Sectional loading and unloading test device in rock hole

A test device, segmented adding technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problem of inability to realize loading and unloading of various stress paths in rock holes, inability to simulate the unloading response process of excavated surrounding rock, Unable to perform segmental unloading tests in rock holes, etc., to achieve the effect of good sealing and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

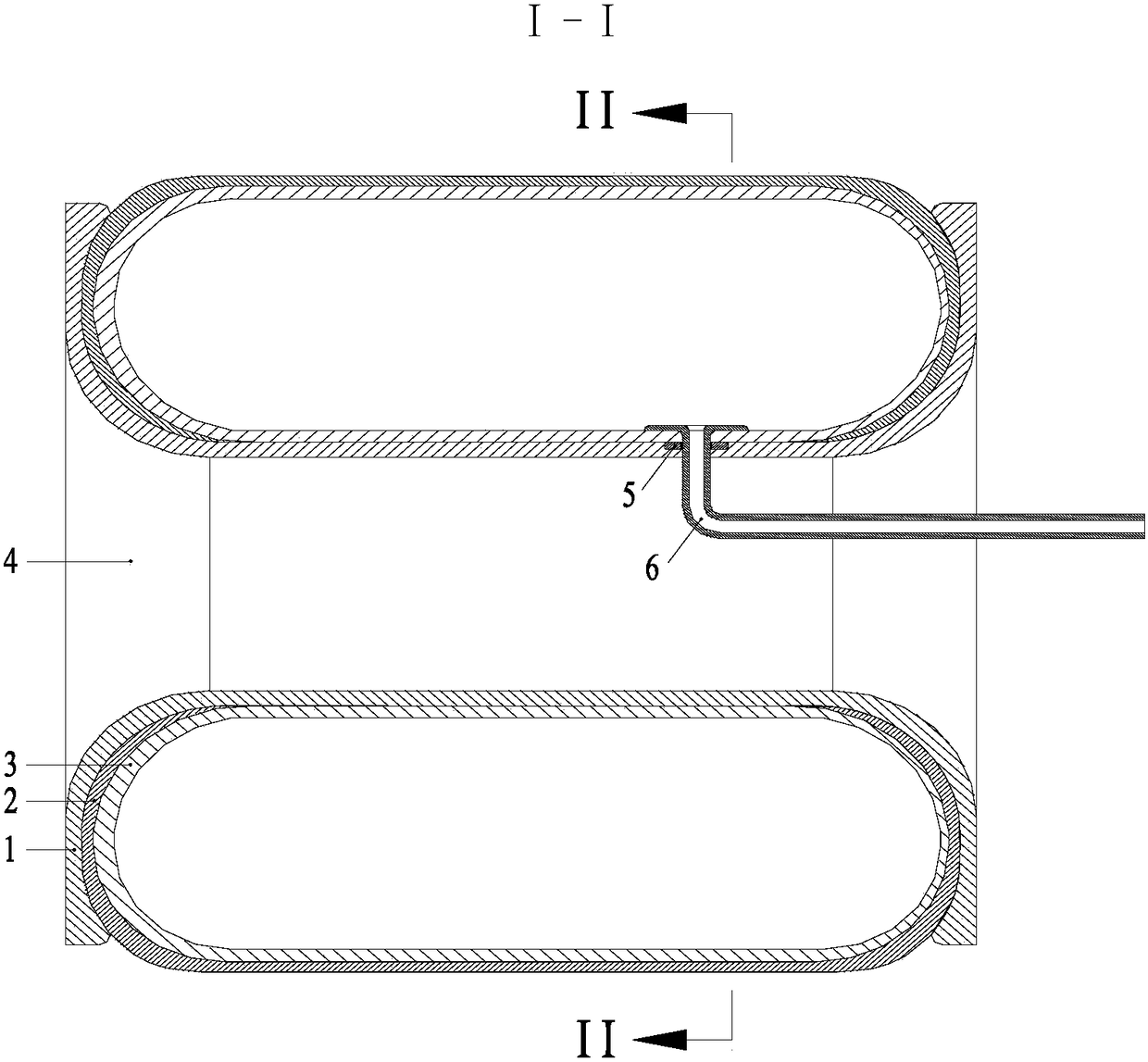

