Pressure adjustor

A technology of pressure regulator and regulating cavity, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of oil production efficiency reduction, decline, and speed up oil pumping efficiency, so as to increase the contact area , to slow down, to avoid damaged effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

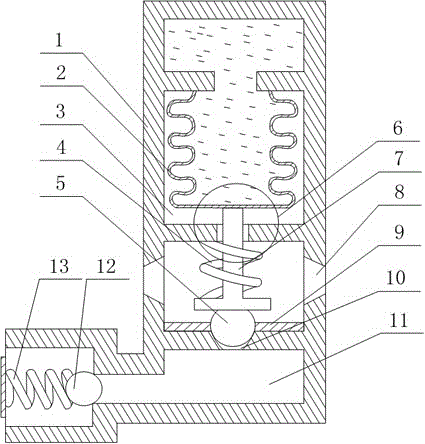

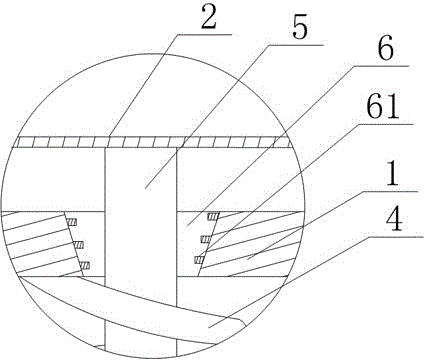

[0022] like figure 1 and figure 2 As shown, this embodiment includes a housing 1, in which a regulating chamber 3, an air intake chamber and a transition chamber 11 are sequentially opened from top to bottom, and the regulating chamber 3 is installed with a cylinder filled with compressed air. The airbag 2, and the adjustment chamber 3 communicate with the air intake chamber through the vent hole 6, the aperture of the vent hole 6 decreases downward along the axis of the push rod 7, and a spiral protrusion is installed on the inner wall of the vent hole 6 and along its axial direction 61, the air intake chamber communicates with the transition chamber 11 through the small hole 10, the transition chamber 11 communicates with the oil pipe, there are communication holes 8 on both sides of the air intake chamber, and a T is set in the middle of the air intake chamber type ejector rod 7, the return spring 4 is sleeved on the vertical section of the ejector rod 7, the top of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com