Subsidence control system and method for tube curtain construction of existing shield tunnel under short distance

A technology for shield tunneling and settlement control, which is applied in tunnels, earthwork drilling, mining equipment, etc., to achieve easy operation, good settlement control effect, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

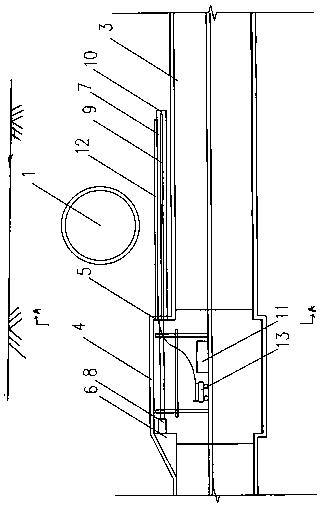

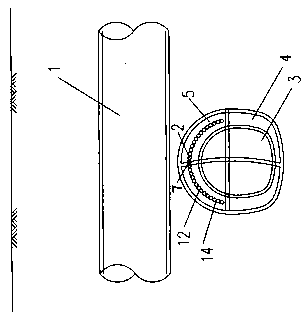

[0029] Example 1: A lock tube curtain steel pipe 7 with an outer diameter of 300 mm and a length of 42 meters is pushed into the soil under the existing shield tunnel 1 in front of the upper end wall 5. During the jacking process, auger The distance between the top end of the rod 9 and the outer end surface of the right port of the lock tube screen steel pipe 7 is maintained at 10 cm, and the volume of the push-in is 3.192 cubic meters, and all the soil in the lock tube screen steel tube 7 is taken out In the measuring soil bucket 11, the measured soil volume is 4.8 cubic meters, and the monitored settlement of the existing shield tunnel 1 is 0.6 mm;

Embodiment 2

[0030] Example 2: Push a lock pipe curtain steel pipe 7 with an outer diameter of 300 mm and a length of 42 meters into the soil under the existing shield tunnel 1 in front of the upper end wall 5, and the end of the spiral drill pipe 9 The end face is in the same cross-section as the outer end face of the right port of the locking tube screen steel pipe 7, and the jacked-in volume is 3.192 cubic meters. The soil body of the locking tube screen steel tube 7 is taken out into the measuring soil bucket 11, and the soil mass is measured. The volume is 5.6 cubic meters, and the settlement of the existing shield tunnel 1 obtained by monitoring is 1.4 mm;

Embodiment 3

[0031] Example 3: Push a lock pipe curtain steel pipe 7 with an outer diameter of 300 mm and a length of 42 meters into the soil under the existing shield tunnel 1 in front of the upper end wall 5, and the end of the spiral drill pipe 9 Extending 10 cm from the outer end surface of the right port of the locking tube screen steel pipe 7, the volume of the jacked-in is 3.192 cubic meters, and all the soil body of the locking tube screen steel tube 7 is taken out into the measuring soil bucket 11, and the soil mass is measured. The volume is 6.8 cubic meters, and the settlement of the existing shield tunnel 1 is 2.0 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com