A kind of magnetostrictive serpentine moving transporter and its transporting method

A technology of magnetostriction and transportation method, applied in piezoelectric effect/electrostriction or magnetostriction motor, transportation and packaging, conveyor, etc., can solve problems such as complex structure, achieve low cost, no maintenance, The effect of increasing the effective use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

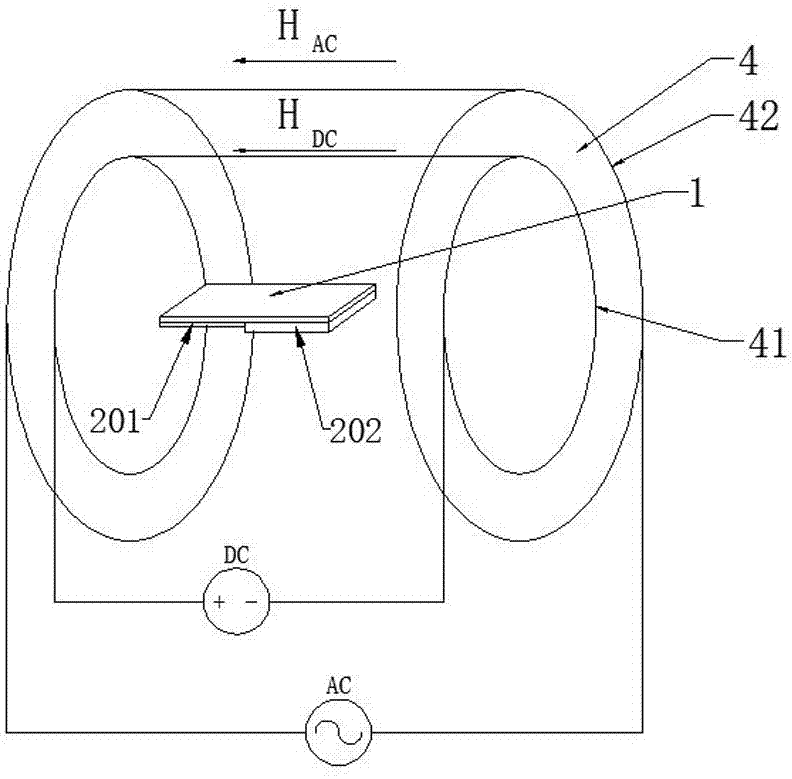

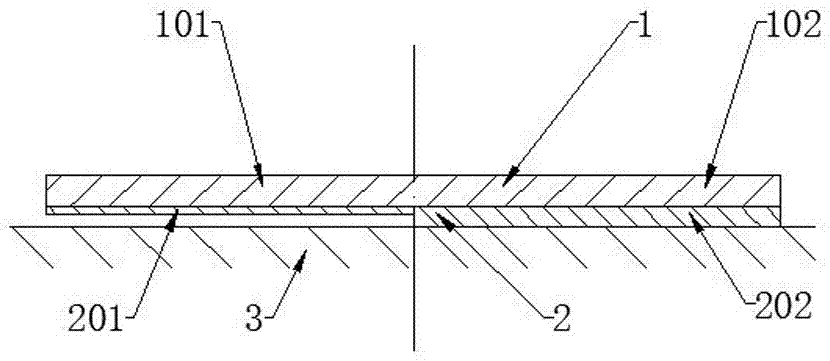

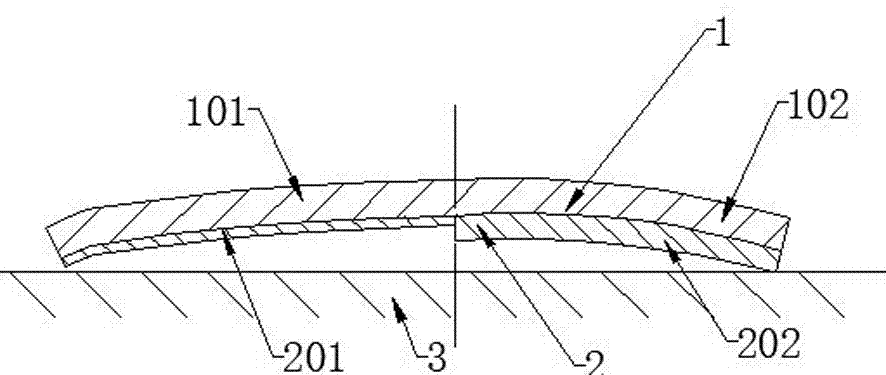

[0032] A magnetostrictive serpentine mobile transporter, comprising a base body and a coating layer, characterized in that: the transporter includes a base body 1 and a coating layer 2, and the base body 1 is a thin strip-shaped magnetostrictive material layer, in this embodiment The thickness of the middle matrix 1 is 30 μm, and the matrix 1 is made of a magnetostrictive material, and its magnetostriction coefficient is greater than 20ppm (10 -6 ); the substrate 1 is covered with a coating layer 2 made of non-magnetostrictive material on one side, and the coating layer 2 is divided into A' part 201 and B' part 202 along the length direction of the substrate 1, and A' part 201 and B' part 202 corresponds to the division of the substrate 1 into A part 101 and B part 102, A part 101 and A' part 201 form the driving part I, B part 102 and B' part 202 form the driving part II; A' part 201 and B' part The coating thickness of 202 is different, the thickness of A' part 201 is 15 µm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com