Transverse gateway movement structure

A core and horizontal technology, applied in the field of horizontal barrier core structure, can solve the problems of unreasonable deceleration structure of the reducer, difficult to guarantee the working performance, complex and cumbersome overall structure, etc., to achieve increased space utilization and fast transmission response , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

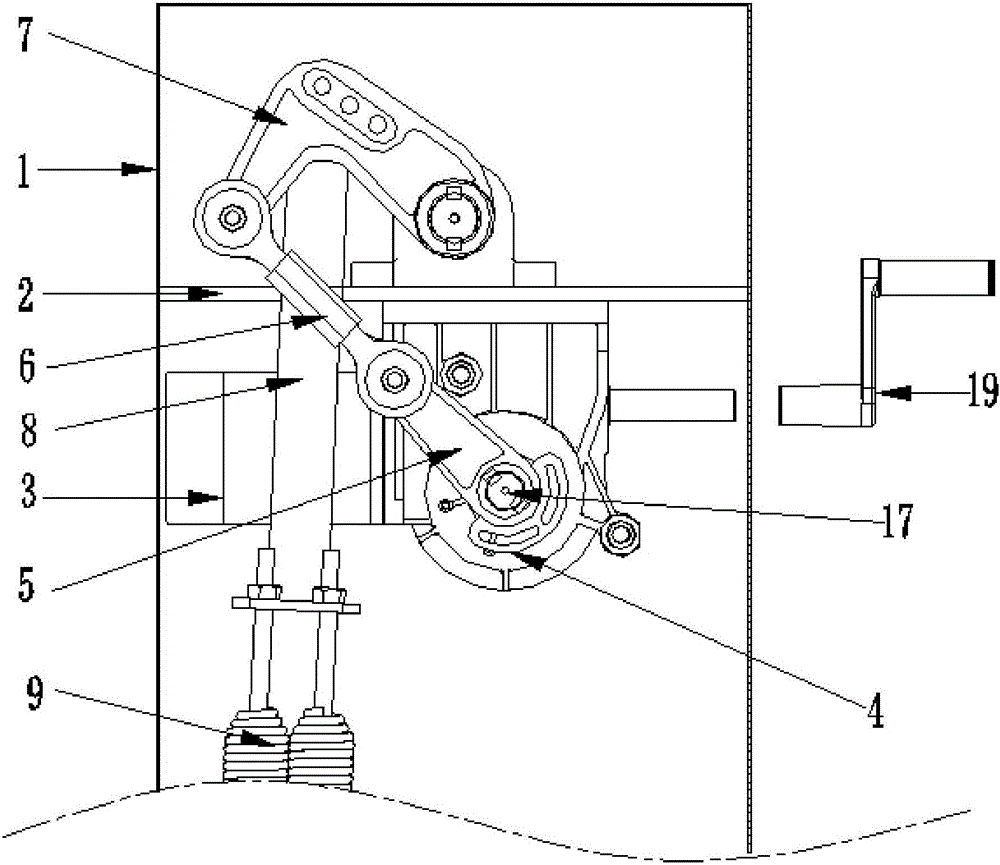

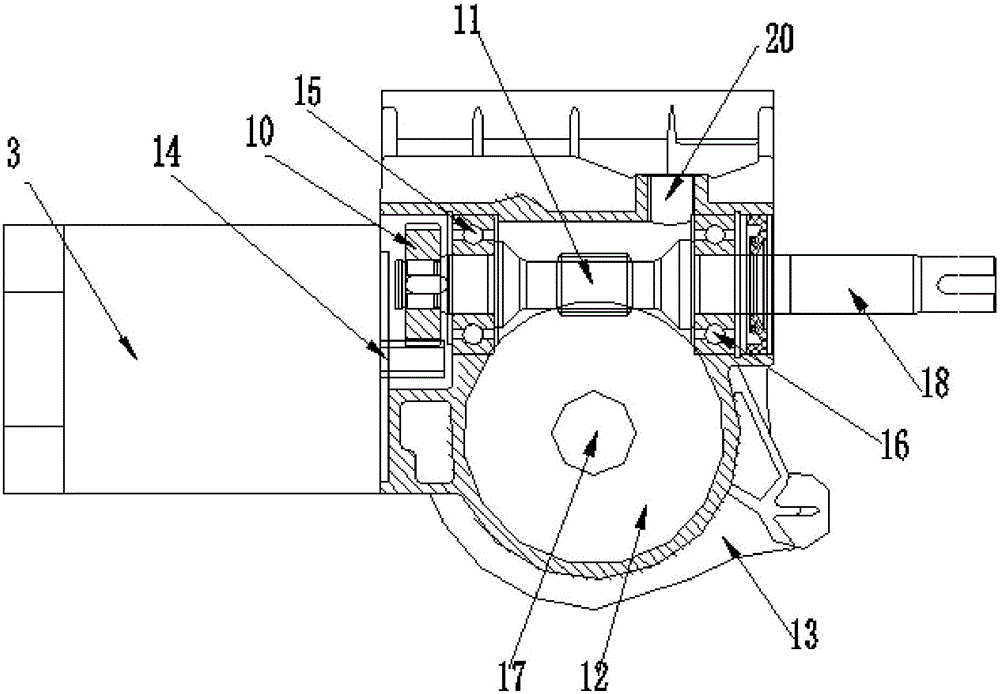

[0018] see Figures 1 to 2 , the movement structure of the horizontal barrier gate provided in this embodiment includes a chassis 1, a movement transmission mechanism and a connecting rod transmission mechanism, and the movement movement mechanism and the connecting rod transmission mechanism are arranged in the chassis 1, wherein the machine The core transmission mechanism is fixedly arranged through the movement fixed plate 2, and one end of the connecting rod transmission mechanism is connected with the output end of the movement transmission mechanism, and the other end is connected with the gate bar; the movement movement mechanism of the barrier gate includes a motor 3 and the reducer 4, the motor 3 is arranged laterally on the side of the reducer 4.

[0019] Specifically, the connecting rod transmission mechanism includes a first straight connecting rod 5, a second straight connecting rod 6 and a third L-shaped connecting rod 7 which are sequentially hinged, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com