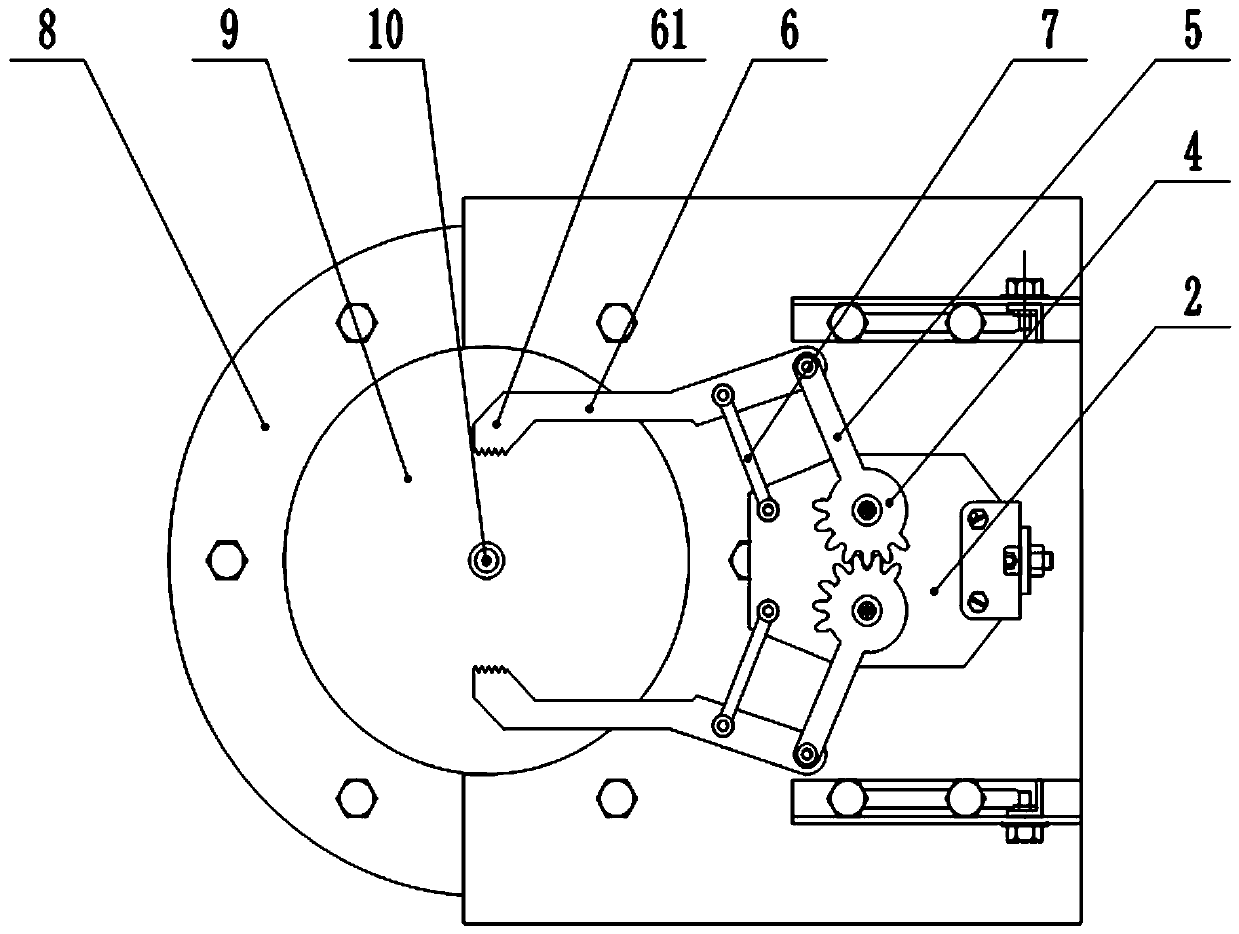

[0012] In the multi-frequency numerical control ultrasonic machining method of the present invention, when the tool enters or leaves the surface of the workpiece, the free mass block 12 is clamped by the clamping device, and the coupled low-frequency and large-amplitude vibration is removed, thereby realizing single-frequency Processing, improve processing quality, and solve the problem of edge collapse; when the tool is processing the inside of the workpiece, the clamping device is released to allow the free mass block 12 to vibrate freely, and a low-frequency and large-amplitude vibration is coupled to improve processing efficiency. The clamping device here can be a common mechanical structure such as a jaw cylinder, as long as it can satisfy the clamping and releasing of the free mass block 12 .

