Infrared heating plate

A heating plate, infrared technology, used in heating fuel, heating method, electric heating system, etc., can solve the problems of easy aging of electric heating film, poor carbon stability, unstable heating, etc., to reduce indoor dust, no irritability, temperature balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

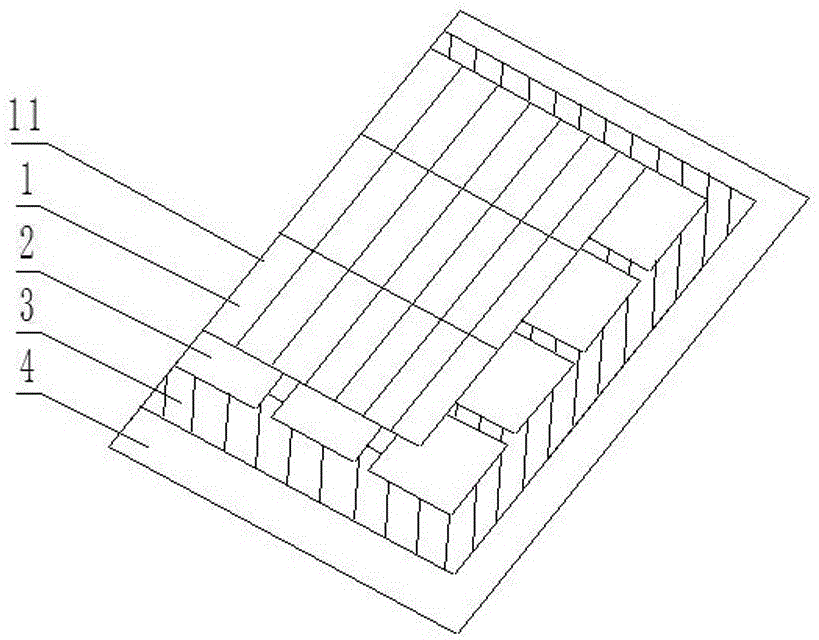

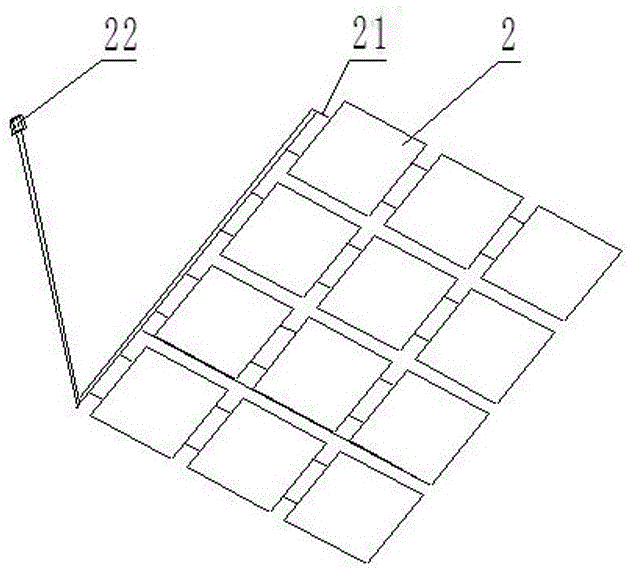

[0039] The leveled floor 1 is covered with a 20mm thermal insulation board 3, and then a silicon crystal infrared heating board 2 with a thickness of 0.8mm is laid. The power lines and water pipes are arranged along the walls to ensure the flatness and height of the floor; The wooden floor 11 with a thickness of 1.8-2.8cm is laid, and the wooden floor 11 is directly laid on the silicon crystal infrared heating plate 2 by splicing.

Embodiment 2

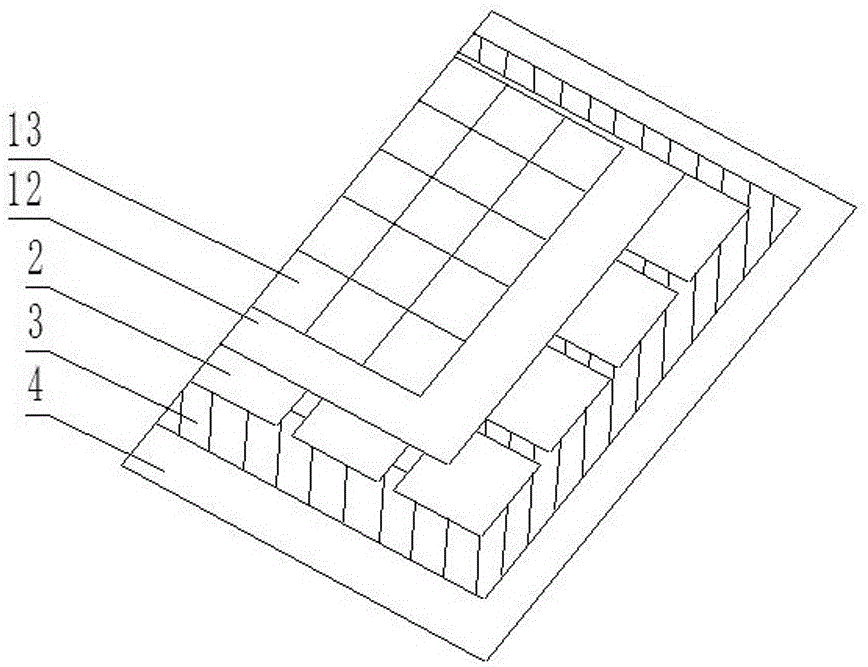

[0041] After leveling the floor 1, lay a 20mm insulation board 3 on it, and then lay a silicon crystal infrared heating board 2 with a thickness of 0.8mm. The power lines and water pipes are arranged along the walls to ensure the flatness and height of the floor; The cement layer 12 of 3-4cm is laid the floor tile that thickness is 1.2-2.2cm again.

Embodiment 3

[0043] After leveling the floor 1, lay a 20mm insulation board 3 on it, and then lay a silicon crystal infrared heating board 2 with a thickness of 0.8mm. The power lines and water pipes are arranged along the walls to ensure the flatness and height of the floor; The cement layer 12 of 1.9-2.1cm and steel wire barbed wire, lay the floor tile that thickness is 1.2-2.2cm again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com