Afterflow correction well test interpretation method of low-production horizontal well

A technology for well test interpretation and horizontal wells, applied in instrumentation, calculation, electrical digital data processing, etc., can solve problems such as low degree of bottomhole continuous flow correction, inconspicuous correction effect, and inability to obtain formation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

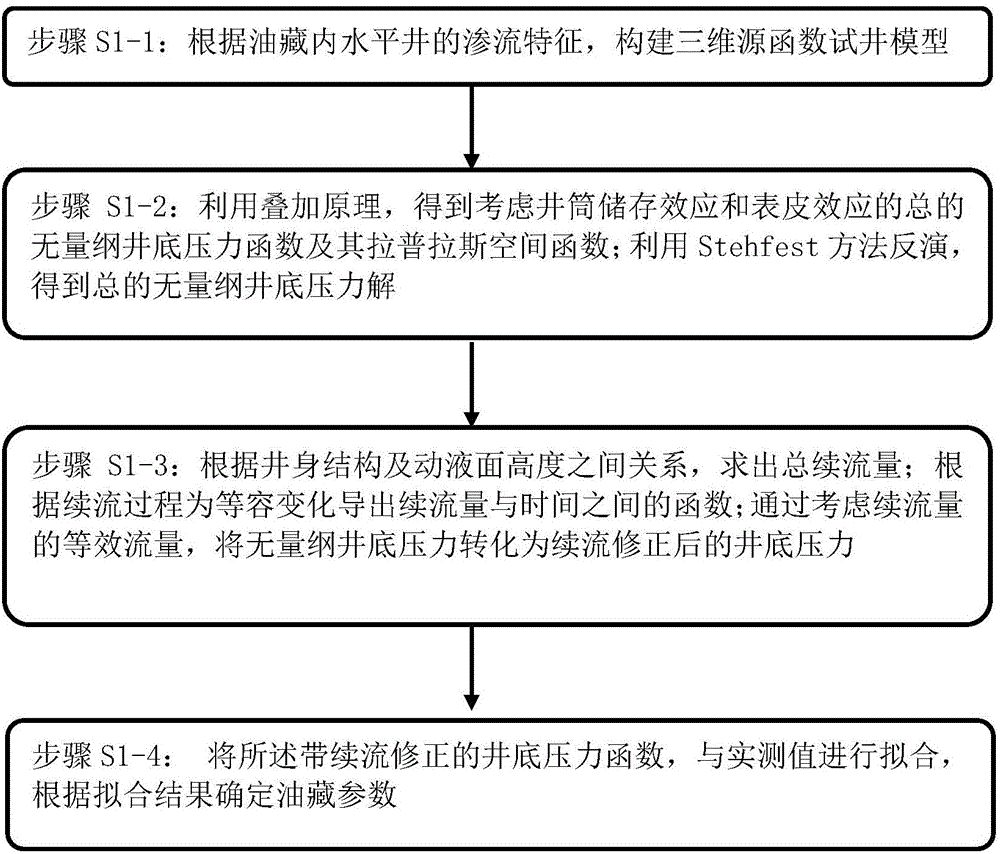

[0051] see Figure 1 to Figure 7 , a low-production horizontal well continuous flow correction well test interpretation method, comprising the following steps:

[0052] Step S1-1: According to the seepage characteristics of horizontal wells in the reservoir, construct a three-dimensional source function well test model;

[0053] Step S1-2: Using the superposition principle, obtain the total dimensionless bottomhole pressure function and its Laplace space function considering the wellbore storage effect and skin effect; use the Stehfest method to invert to obtain the total dimensionless bottomhole pressure solution ;

[0054] Step S1-3: Calculate the total freewheeling flow according to the relationship between the wellbore structure and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com