Fan anchor bolt foundation grouting steel formwork design method

A technology of foundation grouting and design method, which is applied in basic structure engineering, construction, etc., can solve the problems of unfavorable offshore wind power foundation transportation and construction, and achieve the effect of ensuring the quality of grouting construction, eliminating the risk of height difference, and reducing the difficulty of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

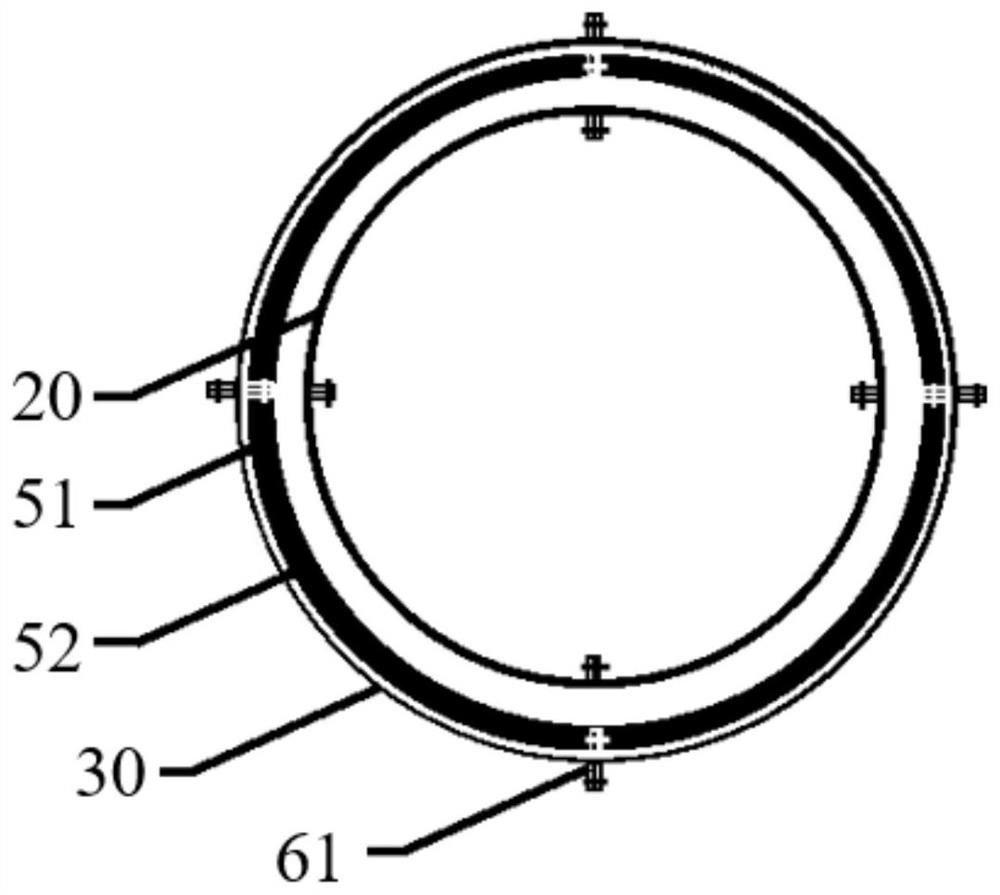

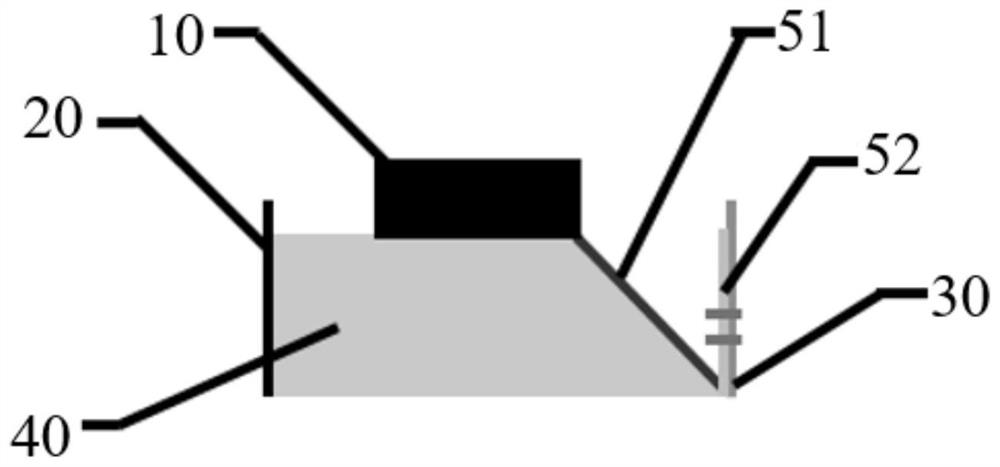

[0049] like Figures 1 to 4 As shown, in this embodiment, the inner diameter of the anchor plate 10 used is 6.2m, and the outer diameter is 6.8m. The distance between the anchor plate 10 and the foundation is 13 cm.

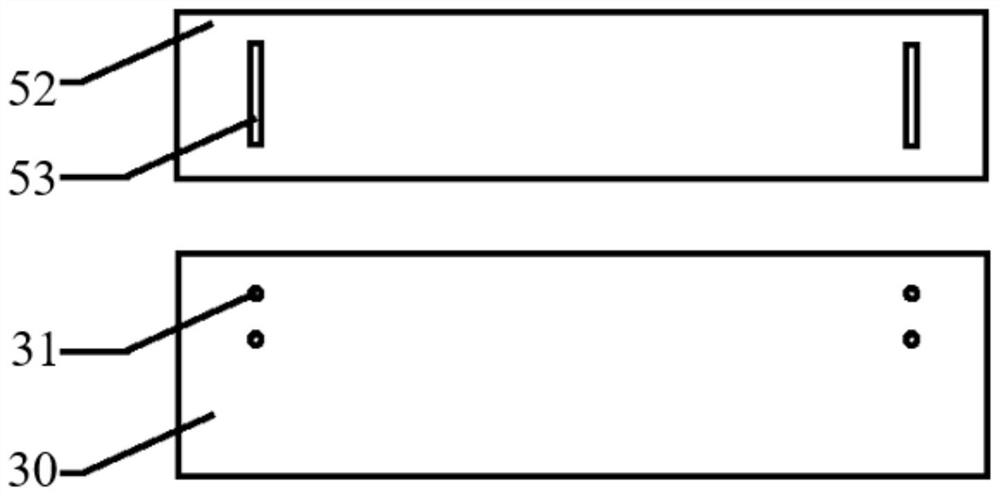

[0050] In the design method of the grouting steel formwork for the fan anchor bolt foundation in this embodiment, the formwork is divided into three layers of formwork, including an inner formwork 20, an outer formwork 30 and a middle formwork, and each layer of formwork adopts 8 modules with a central angle of 90°. Since the site structure in this embodiment is relatively large, 8 modules can meet the on-site transportation requirements,

[0051] The outer diameter of the inner formwork 20 is 6m, and the inner diameter of the anchor plate 10 is spaced by 10cm, which facilitates the transportation and ramming of the grouting material 40 during grouting. When the modules of the inner formwork 20 are installed, a wedge-shaped rubber block with a thickness of 1-2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com