Method for solving low work efficiency in high-speed rotation of high-power brushless motor

A technology of brushless motor and high working efficiency, which is applied in the direction of electronic commutator, etc., can solve the problems of low working efficiency of the motor, achieve the effect of simple and convenient implementation, solve the problem of excessive temperature rise, and improve the current waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

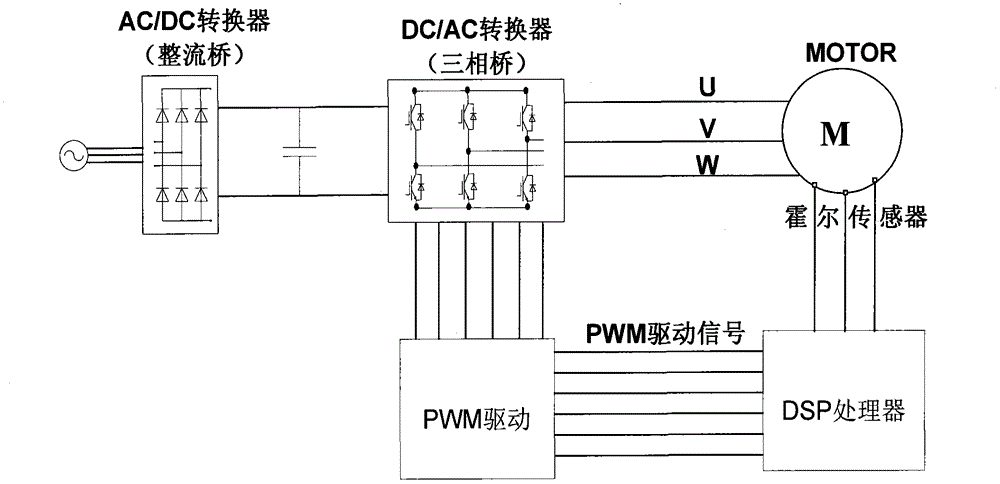

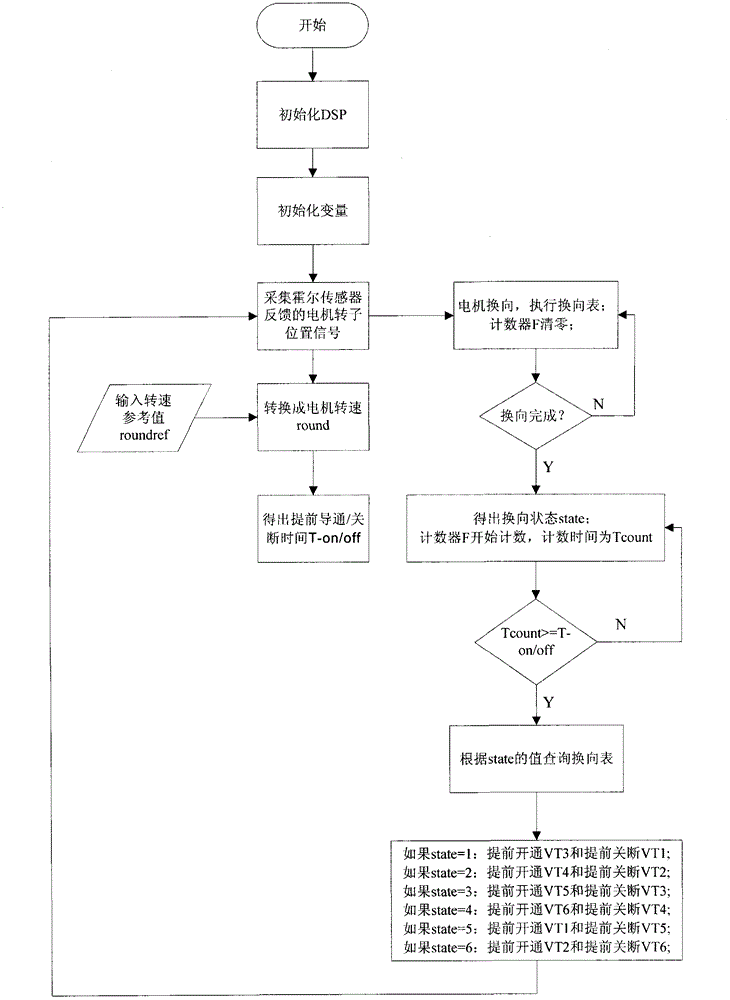

[0022] like figure 1 , 2 As shown, a method of the present invention to solve the low working efficiency of the motor due to the Hall position deviation at high speed of the high-power brushless motor is as follows:

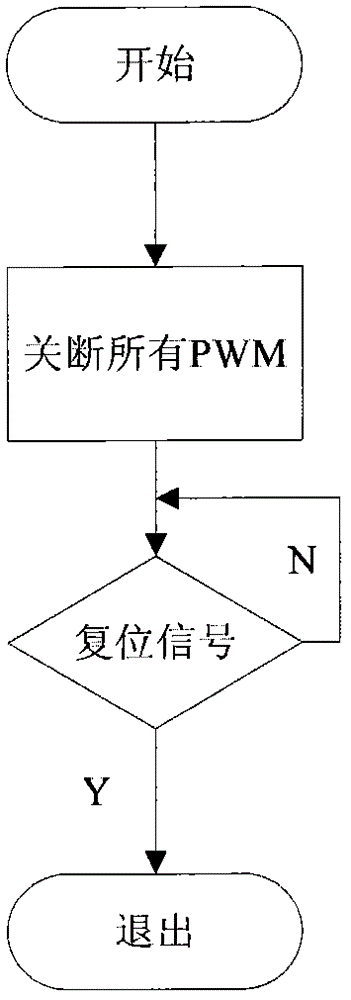

[0023] A method for solving the low working efficiency of a high-power brushless motor at high speed, including the step of capturing the speed of the brushless motor, the step of commutating the phase of the brushless motor, and the steps of turning on and off in advance, and measuring the motor speed through the step of capturing the speed of the brushless motor. The real-time speed can be used to obtain the amount of turn-on and turn-off in advance. The commutation step of the brushless motor realizes the commutation of the motor, and the step of turn-on and turn-off in advance realizes the turn-on and turn-off of the commutation drive signal in advance, so as to correct the error caused by the Hall installation. The commutation signal delay caused by the ina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com