Filter membrane clamp clamping device of air particle sampler

A filter membrane clamp and particulate matter technology, which is applied to sampling devices, workpiece clamping devices, manufacturing tools, etc., can solve the problems of time-consuming and laborious loosening and tightening, inconvenient operation of replacing filter membrane clamps, etc., and achieves convenient and simplified use. The operation of replacing the filter membrane, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

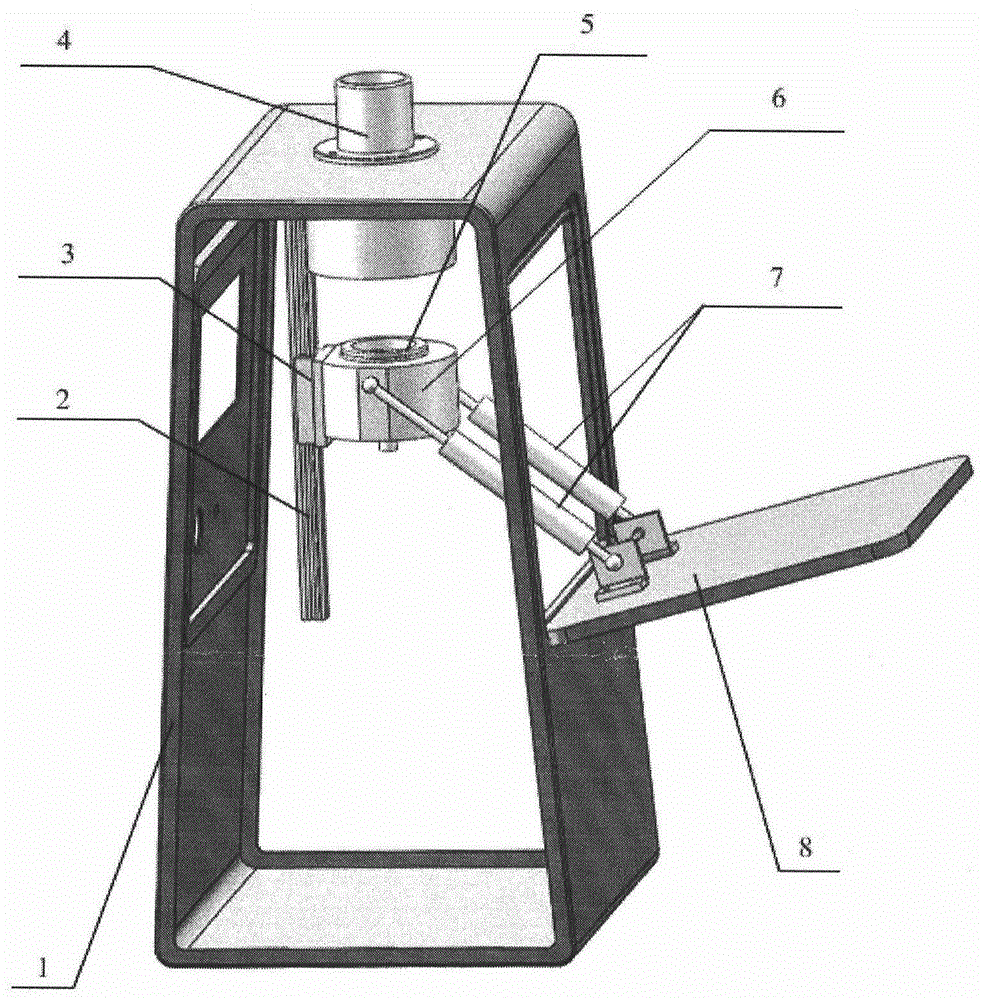

[0009] exist figure 1 Among them, the connecting body (4) and the linear guide rail (2) are fixedly connected to the chassis (1), and the filter holder tray (6) is fixedly connected to the slider (3), which can slide up and down along the linear guide rail (2), elastically Both ends of the ejector rod (7) are respectively hinged to the filter holder tray (6) and the instrument door (8). When the instrument door (8) is closed upward, the instrument door (8) pushes the filter holder tray (6) to slide upward along the linear guide rail (2) through the elastic ejector rod (7). When the instrument door (8) is closed, the filter Membrane holder tray (6) Press the membrane holder (5) upwards on the lower surface of the connecting body (4), and the elastic ejector rod (7) is compressed to a certain extent, and the elastic force generated reliably holds the membrane holder tray (6) upward compressive force. When the instrument door (8) is opened downward, the instrument door (8) pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com