Belt conveyor with linear detector

A belt conveyor and detector technology, which is used in conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problem of limited space for temperature measurement optical cables, reduce the working distance of detection optical fibers, and cannot directly detect the roller temperature. and other problems, to achieve the effect of high reliability, fast real-time response, and low false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

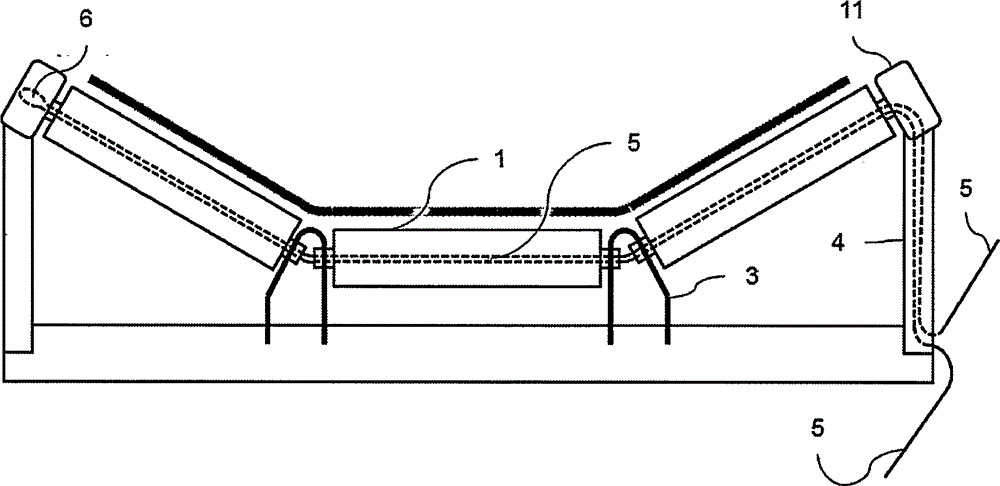

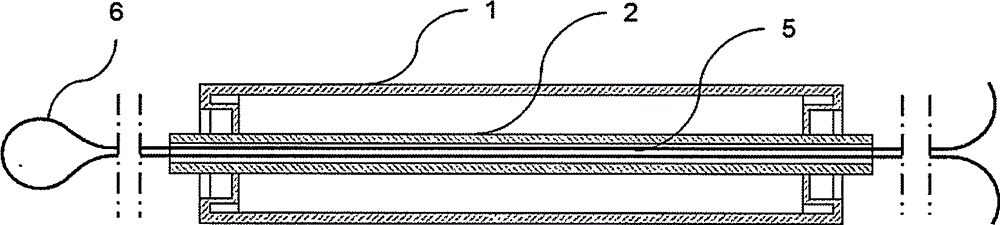

[0031] Refer to attached figure 1 And attached figure 2 , a realization scheme of a belt conveyor with a temperature-measuring optical cable is given:

[0032] The shaft 2 of the idler 1 is inserted into the groove on the idler bracket 3 and the idler support 4 through the flat groove on it; the shaft 2 is made of 45 seamless steel pipes through turning, milling, heat treatment and other processes , inner diameter 20mm, outer diameter 30mm.

[0033] The linear detector 5 is an optical cable with a built-in multimode optical fiber (including the outer diameter of the coating layer of 600 microns), spiral steel wire armor, the tensile part is aramid fiber, the outer sheath is flame-retardant plastic, and the outer diameter is 2.2mm , the instantaneous minimum bending radius is 6mm, and the short-term allowable tensile force is 200kN; after the optical cable passes through the channel of the shaft of a trough-shaped idler group in turn, it turns back according to the original ...

Embodiment 2

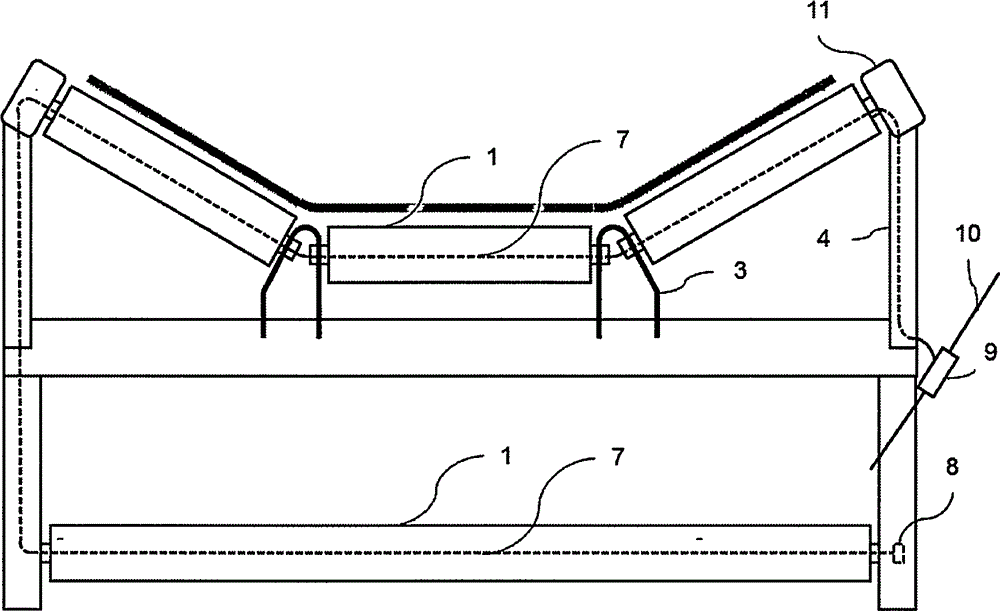

[0038] Refer to attached image 3 , a realization scheme of a belt conveyor with a branch-type temperature-sensing cable is given:

[0039] The shaft 2 of the idler 1 is inserted into the groove on the idler bracket 3 and the idler support 4 through the flat groove on it; the shaft 2 is made of 20-gauge steel seamless steel pipe through turning, milling, heat treatment and other processes , inner diameter 10mm, outer diameter 25mm.

[0040]The linear detector 7 is a temperature-sensing cable branch line, double-core switch type, armored, and the outer sheath is flame-retardant plastic, with an outer diameter of 4.6mm; the temperature-sensing cable branch line passes through the shaft channel of a trough-shaped idler group in turn , and continue down the roller strut and pass through the channel of the shaft of a horizontal roller, forming a blind end at the other end of the channel and protected by a terminal piece 8. The temperature-sensing cable branch line is a branch whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com