Concrete-column cast-in-place structure movable-formwork supporting system and construction method

A technology of formwork support and concrete columns, which is applied to the joints of formwork/formwork/work frame, building structure, and on-site preparation of building components. It can solve the problems of long time occupation of mechanical equipment, slow construction progress, and labor costs. Problems such as high cost, achieving significant technical and economic benefits, reducing construction costs, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in combination with specific embodiments.

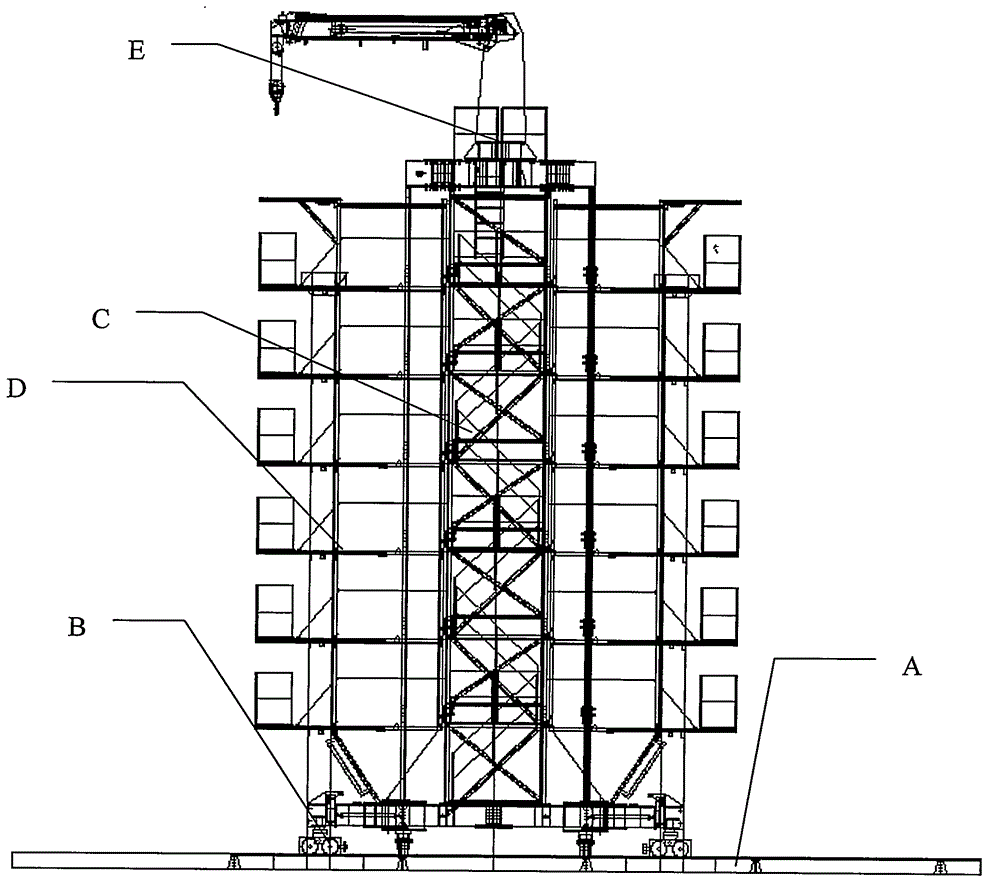

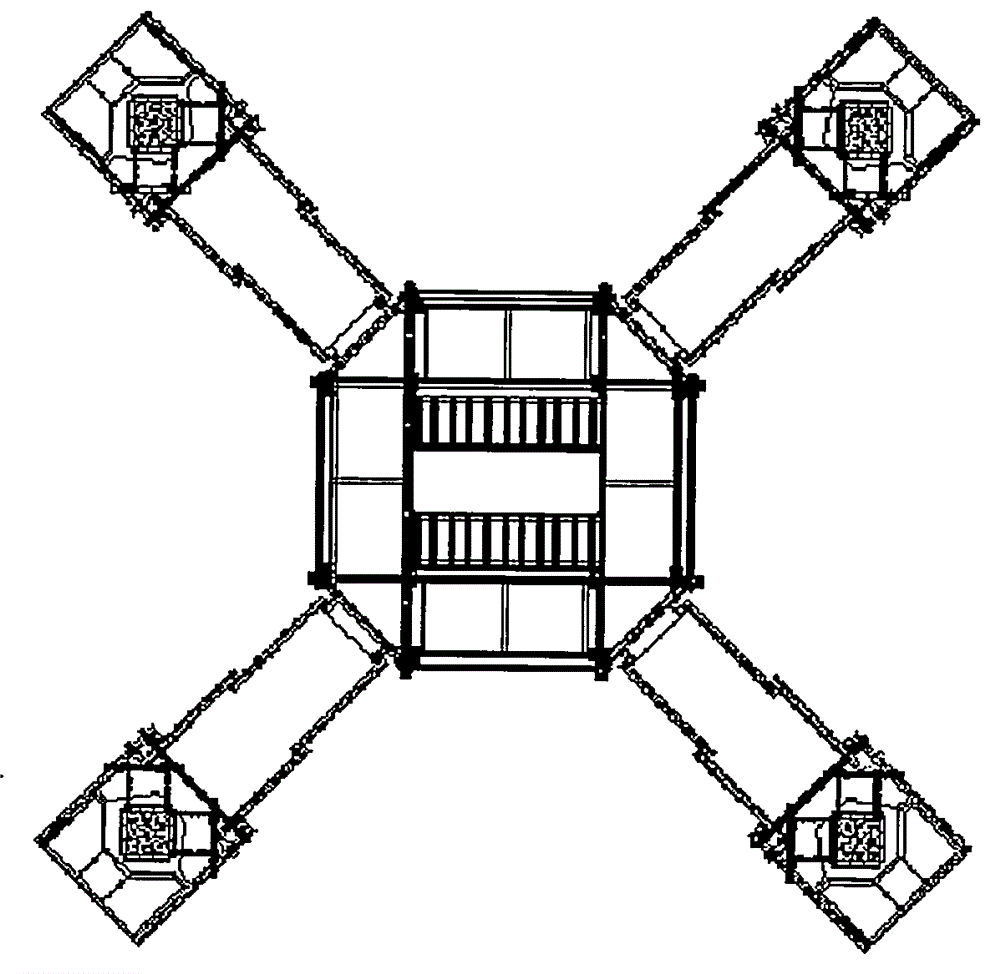

[0036] The mobile formwork support system of the concrete column cast-in-place structure of the present invention, such as figure 1 As