Single lifting distributing platform for tubular workpiece

A technology for distributing tables and workpieces, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of difficult clamping and processing of tubular workpieces, increase the equipment footprint, and cannot be stacked to achieve production Low cost, simple and compact structure, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

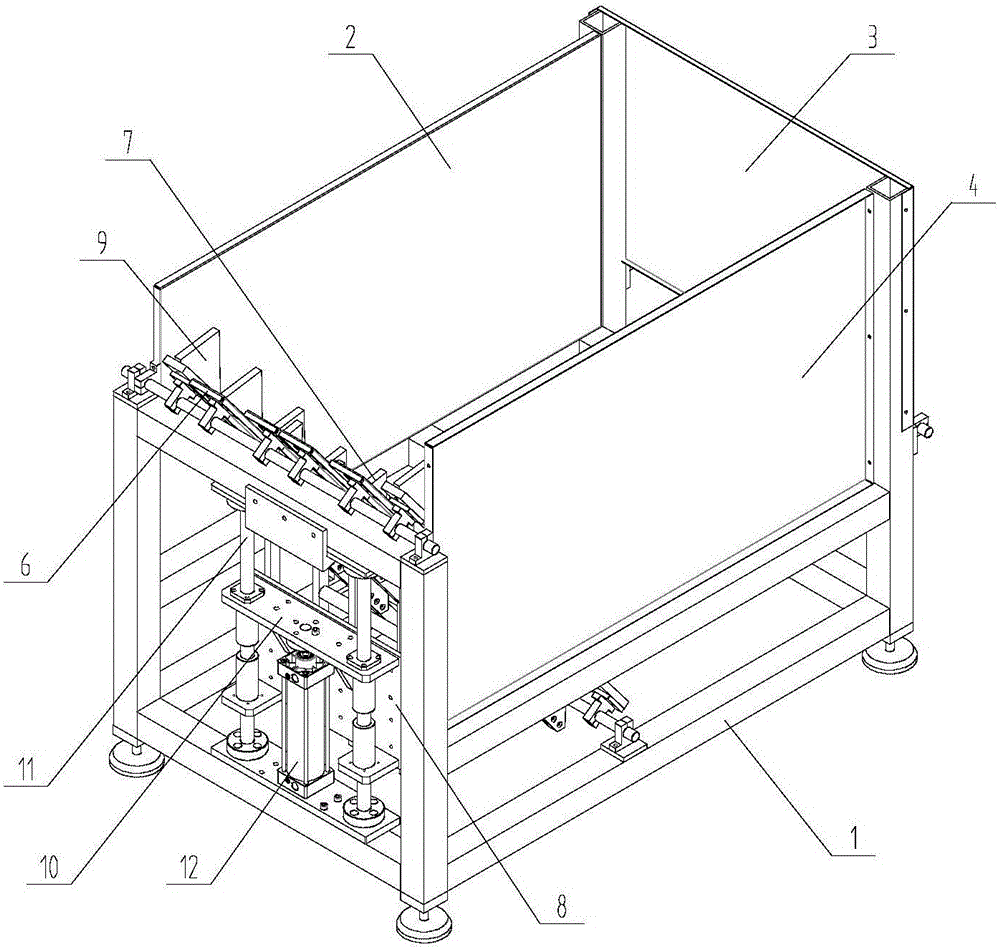

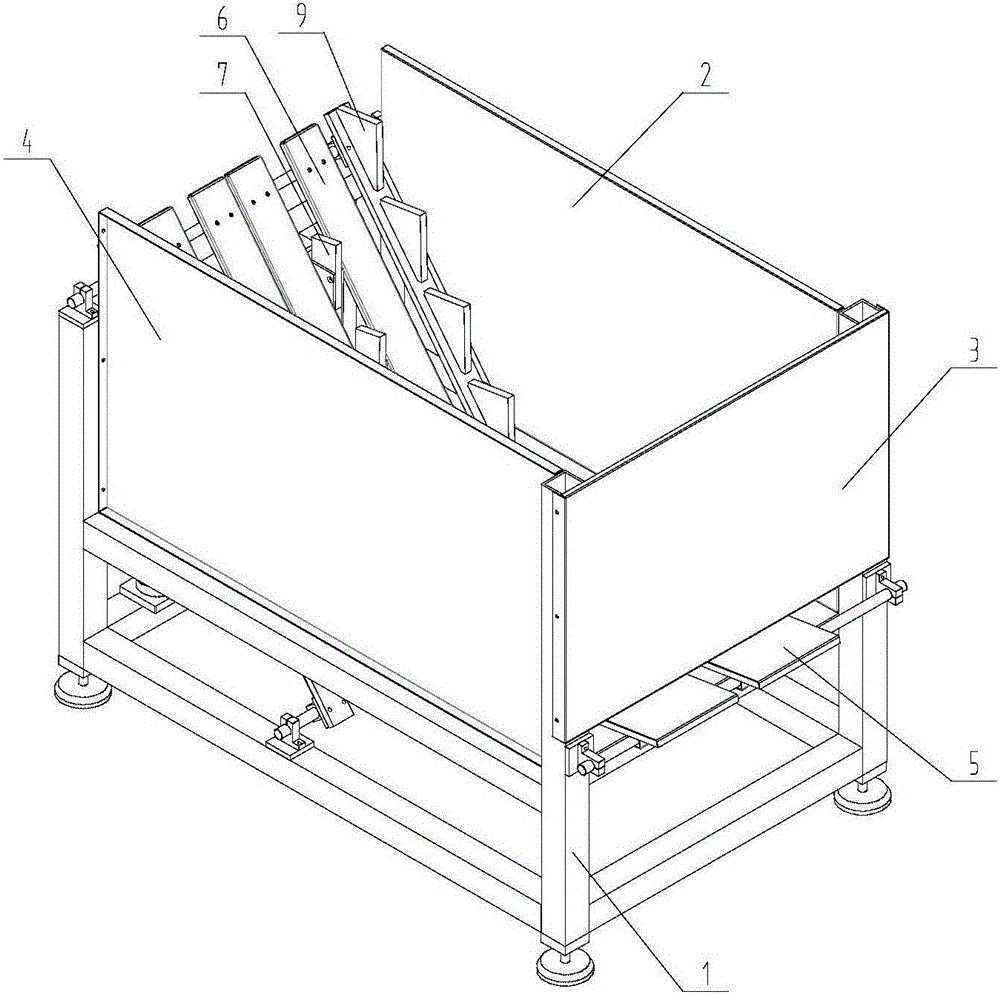

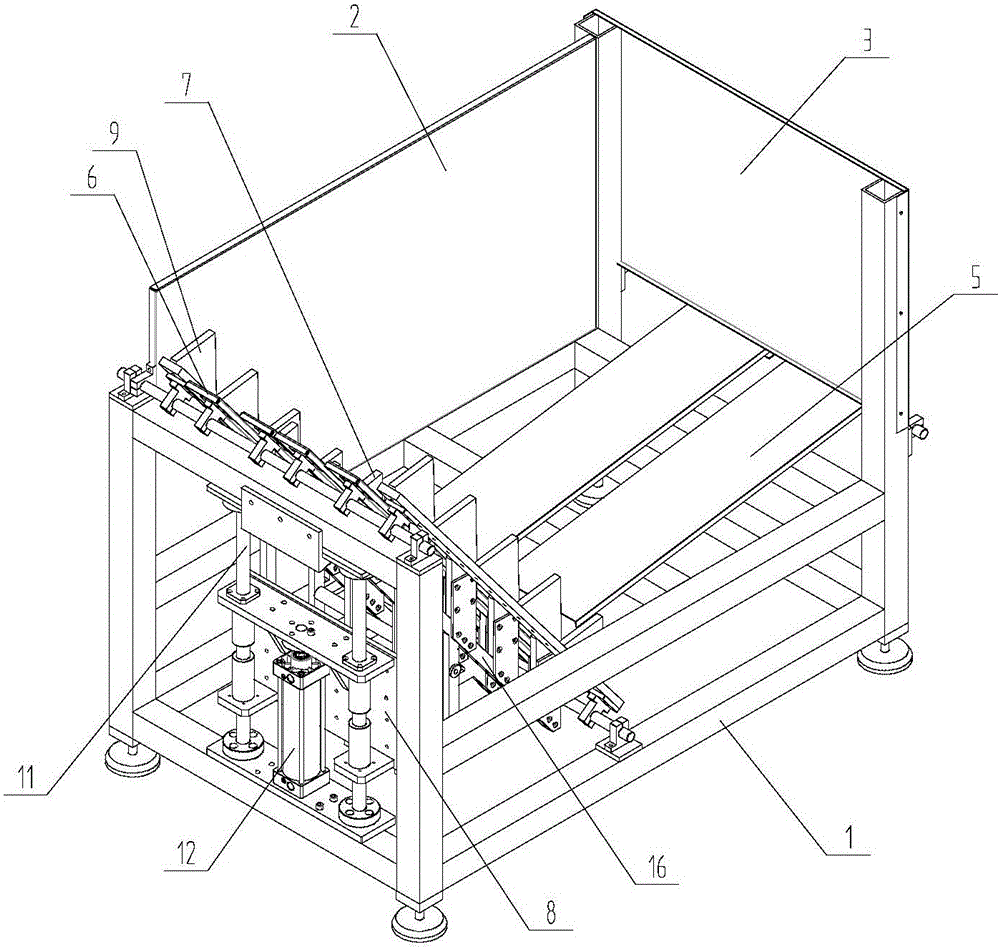

[0023] Such as Figure 1~6 As shown, a single lifting and distributing platform for a tubular workpiece includes a frame 1, a left baffle 2, a right baffle 3, a rear baffle 4, a storage plate 5, a lifting panel 6, a jacking plate 7, and a jacking and fixing Plate 8, slide block 10, linear guide rail 11 and linear cylinder 12, frame 1 is a frame made of aluminum profiles, and the bottom of frame 1 is provided with four supporting feet.

[0024] The material storage plate 5 is obliquely arranged on the bottom of the frame 1, the material storage plate 5 is inclined towards the lifting panel 6 direction and the inclination angle between the material storage plate 5 and the horizontal plane is 5-15 °, the material storage plate 5 can be a The whole straight board can also be a plurality of strip-shaped straight boards arranged in parallel, and the tubular workpiece can roll al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com