Device for cutting burrs of cloth

A fabric raw edge, No. 1 technology, applied in the cutting of textile materials, spray/jet textile material processing, textiles and papermaking, etc., can solve the problems of different raw edges, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

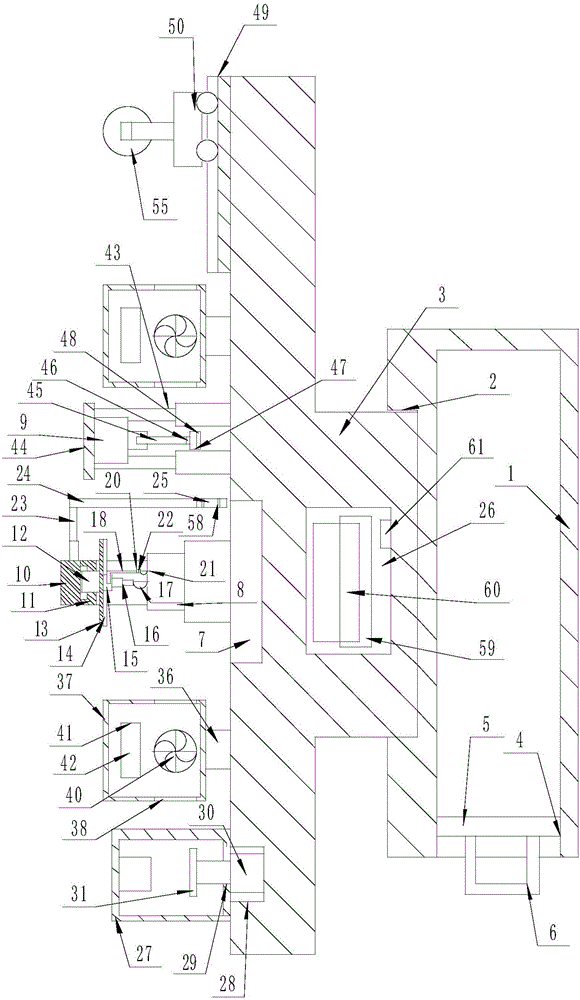

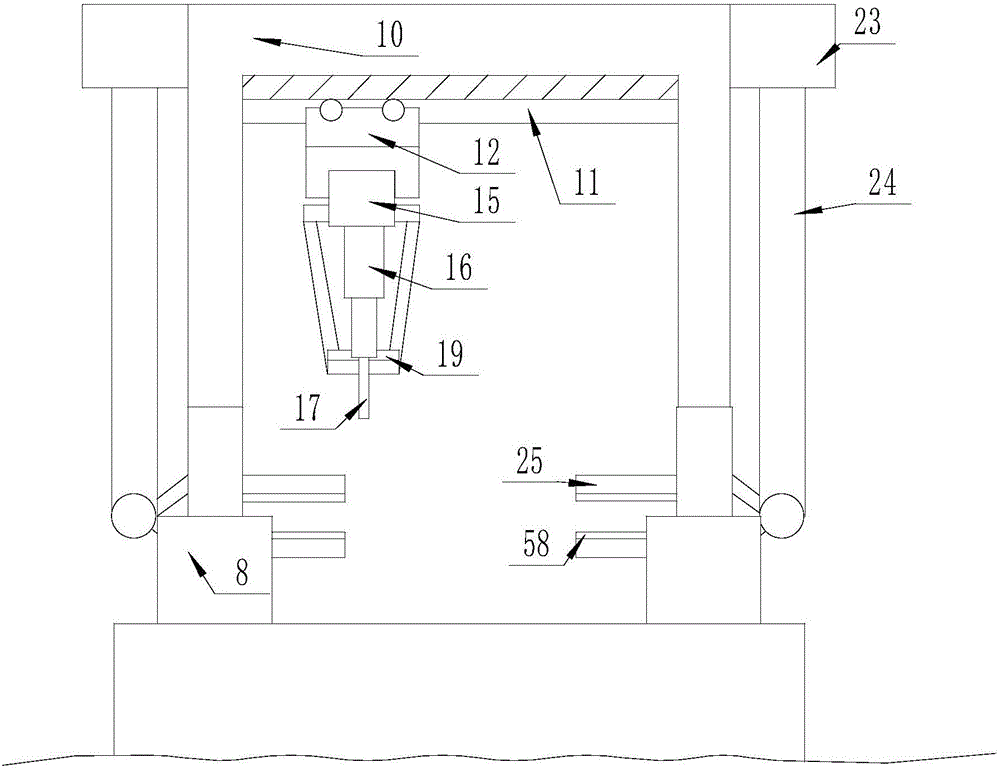

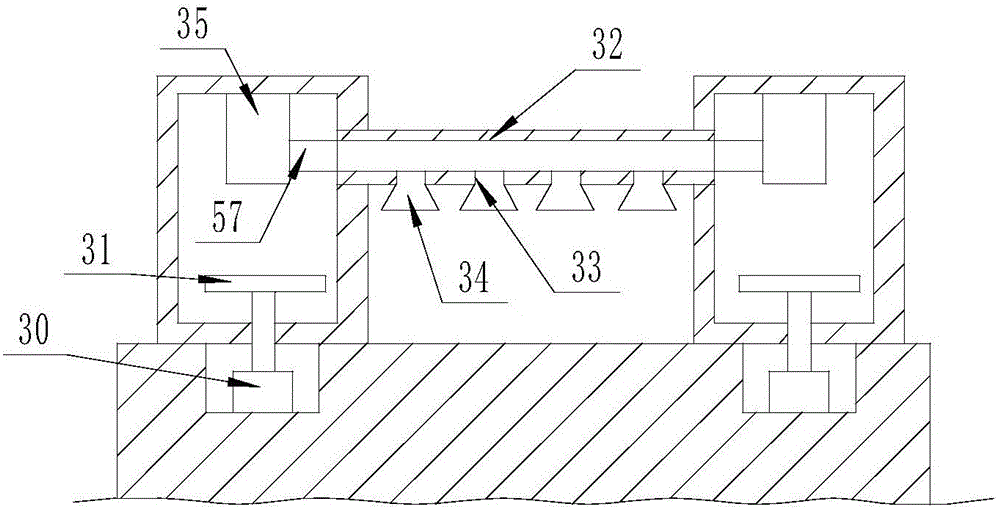

[0023] The present invention will be described in detail below with reference to the drawings, such as Figure 1-7 As shown, a device for cutting fabric burrs includes a mounting base (1). The upper surface of the mounting base (1) is opened with a rectangular groove (2), and the rectangular groove No. 1 (2) An operating workbench (3) is embedded, the installation base (1) has a hollow structure, and there is a debris collection port (4) on the side surface of the installation base (1). The No. 1 debris collection port (4) is embedded with a sliding door (5), the sliding door (5) is provided with a handle (6), and the mounting base (1) is sequentially arranged from left to right There are spraying mechanism, No. 1 cooling mechanism, printing mechanism, No. 2 cooling mechanism, cutting mechanism and finished product collection mechanism. The cutting mechanism consists of No. 2 rectangular grooves (7) arranged on the operating table (3) and arranged in A set of No. 1 electronica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com