Coating device with multiple evaporation sources and coating method thereof

A coating device and evaporation source technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems that the evaporation rate cannot be monitored and adjusted, and the requirements of controllable and economical coating cannot be met. Achieve the effect of high degree of automation, simple and reasonable device structure, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

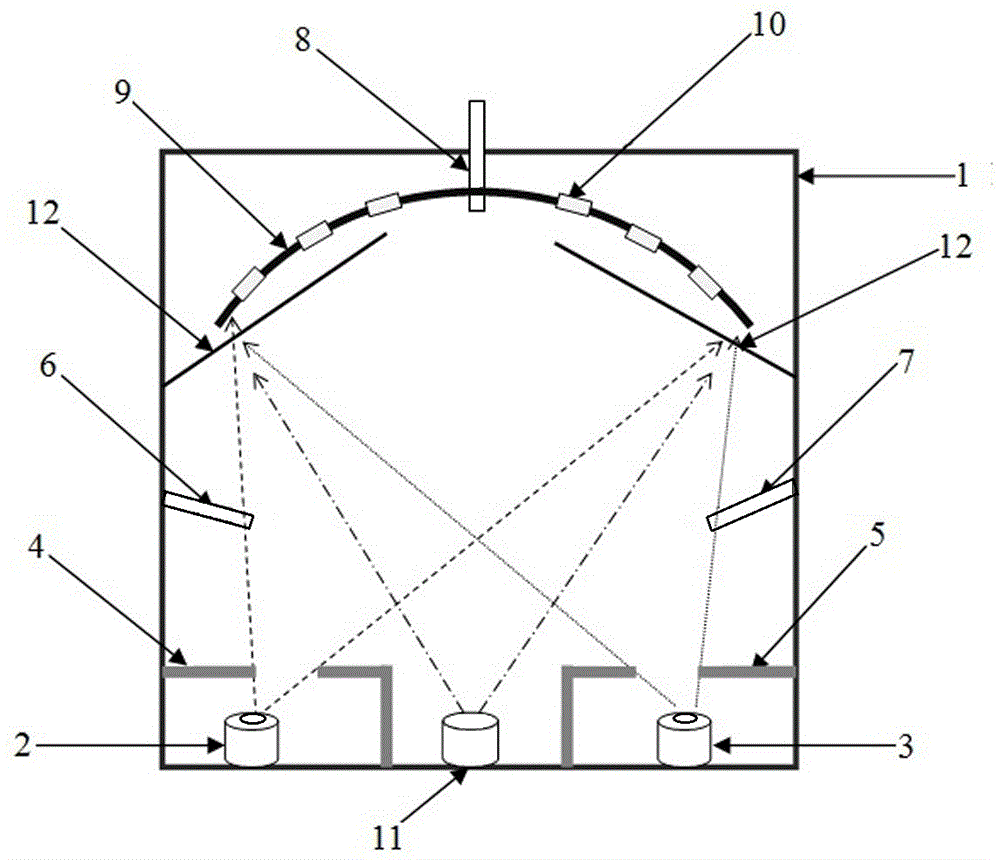

[0022] Example: such as figure 1 As shown, the multi-evaporation source coating device in this embodiment includes a vacuum coating chamber 1, and the inner chamber of the vacuum coating chamber 1 is used as a coating space. Taking two evaporation sources as an example, a first evaporation source 2 and a second evaporation source 3 are respectively provided at the bottom of the vacuum coating chamber 1. During film coating, put in the first evaporation source 2 and the second evaporation source 3 respectively Different film materials can be used to evaporate multi-component film layers. Above the first evaporation source 2 and the second evaporation source 3, a first baffle plate 4 and a second baffle plate 5 are respectively arranged, and openings are respectively arranged on the first baffle plate 4 and the second baffle plate 5, and the openings satisfy only allowable The requirement that the film material molecules of the partial evaporation angle emitted from the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com