Ultraviolet lamp tube fixing device in marine ballast water system

A fixed device, ballast water technology, applied in natural water treatment, water/sewage treatment, illumination water/sewage treatment, etc. Tight fit and better fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

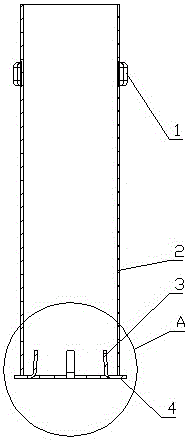

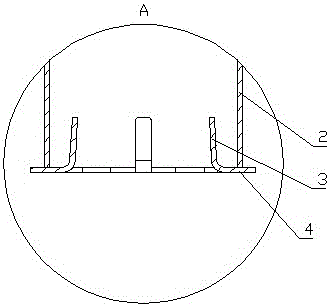

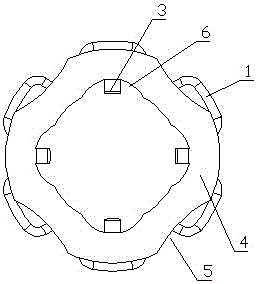

[0019] Such as Figure 1-5 The ultraviolet lamp fixing device in the marine ballast water system shown is provided with a support sleeve 2, and an elastic foot 1 is provided on the outer wall of the support sleeve 2, from which Figure 4 , Figure 6 It can be seen from the figure that two groups of elastic legs are arranged in the axial direction of the support sleeve, each group has three elastic legs, and the three elastic legs of each group are arranged on the support sleeve evenly in the circumferential direction; or on the outer wall of the support sleeve. Fabric elastic feet; from Figure 5 It can be seen from the figure that the elastic leg is in the shape of a square block, the outer surface of the elastic leg is an arc surface that closely fits with the inner wall of the quartz sleeve, the inner surface of the elastic leg is an arc surface that is closely matched with the outer wall of the support sleeve, and the inner surface of the elastic leg is Closely fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com