Spiral vertical lifting mechanism

A vertical lifting and spiral technology, which is applied in elevators, lifting equipment in mines, elevators in buildings, etc., can solve the problems of slow lifting speed, small diameter of jacking columns, and low work efficiency, so as to improve the service life , increase the support area, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

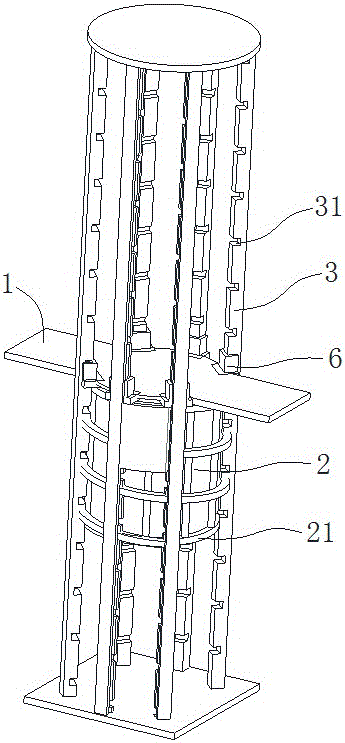

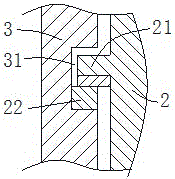

[0031] Embodiment 1: as Figure 1~Figure 3As shown, a spiral vertical lifting mechanism includes a horizontally arranged load-bearing plate 1, a lifting column 2 vertically installed at the bottom of the load-bearing plate 1 and capable of rotating around its own axis, and adjacent to the lifting column 2 along the circumferential direction. Several vertical columns 3 are arranged, and a driving device arranged between the bearing plate 1 and the lifting column 2 for driving the rotation of the lifting column 2; the circumferential surface of the lifting column 2 There is a helical edge 21 protrudingly arranged around the jacking column 2, the maximum diameter of the helical edge 21 is larger than the diameter of the inner common tangent circle of the several columns 3, and the minimum diameter of the helical edge 21 is smaller than the several The diameter of the outer common tangent circle of the column 3; the side of the column 3 facing the lifting column 2 has guide groove...

Embodiment 2

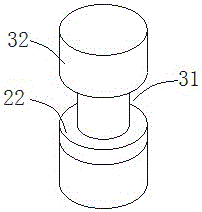

[0047] Embodiment 2: as Figure 4 As shown, the difference from Embodiment 1 is that the upward facing surface of the guide groove 31 also has a concave spherical hole, and a rolling ball is embedded in the spherical hole, and the upper end of the ball is exposed. on the surface.

[0048] In this way, since the upper end of the ball exposes the upward surface of the guide groove, the lower surface of the helical edge fitted in the guide groove is in contact with the ball. Rolling in the spherical hole, so that the sliding friction between the helical edge and the guide groove is changed into rolling friction, which is beneficial to improve the flexibility of movement, reduce wear and improve the service life.

[0049] During implementation, the lower surface of the helical rib 21 has a groove arranged along the helical rib, the cross section of the groove is arc-shaped, and the radius of the arc is consistent with the radius of the ball; the depth of the groove is consistent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com