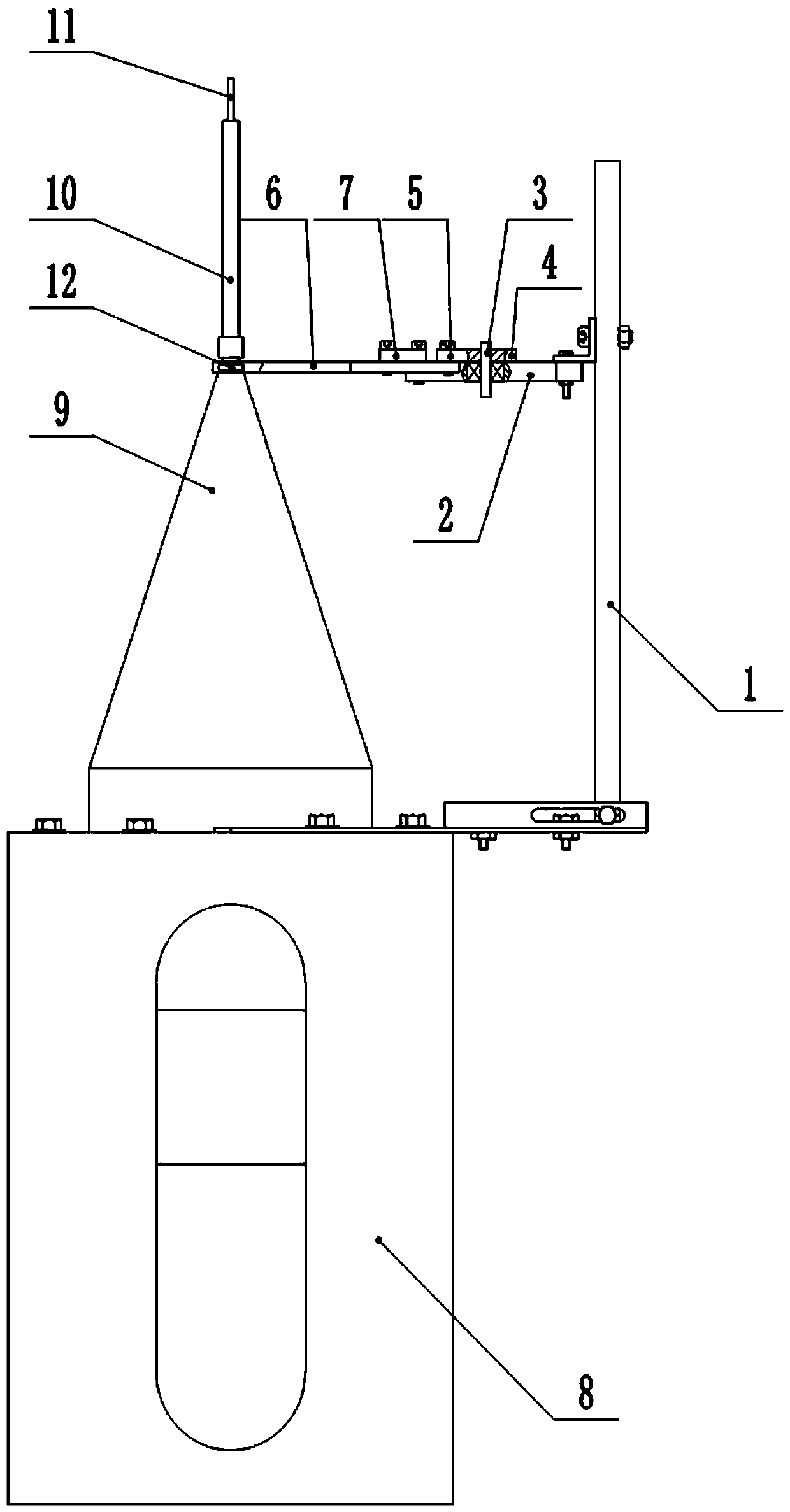

[0013] refer to Figure 1 to Figure 2 , the present invention also provides an auxiliary device for realizing the above-mentioned multi-frequency numerical control ultrasonic mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com