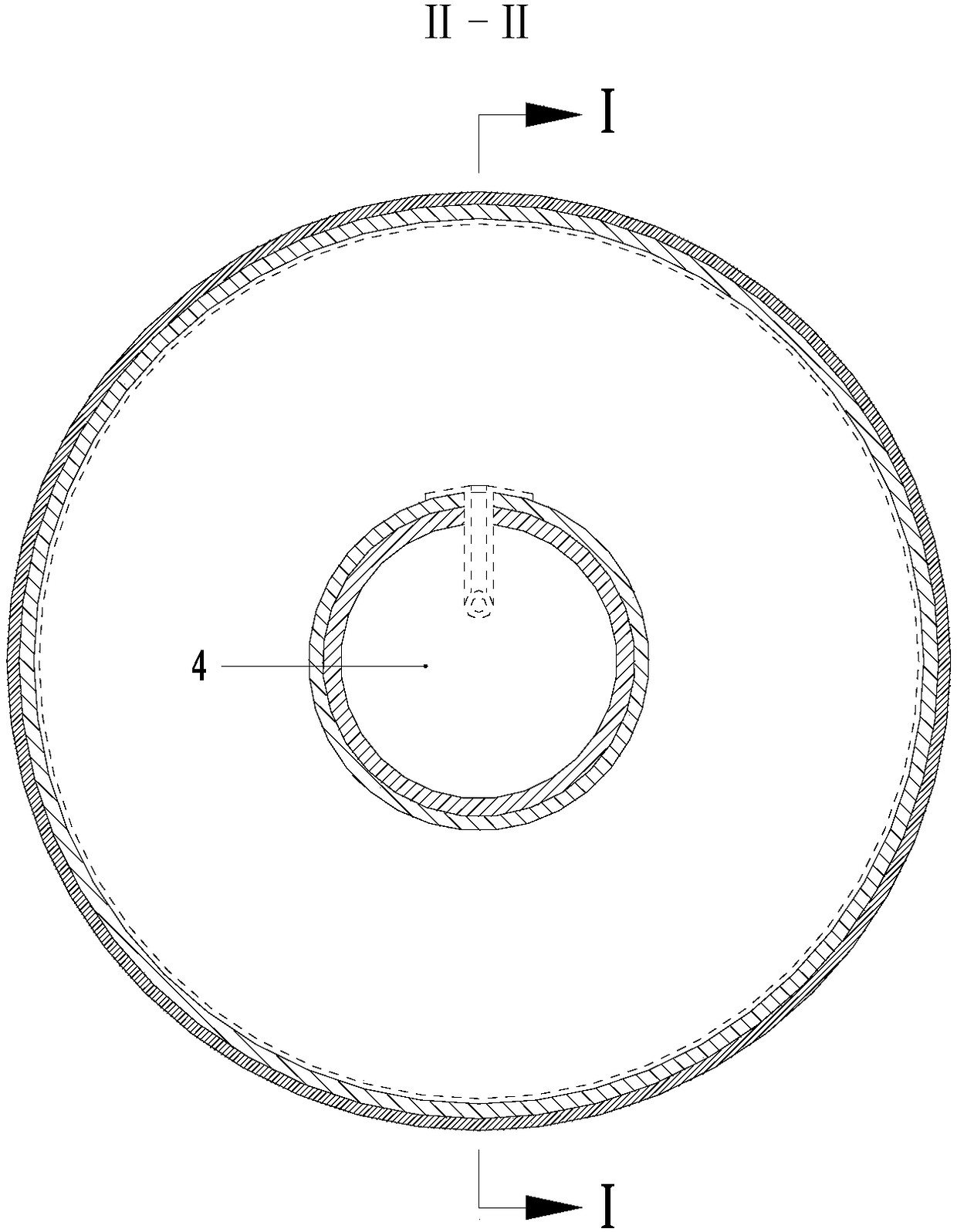

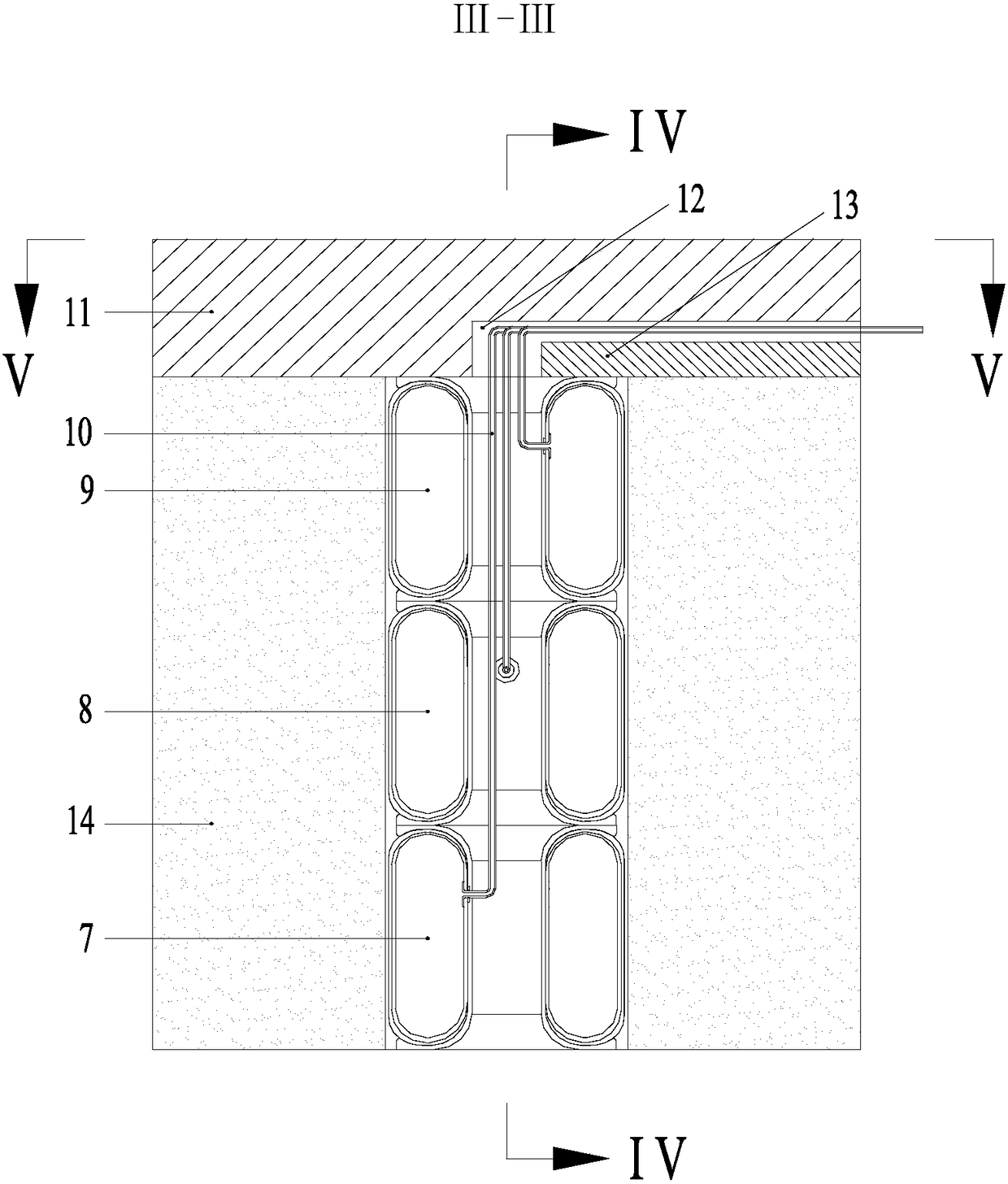

[0039] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a segmented loading and unloading test device in a rock hole, including a hydraulic loading and unloading device group in the hole, an end cover plate 11, a filling key 13, a hydraulic pipeline 10, an electro-hydraulic servo loading and unloading system and a control host 20, the hole The internal hydraulic loading and unloading device group is a multi-row single-row array composed of a plurality of in-hole hydraulic loading and unloading devices arranged in sequence along the central hole of the rock sample; The step-shaped pipe groove 12; the gap between the stepped pipe groove 12 and the end face of the rock sample 14 is filled by the filling key 13; the capsule plug pipe 6 of the hydraulic loading and unloading device in each hole is connected to an electro-hydraulic servo through the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com