shown, it includes track system (A), underframe system (B), frame structure system (C), turning platform formwork support system (D), top girder and crane system (E), which are sequentially installed before use. Assembled to form a whole.

[0037] The specific construction method is as follows:

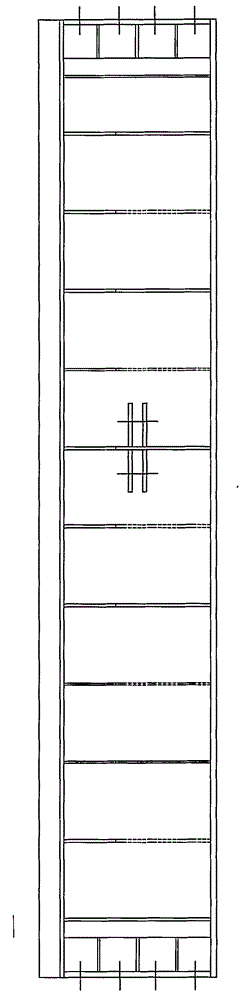

[0038] The first step is to make the track system ( image 3 , 4 ) are connected into a whole through bolts (1), and the whole is hoisted in place.

[0039] In the second step, after the welded inner beam (4) of the underframe is connected through the bolt (4) there, the inner web bar (7) and the outer inclined bar (3, 6) are connected through the pin shaft and the bolt Connect with the inner beam (4), and then connect the X direction wheel (9)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com